Elevated overflow tank pre-aeration oxidation ditch sewage treatment system

A sewage treatment system and overflow tank technology, which is applied in water/sewage multi-stage treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of low sewage concentration and unsuitable for higher concentration sewage purification and other problems, to achieve the effect of eliminating sediment, reducing floating sludge and odor, and improving purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

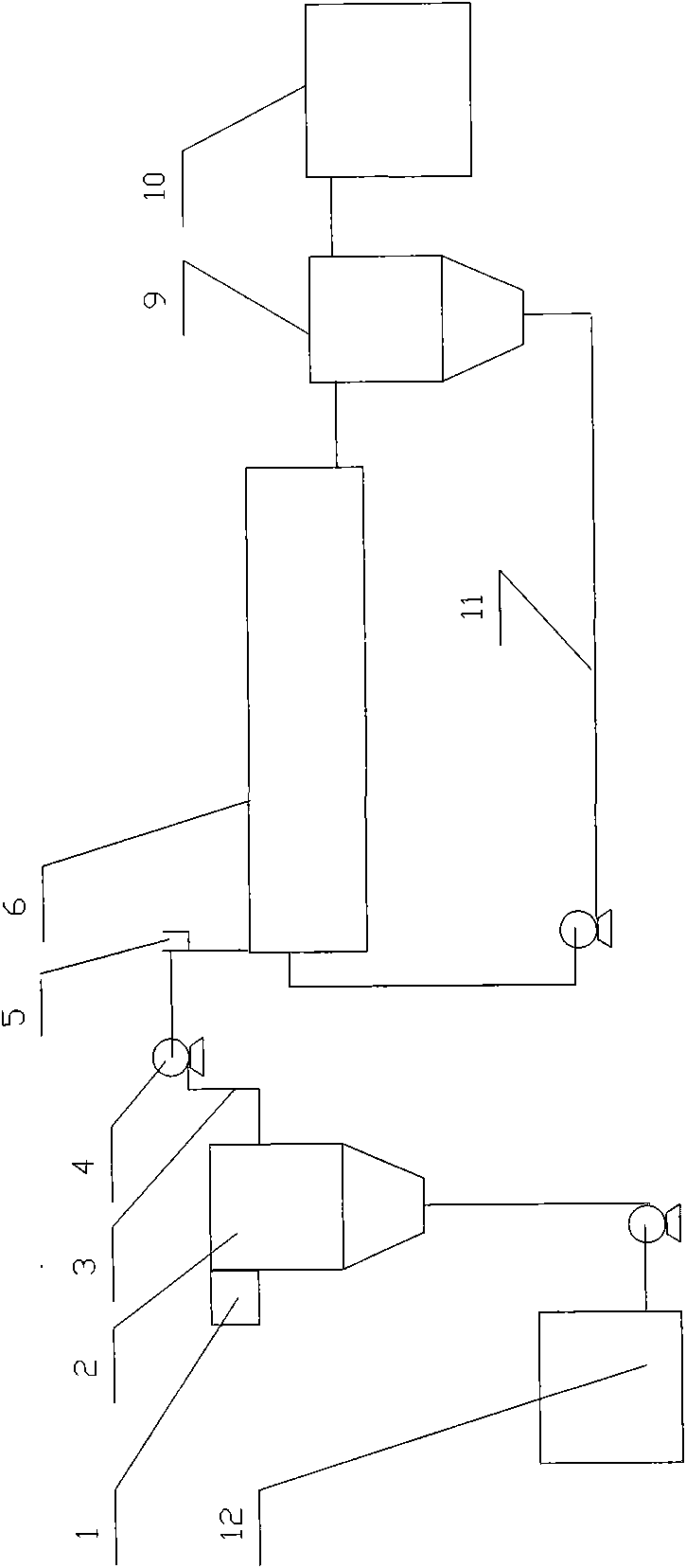

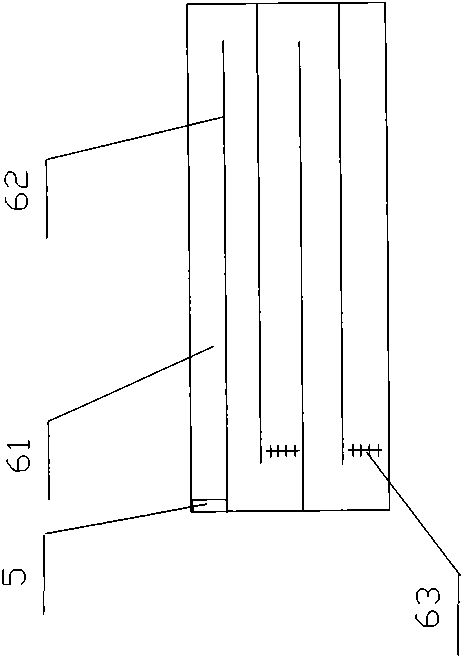

[0010] see figure 1 , the present invention provides an oxidation ditch sewage treatment system with pre-aeration of a high-level overflow tank, comprising a grid 1, a water collection sedimentation tank 2 and an oxidation ditch 6 connected in sequence, and the water inlet end of the oxidation ditch is provided with a high-level The overflow tank 5, the outlet water of the water collection and sedimentation tank is pumped into the high-level overflow tank through the sewage pump 4 on the water outlet pipeline 3, and the overflow port of the high-level overflow tank is located at the water inlet of the artificial wetland above the constructed wetland water surface, the overflow weir is a horizontal weir whose extension width is less than or equal to the width of the constructed wetland water inlet end located below it.

[0011] The sewage first enters the water collection and sedimentation tank through the grille, and the water collection and primary sedimentation are combined ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com