Accelerator for Automobile Fuel Saving and Environmental Protection

An accelerator and environmental protection technology, applied in the direction of exhaust gas recirculation, machine/engine, engine components, etc., can solve the problems of inability to coordinate control of the throttle valve, complex structure and control system, difficult to install the engine, etc., to protect the normal work, structure and other problems. The effect of simplicity, increased efficiency and power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and examples, but the examples do not constitute a limitation to the present invention.

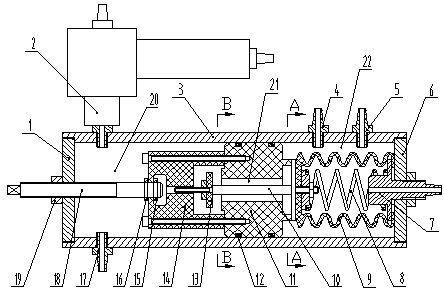

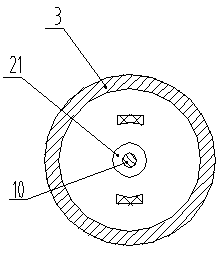

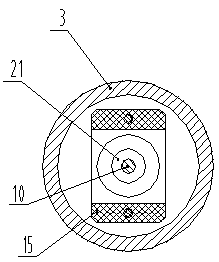

[0017] Figure 1 to Figure 3 The first embodiment of the vehicle fuel-saving and environment-friendly accelerator of the present invention is shown. The vehicle fuel-saving and environment-friendly accelerator includes a cylinder body 3, the two ends of the cylinder body 3 are sealed by end caps 1 and 6, and valves are installed inside the cylinder body 3; The valve includes a valve body 11, a valve core 10, a sealing cover 13, a bellows 9, and a compression spring 8. The valve body 11 is installed on the inner wall of the cylinder body 3, and the valve body 11 and the cylinder body 3 are sealed by a sealing ring 12. , the valve body 11 divides the cylinder body 3 into a compartment I20 and a compartment II22, the valve body 11 is provided with a through hole 21, and the through hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com