Sickbed support for burn patient

A technology for patients and hospital beds, which is applied in the field of hospital bed supports, can solve the problems of easy feeling of discomfort, high probability of infection, unfavorable wound healing, etc., and achieve the effect of avoiding random movement and improving the stability of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing.

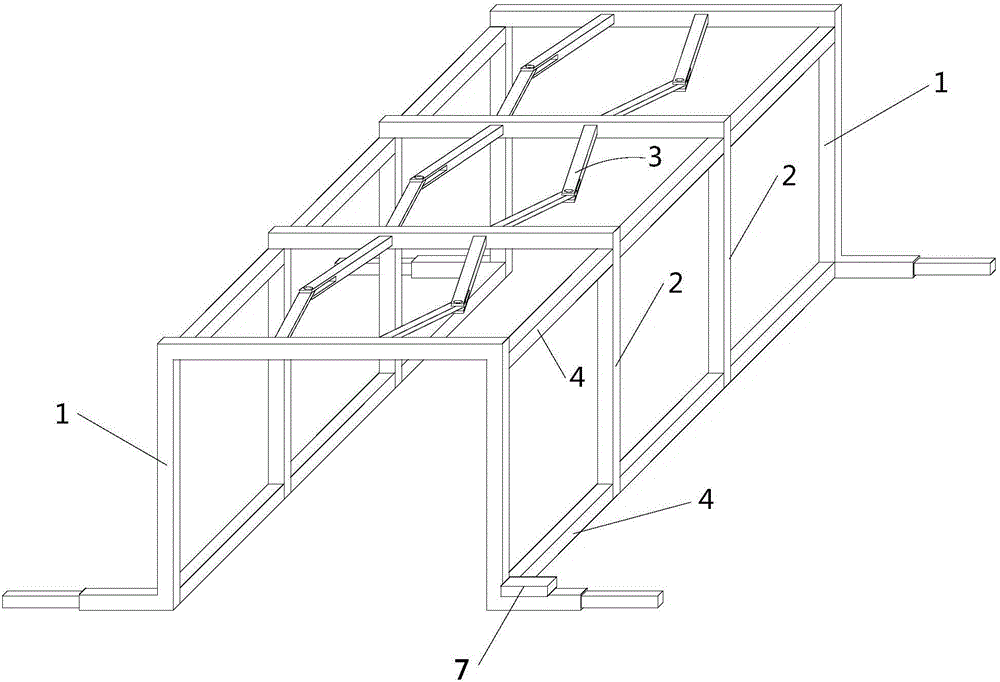

[0025] Such as figure 1 As shown, the hospital bed support for burn patients provided by the embodiment of the present invention includes two parallel and opposite main support frames 1, several auxiliary support frames 1 arranged between the two main support frames 1 and parallel to the main support frames. Support frame 2, the top of the adjacent main and auxiliary support frames and the top of the adjacent auxiliary support frame are all connected by a connecting mechanism 3, the left and right sides of the adjacent main and auxiliary support frames and the left and right sides of the adjacent auxiliary support frame are all connected. Connected by a flexible connecting rod 4.

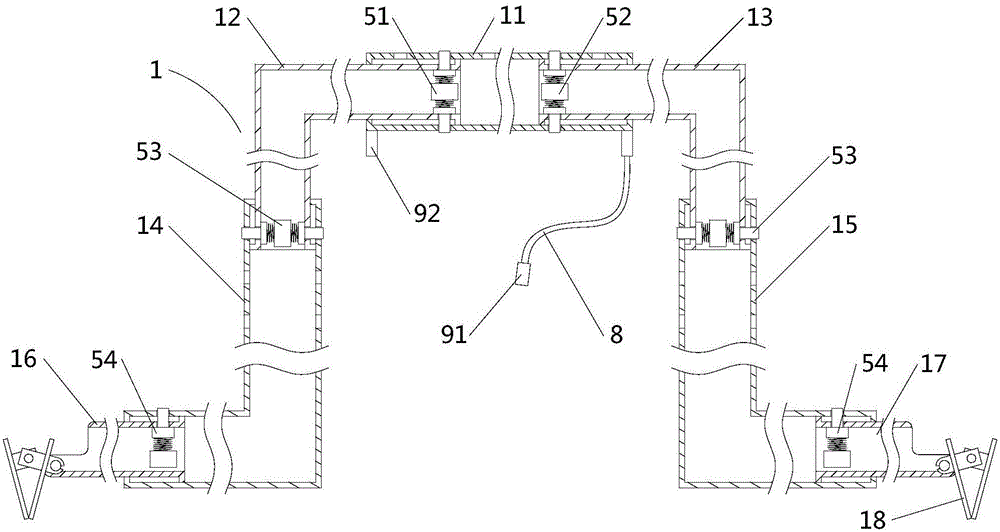

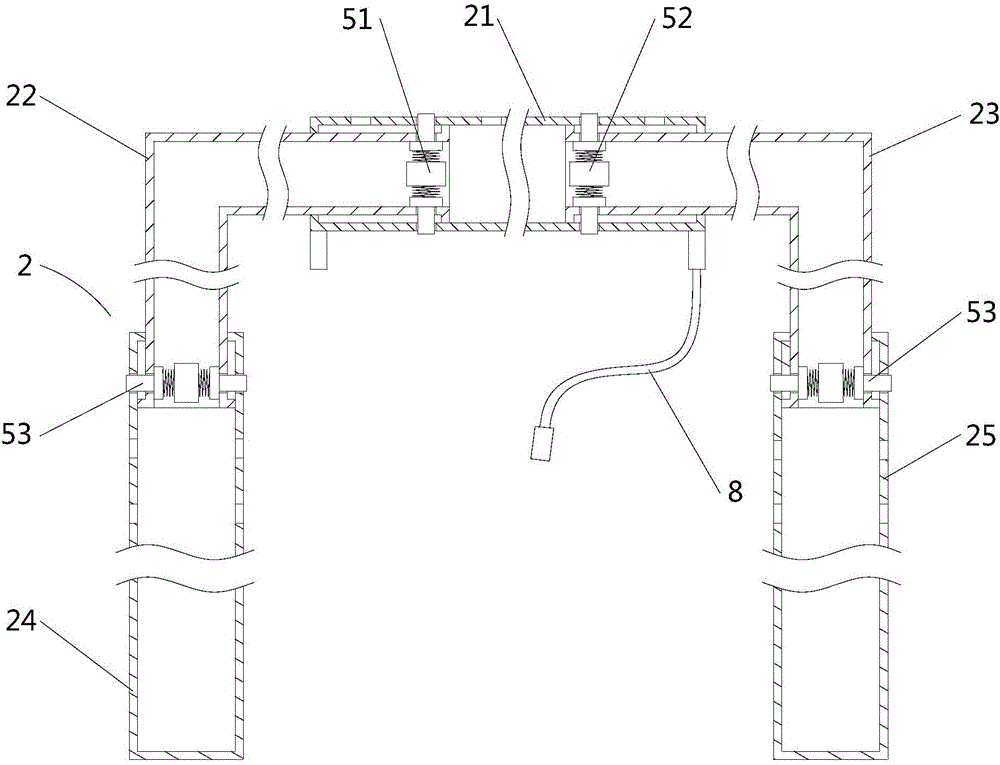

[0026] Such as figure 2 As shown, the main support frame 1 is in the shape of a "several", including a hollow main ejector rod 11, a first folding rod 12 and a second folding rod 13 connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com