A kind of transportation technology of riprap leveling ship pile leg barge

A technology of riprap leveling and pile legs, used in transportation and packaging, barges/barges, external frames, etc., can solve the problems of width requirements of transport barges, frequent lifting mechanism operations, long leg lengths, etc., to increase stability. The effect of sexual safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

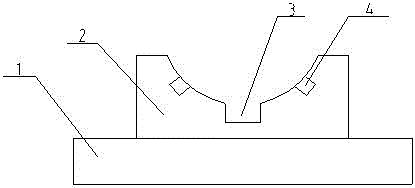

Image

Examples

Embodiment Construction

[0016] The invention discloses a riprap screed ship pile leg barge transportation process. The lifting mechanism of the riprap screed ship belongs to a heavy-duty open rack and pinion transmission structure, which is similar to a jack-up drilling platform. According to the pile leg requirements of the jack-up drilling platform, the number of pile insertion / extraction on the platform shall not exceed 5 times a year; while the lifting mechanism of the leveling ship operates frequently, the leveling ship needs to insert / extract at least 5 piles during the construction of each pipe section. 8 times, with an average of more than 80 times of plugging and pulling piles per year.

[0017] The geological conditions in the screed operation sea area are complex, the working conditions of plugging piles are harsh, and the rack and pinion are in low speed, heavy load, and impact conditions for a long time. The wear value has exceeded the design allowable value. The maximum wear amount meas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com