Pressure control device for whole-process underbalanced drilling and use method

It is an underbalanced drilling and whole-process technology, which is applied in earthwork drilling, wellbore flushing, and wellbore/well components. The effect of simple operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

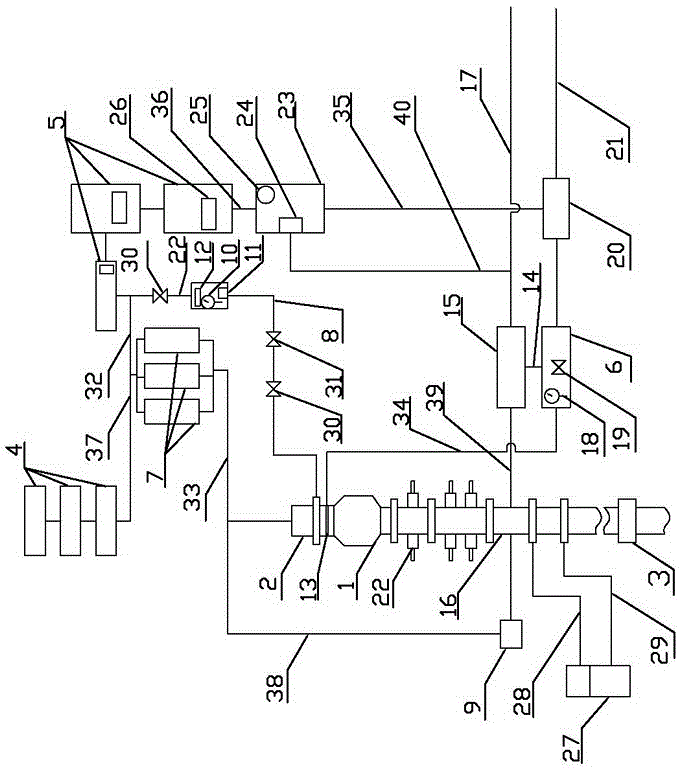

[0026] Embodiment 1: as attached figure 1As shown, the whole-process underbalanced drilling pressure control device includes wellhead blowout preventer group 1, rotary control head 2, downhole casing valve 3, casing string 16, drilling fluid circulation processing device, special choke manifold 6, drilling Pump set 7, drilling fluid continuous injection device for detecting injection pressure and flow rate, and ground control device capable of opening and closing the downhole casing valve 3. The downhole casing valve 3 is fixedly installed on the upper casing string 16, and the outlet of the ground control device It is connected with the downhole casing valve 3 through a pipeline. On the top of the casing string 16 above the downhole casing valve 3, the rotary control head 2 and the wellhead blowout preventer group 1 are fixedly installed in sequence from top to bottom, and the drilling fluid The outlet of the continuous injection device and the grouting port of the rotary con...

Embodiment 2

[0037] Embodiment 2: as figure 1 As shown, a method for using the above-mentioned pressure control device for underbalanced drilling in the whole process includes the following steps:

[0038] The first step is to install the whole-process underbalanced drilling pressure control device before the whole-process underbalanced drilling operation; lower the downhole casing valve 3 together with the upper casing string 16 to an appropriate well depth;

[0039] The second step is to drill according to the routine. When the drill bit is close to the downhole casing valve 3, the wellhead seat seal rotates the control head 2, opens the throttle valve 31 on the special throttle manifold 6, and checks the pressure reading of the second pressure gauge 18 , to ensure that the wellhead back pressure at this time is equal to the wellhead back pressure when tripping under pressure, so that the bottom of the well is always in a relatively stable underbalanced state during tripping; check wheth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com