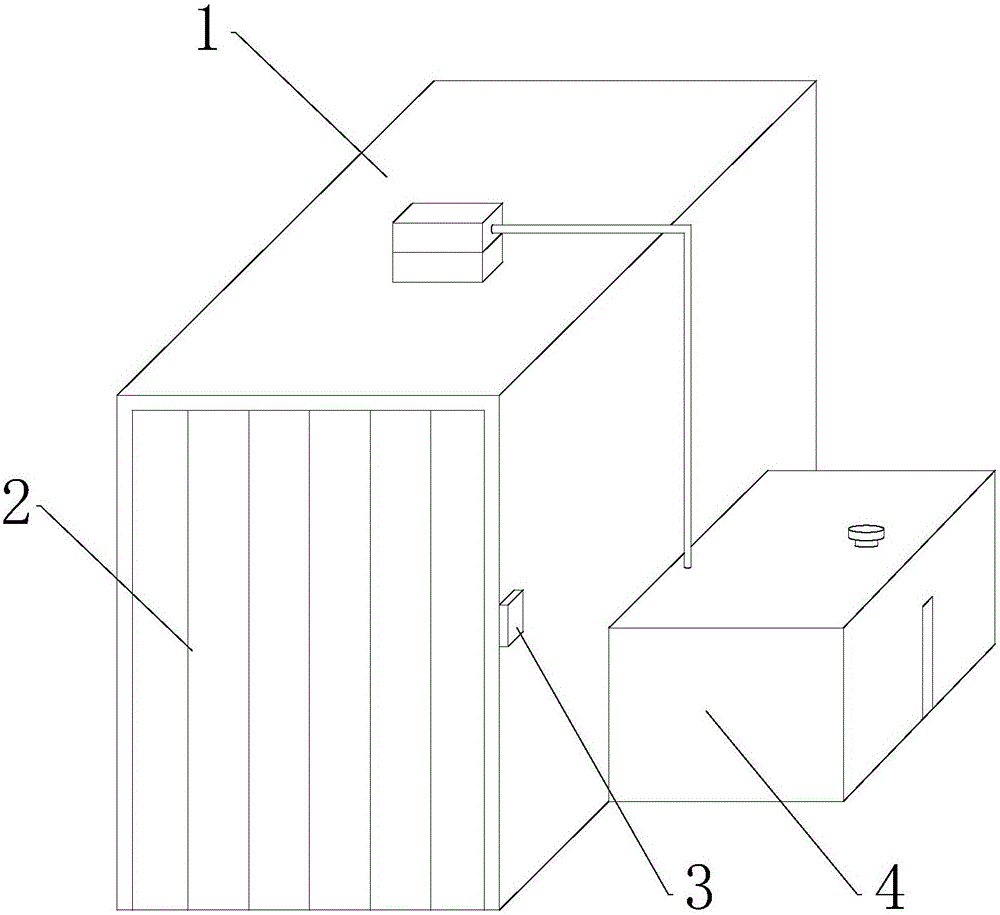

Disinfection channel for livestock farm

A technology for breeding farms and channels, applied in disinfection, sanitary equipment for toilets, water supply devices, etc., can solve the problems of inability to determine the amount of medicinal liquid used, the effect of medicinal liquid is reduced, and the disinfection effect is poor, and achieves good disinfection effect. Disinfection effect, effect of preventing liquid precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

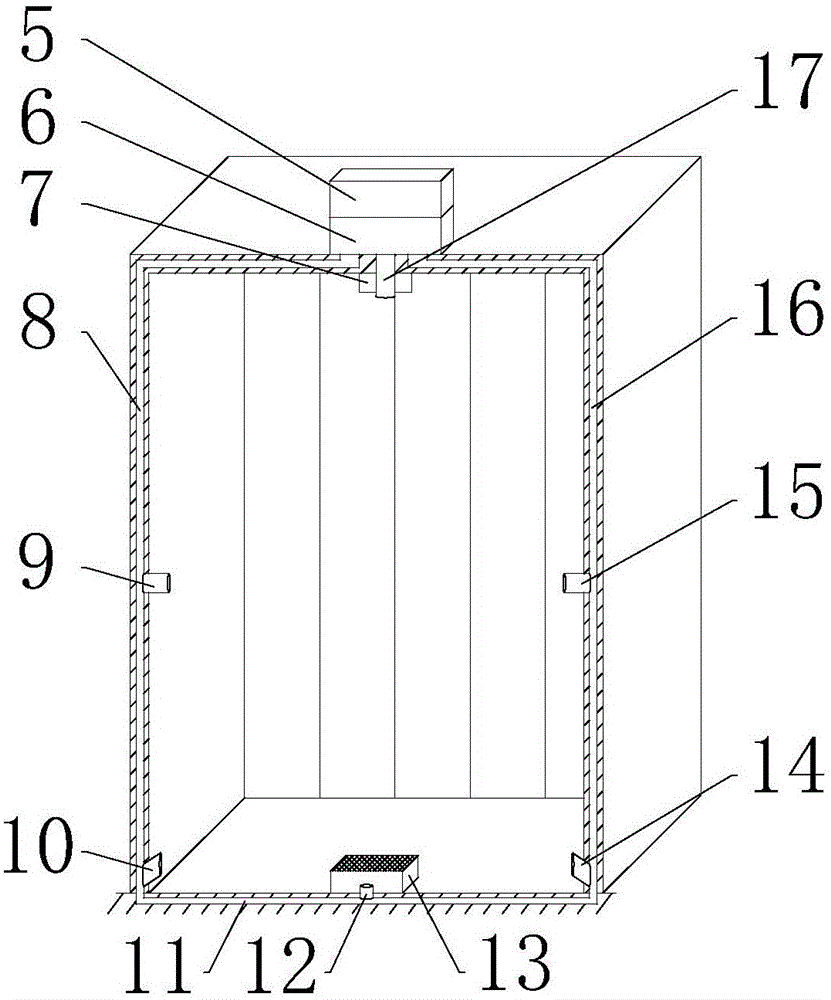

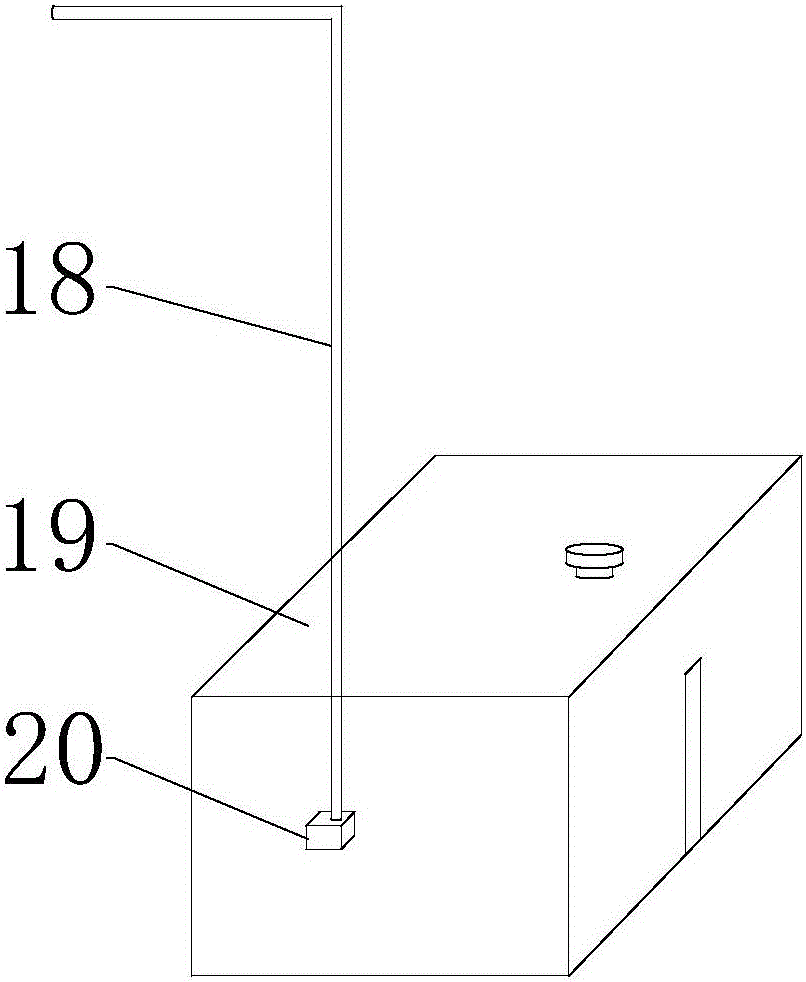

[0026] Specific implementation method: the personnel who want to enter the farm, first open the transparent plastic door curtain 2 at the front end, enter the inside of the disinfection channel device 1, and the personnel stand on the platform device 13, and the infrared sensor 7 collects the information and sends it to the control processor The single-chip microcomputer on 3 performs conversion and processing. If the result is someone, the control processor 3 sends a control command, and the power transmission device 21 receives the command, drives the stirring device 22 to start stirring the liquid medicine, prevents the liquid medicine from settling, and then sucks the liquid medicine pump 20 After receiving the instruction, it also starts to work, and transports the liquid medicine stored in the liquid medicine tank 19 to the liquid medicine atomizer 5 through the liquid medicine pipeline 18, and the liquid medicine atomizer 5 atomizes the medicine liquid to realize automati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com