Device and method for manufacturing metal bellows

A metal bellows and manufacturing device technology, which is applied in the field of metal bellows manufacturing devices, can solve problems such as low yield and easy occurrence of cracks, and achieve the effects of solving poor plasticity, reducing scrap, and short heating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

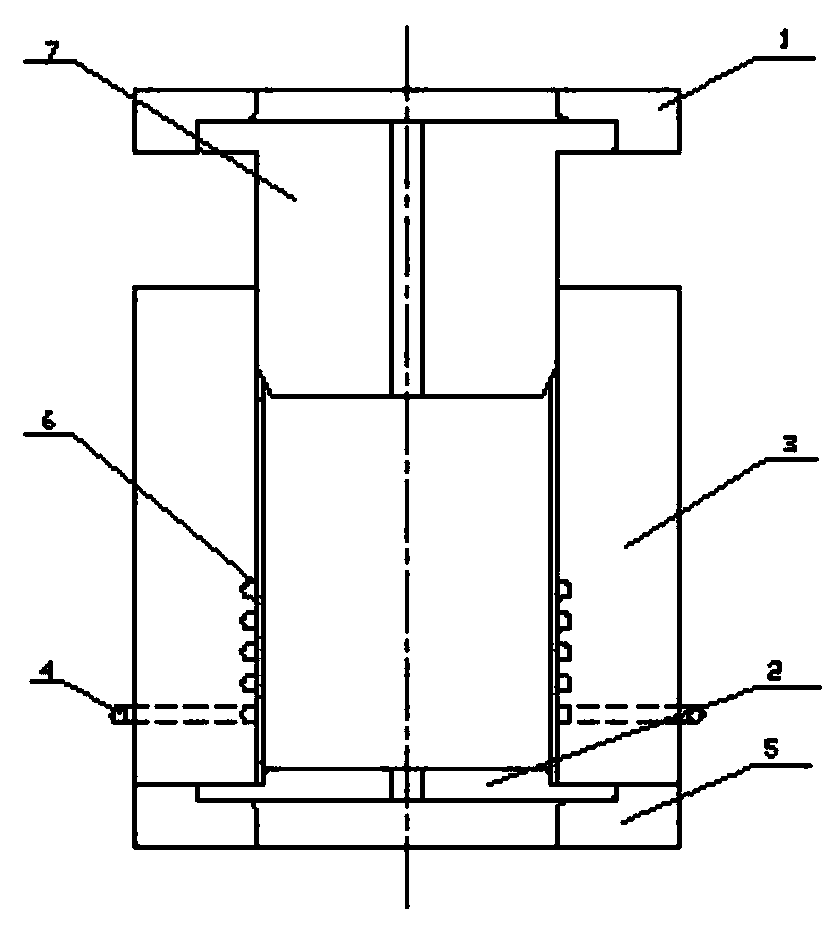

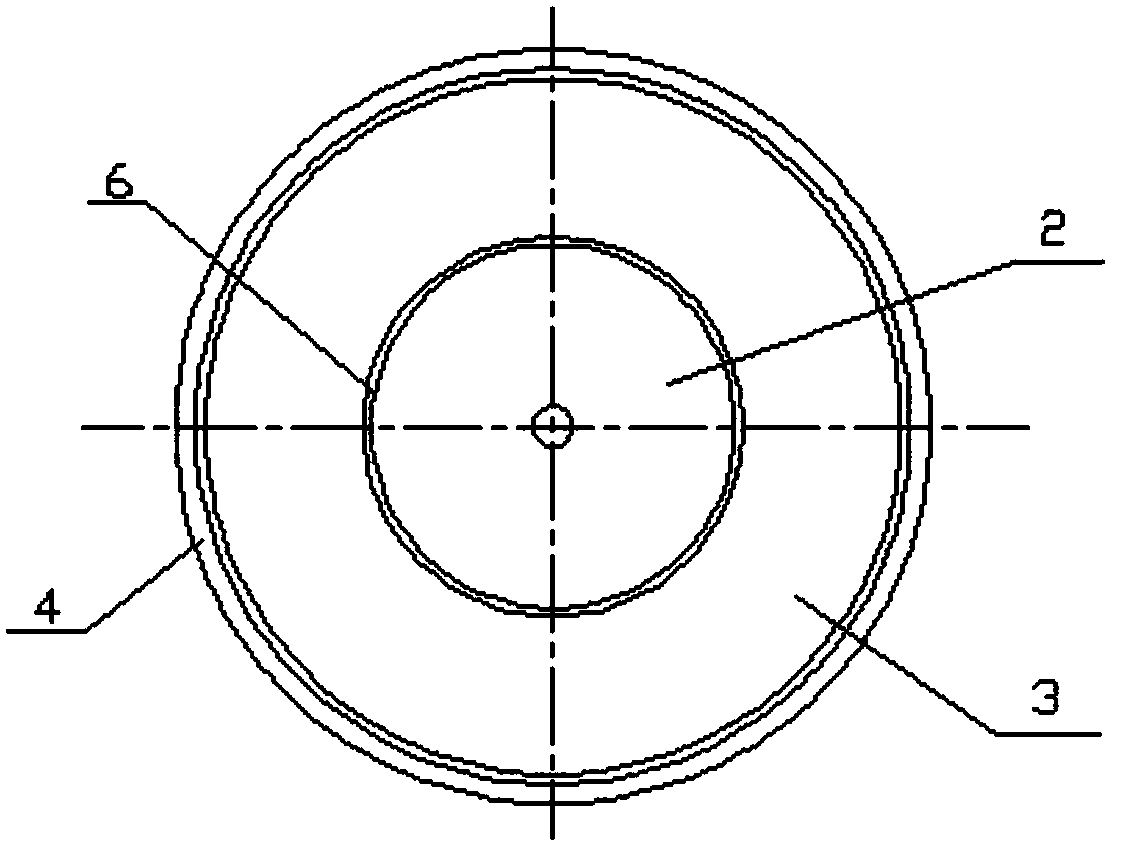

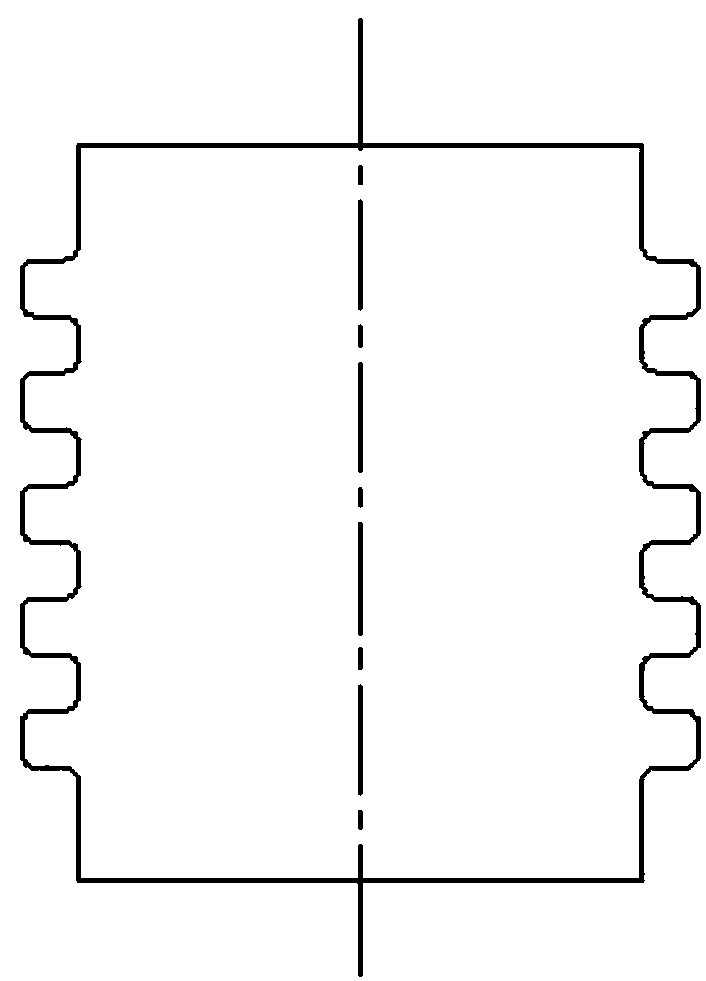

[0025] Please refer to Figure 1 to Figure 3 As shown, the manufacturing device of the metal bellows of the present invention is composed of an upper mold base 1, a first seal 2, a mold 3, a heating wire 4, a lower mold base 5, a metal pipe 6, and a second seal 7, and the mold 3 is arranged on Between the upper mold base 1 and the lower mold base 5, and between the lower mold base 5 and the mold 3 are connected by bolts, the metal pipe 6 is arranged in the mold 3 and the upper and lower ends of the metal pipe 6 are respectively equipped with second seals 7 And the first sealing member 2, the upper end of the second sealing member 7 extends beyond the upper surface of the mold 3 and is connected with the upper mold base 1 by bolts, and the lower end of the first sealing member 2 exceeds the lower surface of the mold 3 And it is connected with the lower mold base 5 by bolts. A round hole (not marked) extending up and down is respectively arranged at the middle position of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com