Manufacturing method of personalized retaining splint for department of orthopedics

A manufacturing method and splint technology, applied in fractures, medical science, etc., can solve problems such as inability to meet the force requirements of affected limbs, discomfort for patients to wear, and rough hollowed out structure, so as to prevent insufficient connection strength or inconvenient connection, and make it comfortable to wear , to ensure the effect of portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

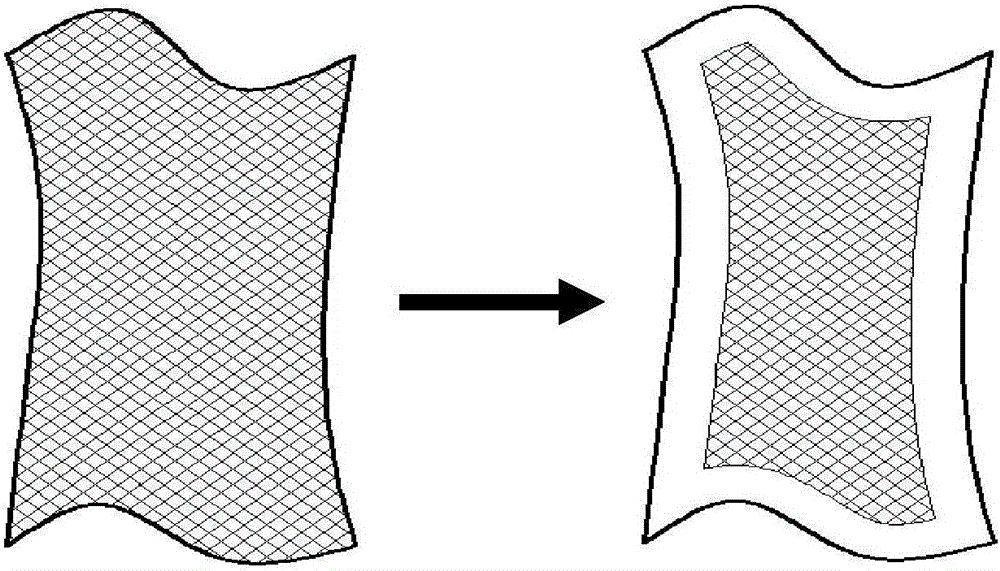

[0040] The manufacturing method of the personalized orthopedic retention splint of the present embodiment comprises the following steps:

[0041] 1) Scan the patient's fracture (taking the wrist as an example) to obtain the limb surface of the patient's fracture.

[0042] In this embodiment, when the fracture is scanned, the two-dimensional image data obtained by CT scanning is used for three-dimensional model reconstruction combined with the original three-dimensional model directly obtained by the optical scanner, and then the surface of the three-dimensional model is obtained, that is, the limb surface of the patient's fracture. Of course, it is also possible to directly use 3D non-contact scanning, or use 2D images such as CT for 3D reconstruction to obtain the original 3D model.

[0043] The data obtained by CT can help to use medical theory to better analyze the affected limb, but the accuracy of its curved surface shape is low, and the data obtained by the optical scann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com