Preparation method of antistatic modified PBT fiber

An antistatic and modified technology, applied in the direction of conductive/antistatic filament manufacturing, fiber chemical characteristics, rayon manufacturing, etc., can solve the problems that limit the application field of polyester fiber, and achieve improved mechanical strength, easy control, and performance stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

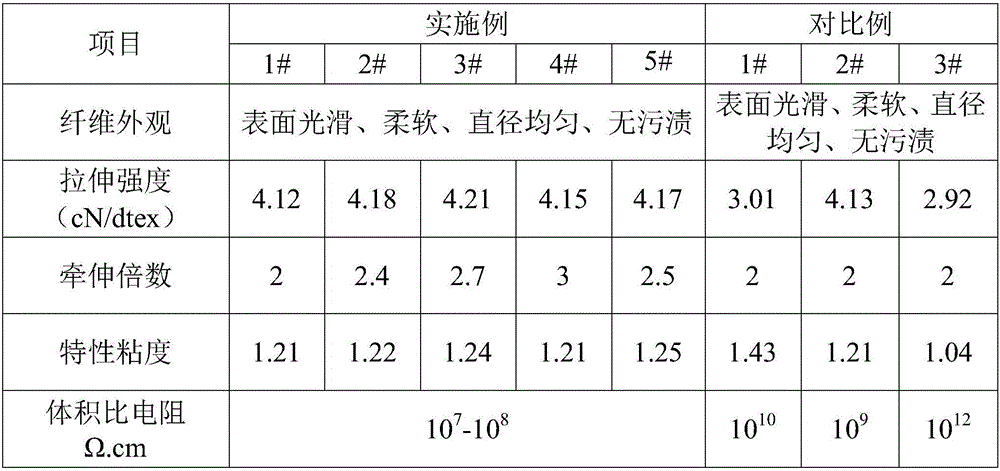

Examples

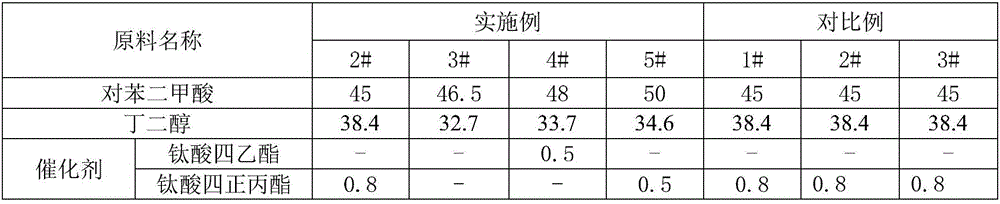

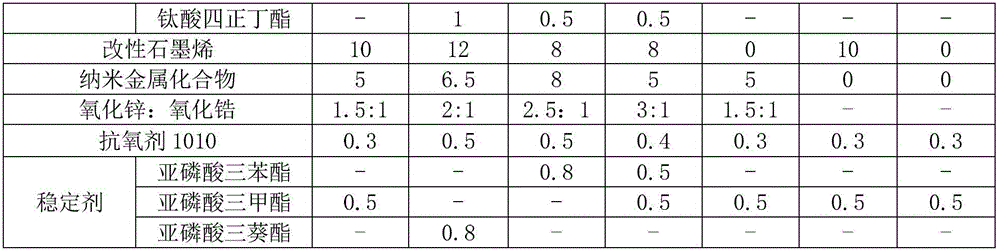

Embodiment 1

[0024] A kind of preparation method of the preparation method of antistatic modified PBT fiber, comprises the steps:

[0025] (1) Adding modified graphene, nano-metal compound and butanediol into the reaction kettle, stirring at a temperature of 50-60°C for 0.5-1h;

[0026] (2) Add terephthalic acid and catalyst into the reaction kettle of step (1), raise the temperature of the system to 200-220°C, and react for 2-3h;

[0027] (3) Add antioxidant 1010 and stabilizer, then vacuumize, raise the temperature to 250-280°C, and perform polycondensation reaction for 3-5h. When the viscosity of the polymer is in the range of 0.6-0.9, the reaction is completed to obtain antistatic modification. Non-toxic PBT polyester;

[0028] (4) Pass the antistatic modified PBT polyester obtained in step (3) through a screw-type spinning machine, carry out melt spinning at a temperature of 250-270°C, and after cooling, carry out oiling, 500-600m / min pre-drawing Stretching and stretching at 1000-18...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com