Fully-automatic intelligent inspection robot

An intelligent inspection and robot technology, applied in the direction of manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems that cannot guarantee timing, fixed-point, quantitative inspection tasks, etc., to achieve reliable real-time detection capabilities, avoid omissions, and ensure the environment safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

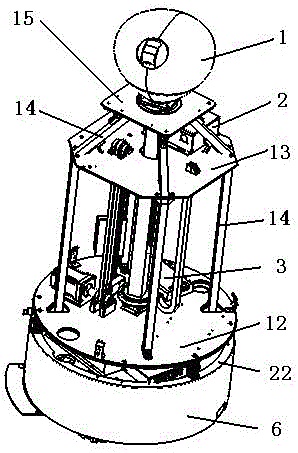

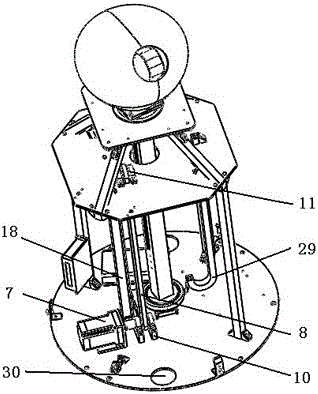

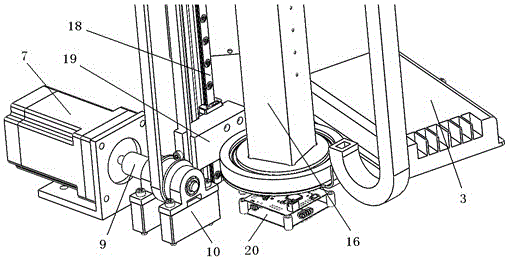

[0022] Such as figure 1 , a fully automatic intelligent inspection robot, which includes an upper image acquisition terminal 1, a lifting device, an attitude controller 2, a gyroscope sensor, a main controller 3, a power supply component, a motion controller 5, a driving device 6 and a remote control platform, wherein: the upper image acquisition terminal 1 is a camera. The lifting device is composed of a driving motor 7, a loop belt 8, a connecting shaft 9, a first bearing block assembly 10, a second bearing block assembly 11, a first fixed disc 12, a connecting disc 13, a connecting frame 14, and a collection end fixed platform. 15. Elevating rod 16, lifting slide rail 18, guide rail and connection block 19 are formed, wherein, first fixed disk 12 and connecting disk 13 are connected by connecting frame 14, and first fixed disk 12 after connection is parallel to connecting disk 13.

[0023] The connection plate 13 is connected with the collection end fixed platform 15 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com