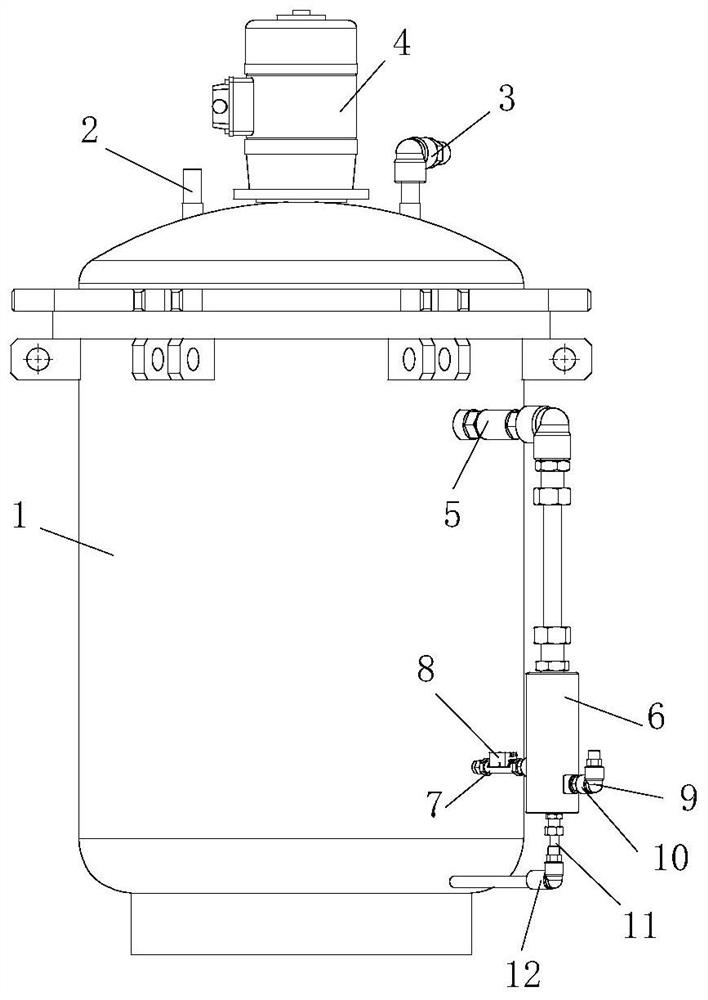

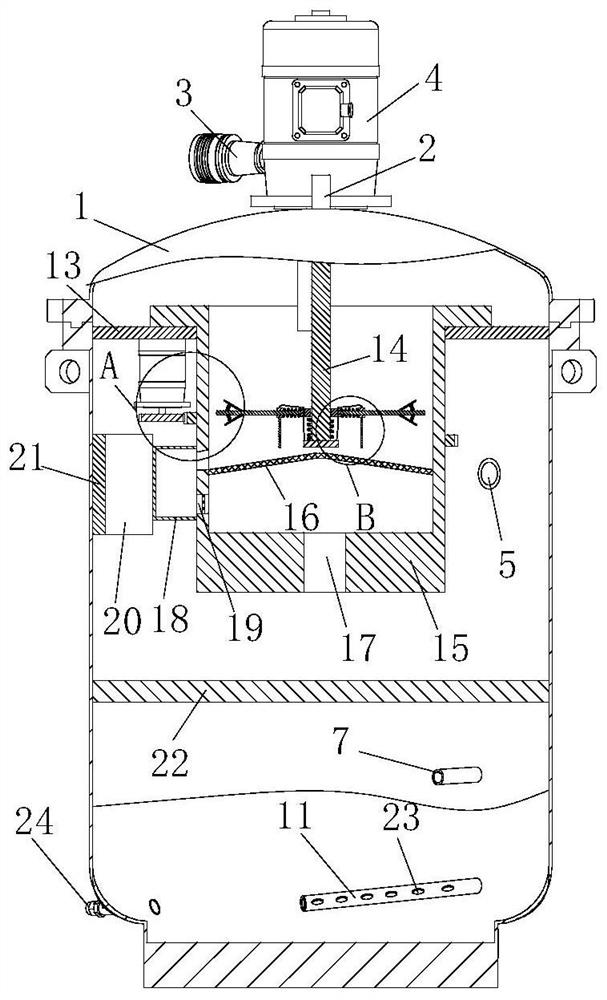

An automatic sewage treatment tank

A sewage treatment tank and automatic technology, which can be used in water/sewage multi-stage treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc. requirements and other issues to achieve the effect of improving sewage treatment effect, improving efficiency and increasing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

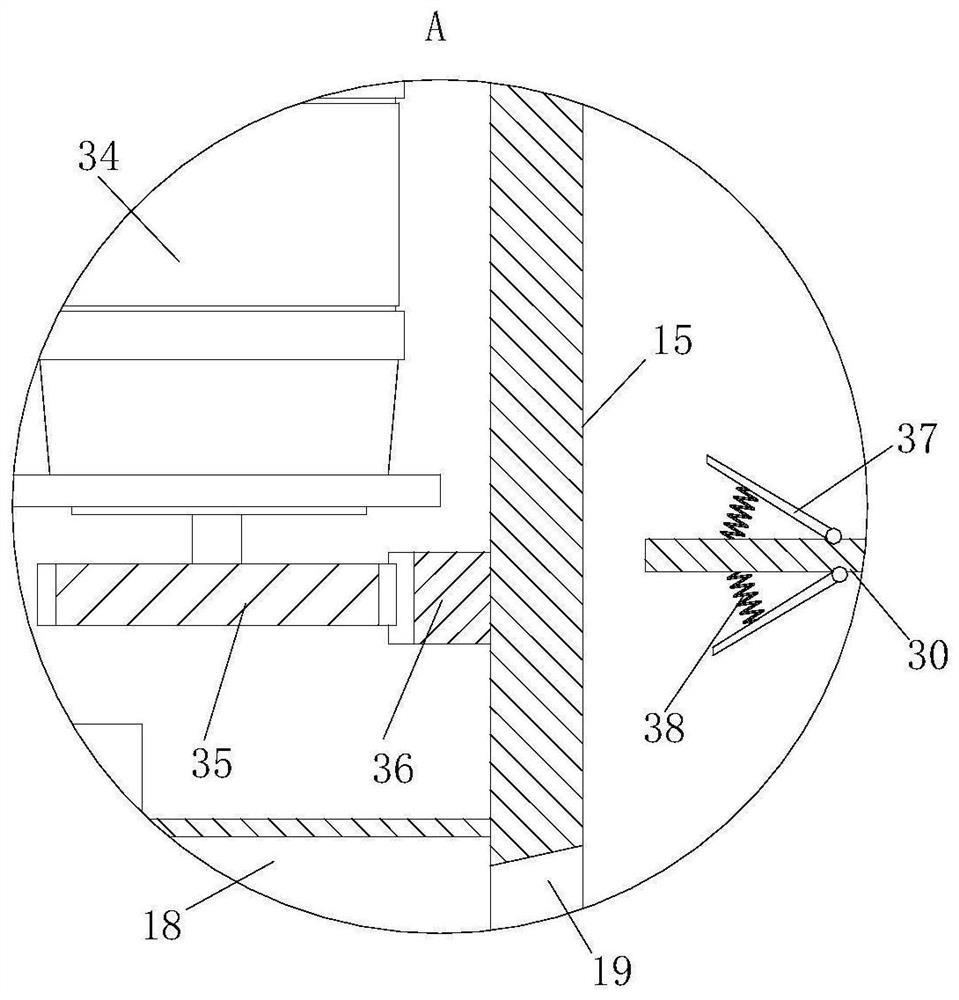

[0028] As an embodiment of the present invention, the lower end of the rotating shaft 14 is fixedly provided with a stopper 25, and the rotating shaft 14 above the stopper 25 is fitted with a shaft sleeve 27, and the shaft sleeve 27 and the stopper 25 are provided with The first spring 26; the main stirring rod 30 is fixedly arranged on the shaft sleeve 27, the main stirring rod 30 is covered with a sliding sleeve 31, and the lower end of the sliding sleeve 31 is fixedly provided with a vertically arranged push plate 33, so A second spring 32 is arranged between the sliding sleeve 31 and the shaft sleeve 27; the side of the shaft sleeve 27 close to the main stirring rod 30 is provided with a wire hole 28 penetrating up and down, and the sliding sleeve 31 is fixedly provided with a traction rope 29. The traction rope 29 passes through the wire hole 28 and is connected to the block 25. Through the setting of the second spring 32 and the sliding sleeve 31, the sliding sleeve 31 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com