Aquatic product ultrasonic automatic cleaning system and control method thereof

A technology for automatic cleaning and aquatic products, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve problems such as incomplete cleaning, unclean, cumbersome cleaning, etc., and achieve more convenient and thorough cleaning. Good ultrasonic effect, water saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

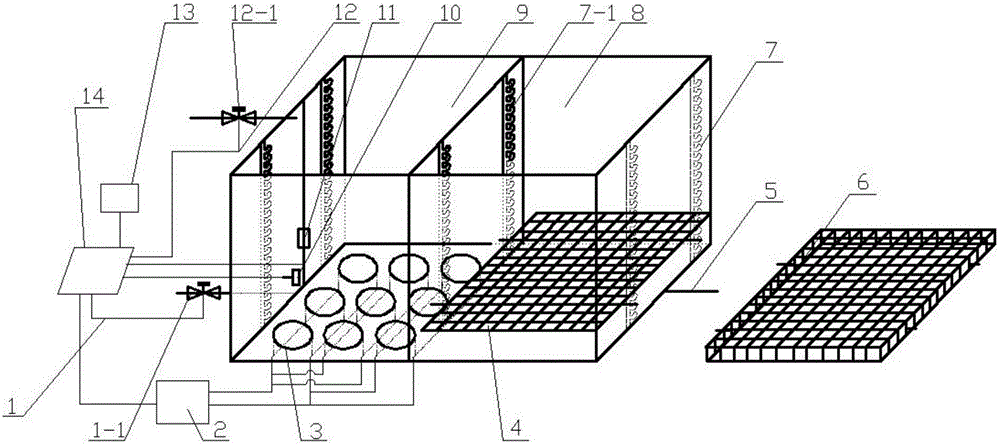

[0029] Embodiment one: if figure 1As shown, the present invention includes a cleaning tank 9 and a draining tank 8, the cleaning tank 9 is connected with the tap water inlet pipe through the water inlet pipeline 12, the cleaning tank 9 is connected with the sewer through the outlet pipeline 1, and the draining tank 8 is connected through the draining tank outlet pipeline 5 is connected to the sewer, the cleaning tank 9 is provided with a liquid level sensor 11 and a turbidity sensor 10, the liquid level sensor 11 is electrically connected with the turbidity sensor 10 and the controller 14, and several transducers are provided at the bottom of the cleaning tank 9 3. The transducer 3 is electrically connected to the ultrasonic generator 2, and the ultrasonic generator 2 is electrically connected to the controller 14 at the same time. The side walls of the cleaning pool 9 and the draining pool 8 are all provided with several aquatic product holders. Frame guide rail 7, cleaning p...

Embodiment 2

[0038] Embodiment 2: The present invention includes a cleaning pool 9 and a draining pool 8, the cleaning pool 9 is connected to the tap water inlet pipe through the water inlet pipeline 12, the cleaning pool 9 is connected to the sewer through the outlet pipeline 1, and the draining pool 8 is passed through the draining pool outlet pipe The road 5 is connected to the sewer, the cleaning pool 9 is provided with a liquid level sensor 11 and a turbidity sensor 10, the liquid level sensor 11 and the turbidity sensor 10 are electrically connected with the controller 14, and several transducers are arranged at the bottom of the cleaning pool 9. device 3, the transducer 3 is electrically connected to the ultrasonic generator 2, the ultrasonic generator 2 is electrically connected to the controller 14 at the same time, and several aquatic products are arranged on the side walls of the cleaning pool 9 and the draining pool 8 The cage guide rail 7, the cleaning tank 9 and the drain tank...

Embodiment 3

[0048]Embodiment 3: The present invention includes a cleaning pool 9 and a draining pool 8, the cleaning pool 9 is connected to the tap water inlet pipe through the water inlet pipeline 12, the cleaning pool 9 is connected to the sewer through the outlet pipeline 1, and the draining pool 8 is passed through the draining pool outlet pipe The road 5 is connected to the sewer, the cleaning pool 9 is provided with a liquid level sensor 11 and a turbidity sensor 10, the liquid level sensor 11 and the turbidity sensor 10 are electrically connected with the controller 14, and several transducers are arranged at the bottom of the cleaning pool 9. device 3, the transducer 3 is electrically connected to the ultrasonic generator 2, the ultrasonic generator 2 is electrically connected to the controller 14 at the same time, and several aquatic products are arranged on the side walls of the cleaning pool 9 and the draining pool 8 The cage guide rail 7, the cleaning tank 9 and the drain tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com