Column type and pyramid-tube type coupled photoproduction reactor, application and culture method

A technology of tubular reactor and column reactor, applied in photobioreactor, bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, etc., can solve the flow diffusion performance and mass transfer. Problems such as poor thermal performance and low utilization of light, to ensure the acquisition of light energy, strengthen the mass transfer process, and eliminate the effect of light shading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

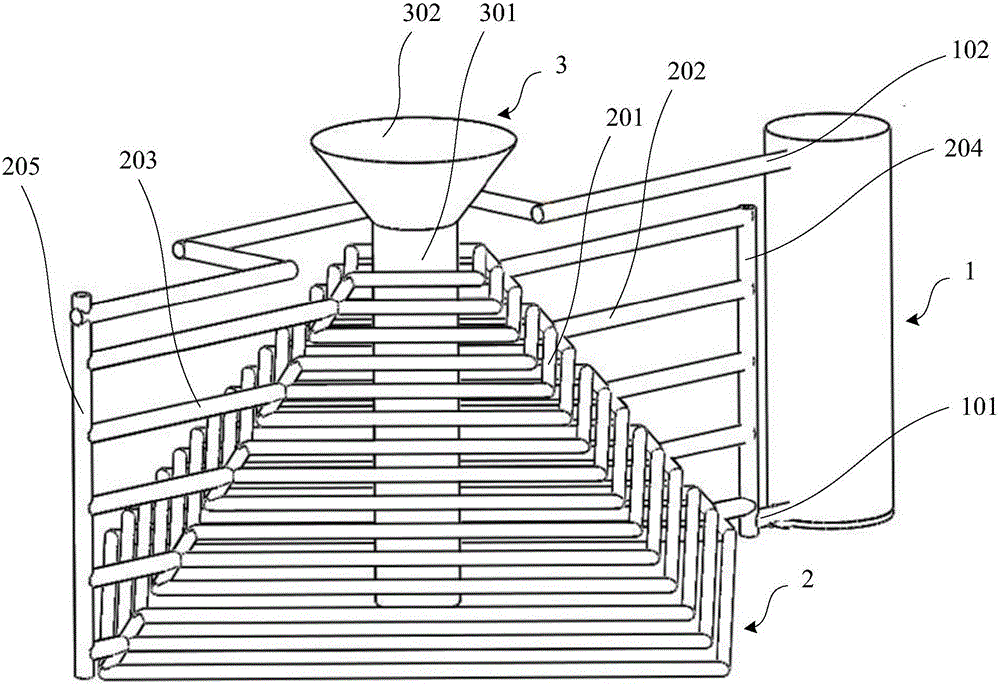

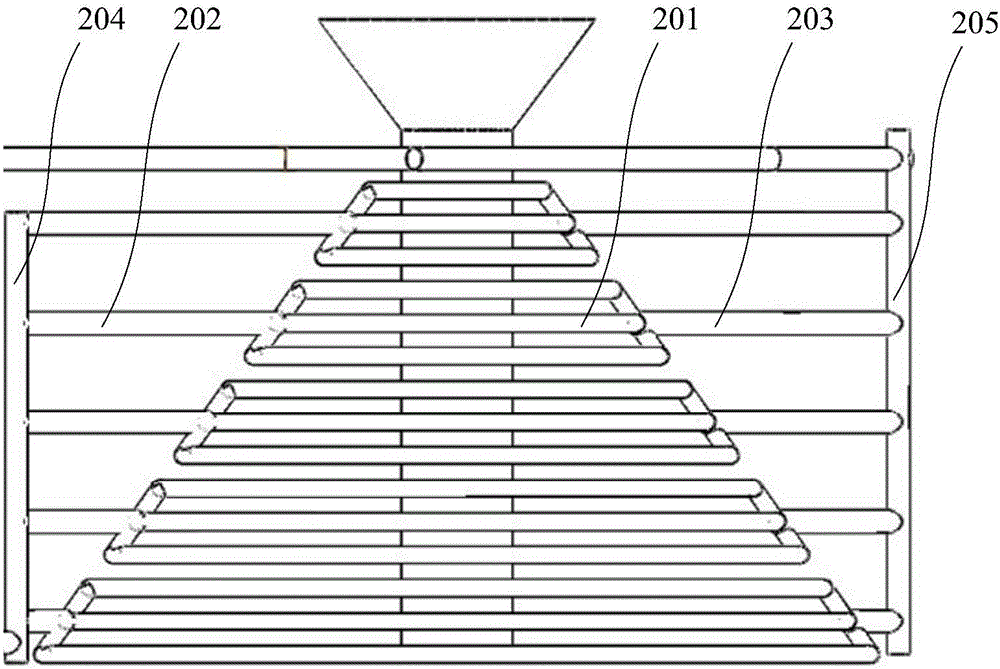

[0077] The present invention provides a column coupling pyramid tube photogenerated reactor, please refer to figure 1 , which is a schematic diagram of the three-dimensional structure of the photogenerated reactor, including a column reactor 1 and a pyramid tube reactor 2 . figure 2 Shown is a side view of the pyramidal tube reactor.

[0078] Specifically, the column reactor 1 can be, but not limited to, cylindrical or polygonal, and at least a part of it is made of transparent material, such as plexiglass, so that light can penetrate into the column reactor and be utilized.

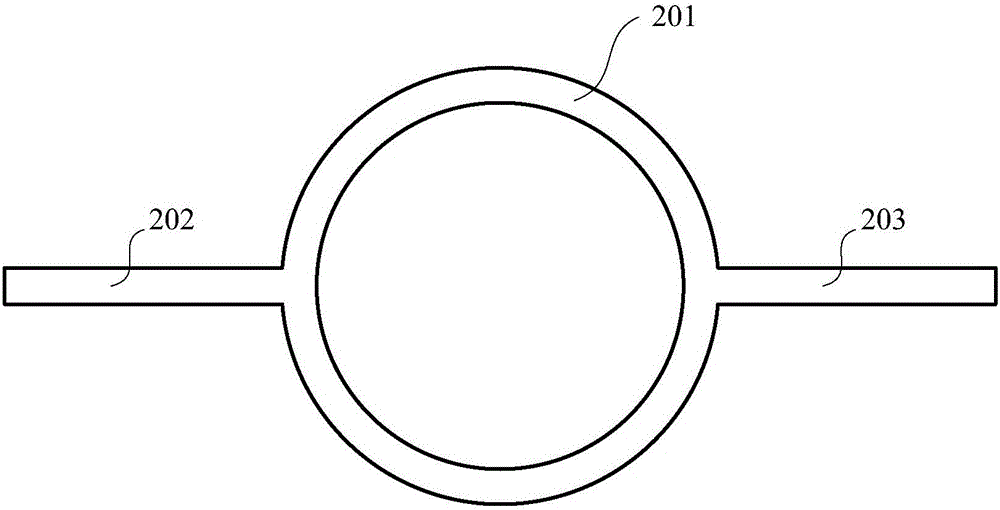

[0079] Concrete, described pyramid tube reactor 2 comprises:

[0080] At least two layers of reaction rings 201 accumulated sequentially from bottom to top; wherein, the circumference of the reaction ring located in the lower layer is greater than the circumference of the reaction ring located in the upper layer;

[0081] The stratified inflow manifold 202 and stratified outflow manifold 203 respectiv...

Embodiment 2

[0103] The present invention also provides an application of a photo-generated reactor, the photo-generated reactor adopts the column-type coupled pyramid tube-type photo-generated reactor described in Embodiment 1.

[0104] Specifically, the application may also be microbial cultivation, chemical reaction vessels, biological purification of environmental pollutants, etc. in the fields of biology, chemical engineering, and the environment.

[0105] As an example, the application is the use of the photoreactor for microalgae cultivation and CO 2 fixed.

Embodiment 3

[0107] The present invention also provides a culture method, please refer to Figure 8 , is shown as an operation flow chart of the culture method, comprising the following steps:

[0108] S1: will contain CO 2 The gas transported to the total inflow manifold of the pyramid tube reactor;

[0109] S2: Utilize the propelling effect of the air flow and the circulation pump to make the alga liquid in the total inflow manifold flow to the layered inflow manifold, and further flow into the reaction rings of each layer of the pyramid tube reactor, and the gas mix well;

[0110] S3: using at least one of natural light source and artificial light source as a light source to make the algae liquid carry out photosynthesis in the reaction ring under light conditions.

[0111] As an example, see Figure 9 , shows the pipeline connection diagram of the photoreactor used in the cultivation method of the present invention. As shown in the figure, the photogenerated reactor and circulatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com