Automatically adjustable sliding roof for livestock barns

A translational, livestock technology, applied in applications, animal husbandry, poultry cages or houses, etc., can solve the problems of easy tilting of movable flat panels, poor structural stability, uneven force on steel wires, etc., to reduce the breeding of viruses and bacteria , Easy disassembly and operation, and the effect of increasing the incidence rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

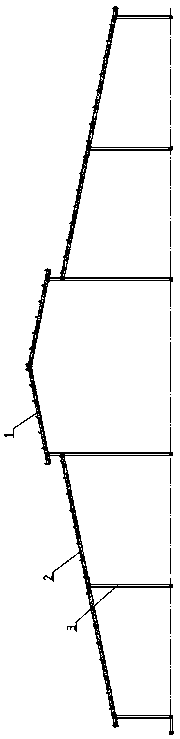

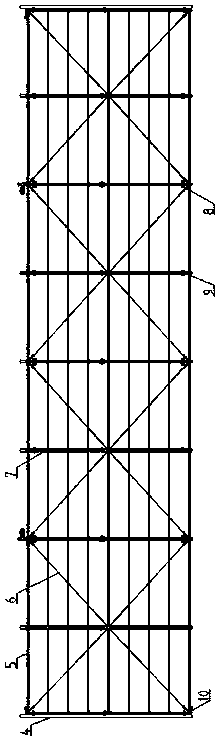

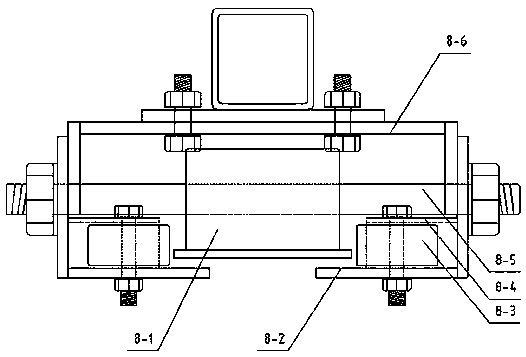

[0035] See attached Figure 1-10 , the roof of this livestock shed disclosed by the present invention mainly includes a ceiling 1, a low shed 2, a support frame 3, a movable beam 4, purlins 5, a tie rod 6, a support beam 7, a first pulley block 8, and a second pulley block 9 , the third pulley block 10.

[0036] The ceiling is a triangular structure arranged symmetrically along the center of the roof width direction, and the low shed is a slope structure arranged on both sides of the roof. As an optimal solution, the slope of the ceiling and the low shed is 15-25%. In addition, it also includes traction drive mechanism.

[0037] Such as Figure 1-2 , the ceiling and the low shed respectively include a support frame and a cover plate. The support frame includes support frames, support beams, purlins and tie rods. The support beams and purlins are arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com