System and method for sand-gravel strata foundation pit precipitation and excavation construction

A technology for foundation pits and strata, applied in excavation, infrastructure engineering, construction, etc., can solve the problems of large impact on the surrounding environment and difficult construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

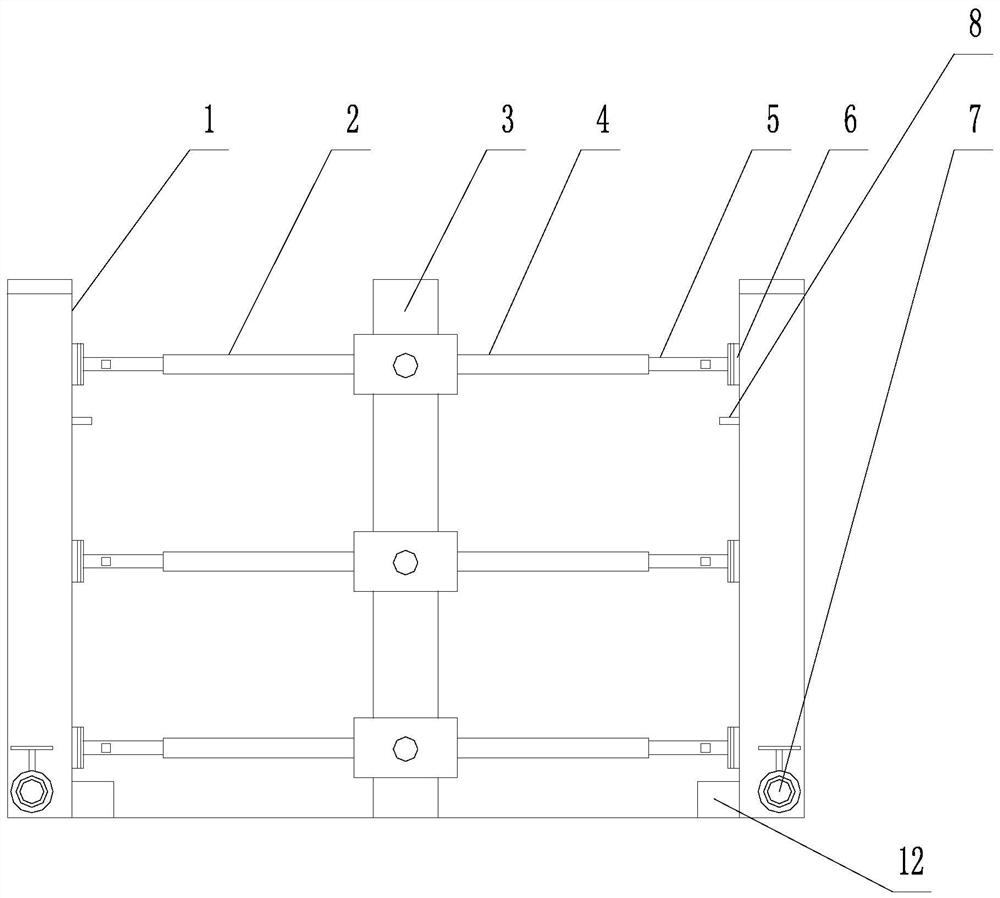

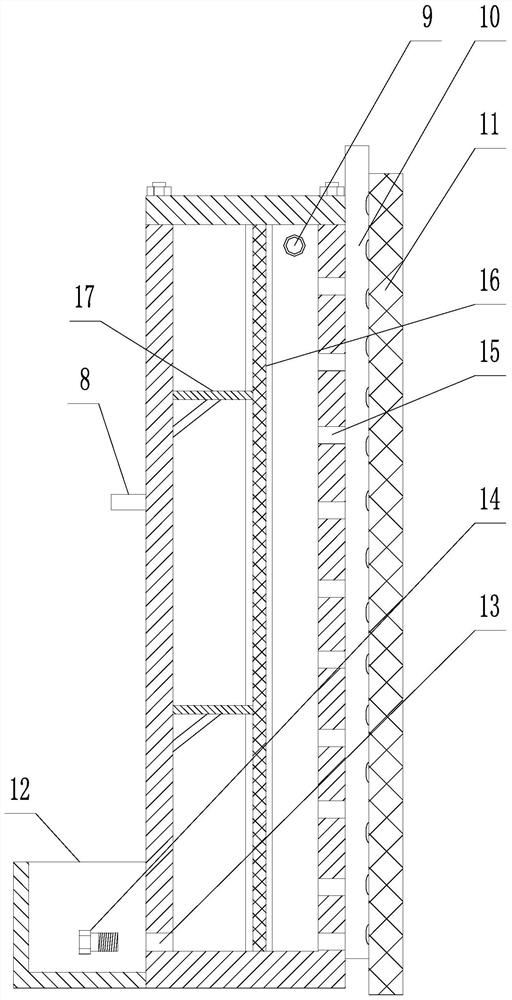

[0045] Such as figure 1 and figure 2 As shown, the system for foundation pit dewatering and excavation construction in sand egg formation includes a foundation pit support assembly, and the foundation pit support assembly includes a shroud 1, and the shroud 1 is a hollow plate-like structure;

[0046] The coaming plate 1 includes an outer plate for connecting with the foundation pit and an inner plate close to the center of the foundation pit, and the outer plate is provided with a plurality of communication holes 15 passing through the inner and outer sides of the outer plate;

[0047] The inner side plate is provided with a drain port 13 that runs through the inner and outer sides of the inner plate, and the fluid conduction capacity of the drain port 13 is adjustable;

[0048] It also includes a water tank 12 fixed on the inner board, and the outlet end of the drain port 13 is located in the water tank 12 .

[0049] This scheme aims at the problems that exist in the cons...

Embodiment 2

[0054] Such as figure 1 and figure 2 As shown, this embodiment is further limited on the basis of Embodiment 1: as a specific solution for the adjustable fluid conduction capacity of the drain port 13, it is set as follows: the number of the drain port 13 is multiple, and some Or the blocking state of all drain ports 13 is adjustable. In this solution, a plurality of drain outlets 13 are used to form the coaming 1 to adjust the outlet water flow, and the specific adjustment method adopts the method of blocking part of the drain outlets 13 . During specific use, if the drainage of the foundation pit does not meet the safety requirements, the state where the above drainage outlets 13 are all blocked can be adopted.

[0055] When this scheme is actually implemented, in order to realize that the drainage flow rate of the coaming 1 through the drainage outlet 13 is multi-gradient adjustable, it is preferable to set the number of drainage outlets 13 as much as possible. Water ca...

Embodiment 3

[0070] This embodiment discloses a method for dewatering and excavating a foundation pit in a sand egg formation. The method is based on the system described in any one of the above embodiments. The method is implemented through the following steps:

[0071] S1, on the wall surface of the excavated foundation pit, a steel mesh 11 is set as the internal steel structure skeleton of the concrete wall;

[0072] S2. Arrange a plurality of grouting pipes 10 on the outer wall of the steel mesh 11, the grouting pipes 10 are arranged at intervals, and the gap between adjacent grouting pipes 10 serves as a fluid flow channel between the inlet end of the communication hole 15 and the steel mesh 11 , the grouting pipe 10 is arranged with a plurality of grouting holes along the axis, and the openings of the grouting holes face the steel mesh 11;

[0073] S3, complete the erection of the coaming plate 1, and the outer wall of the outer plate is attached to the grouting pipe 10;

[0074] S4. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com