Wood pellet multifunctional boiler capable of forced exhaust gas exhaust

A multi-functional, particle-based technology, which can be used in exhaust gas devices, household refrigeration devices, heating methods, etc., can solve problems such as poor operation, achieve beautiful appearance, expand the scope of use, and stabilize heating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Hereinafter, preferred embodiments of the present invention will be described in more detail with reference to the accompanying drawings.

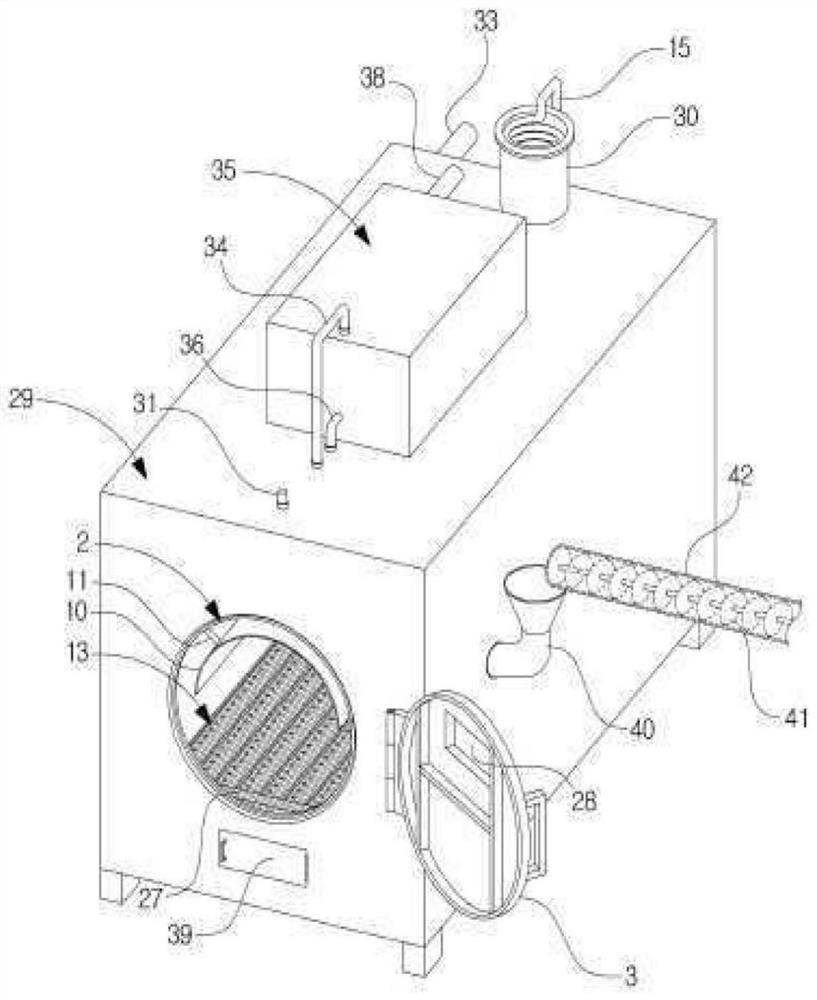

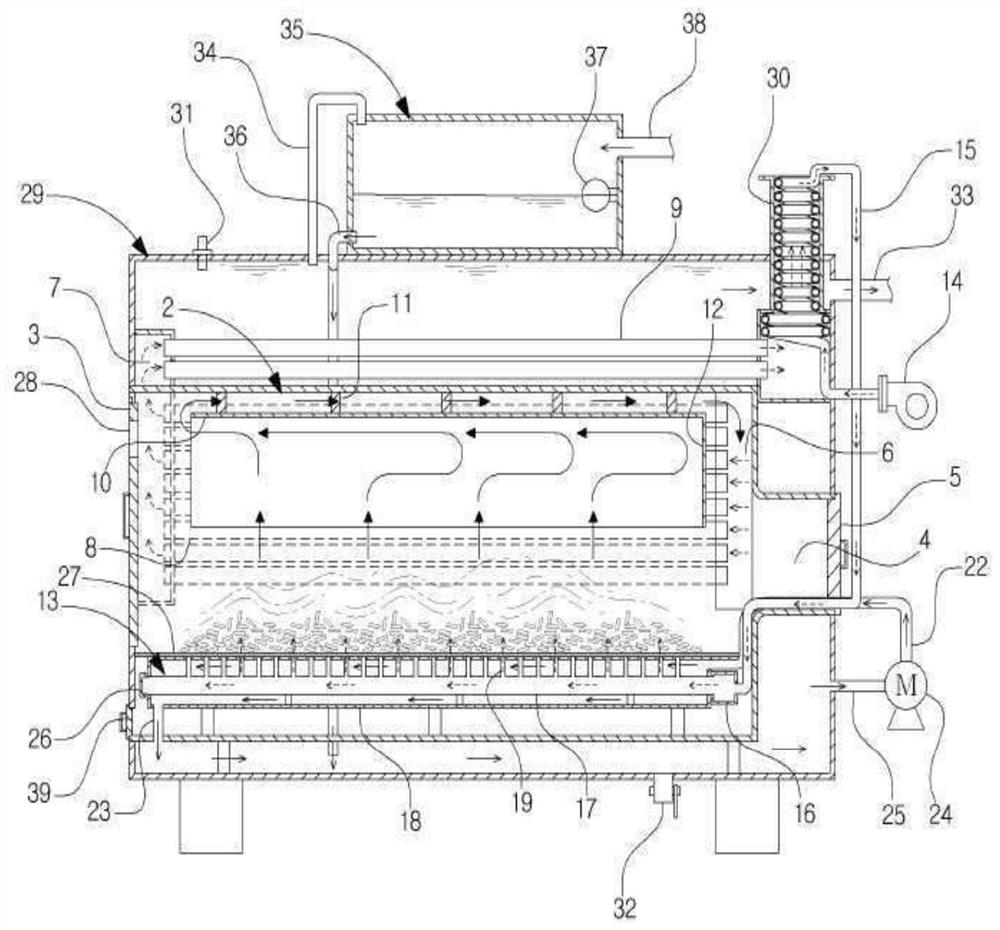

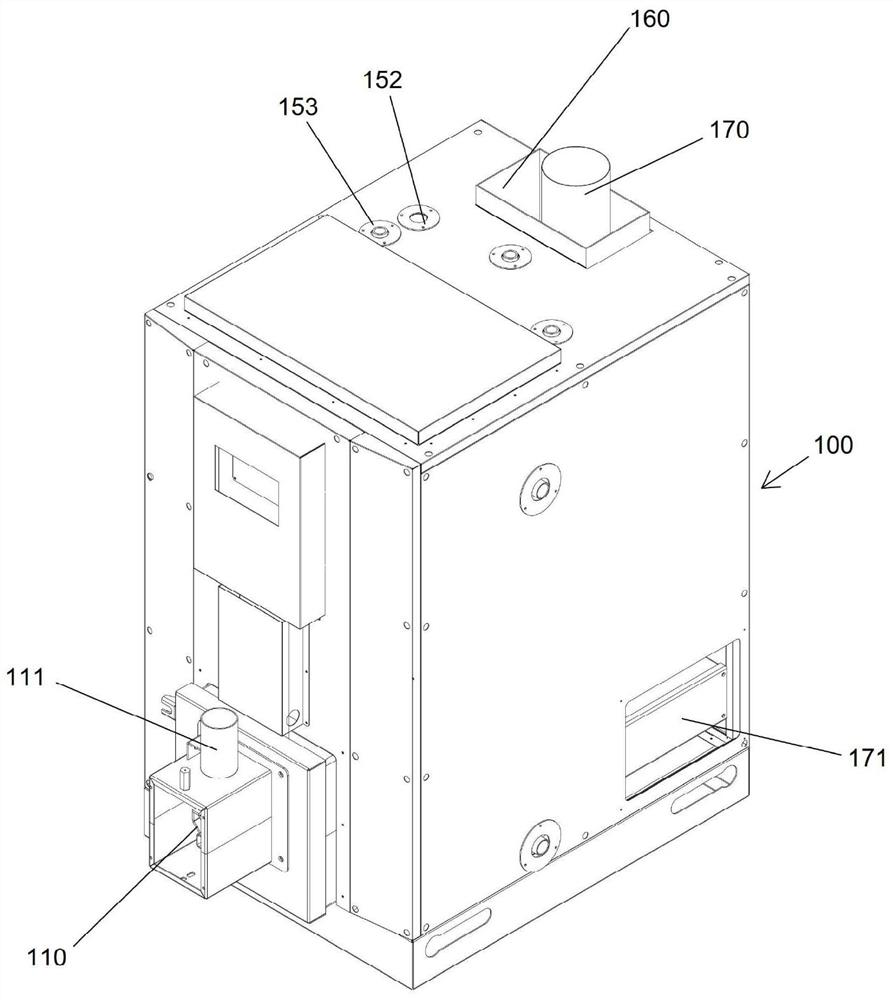

[0041] image 3 It is a perspective view showing the overall structure of the wood pellet multifunctional boiler capable of forcibly exhausting exhaust gas according to the present invention. Figure 4 It is a cross-sectional view showing the internal structure of a wood pellet multifunctional boiler capable of forcibly exhausting exhaust gas according to the present invention. Figure 5It is a partial sectional perspective view showing the internal structure of the wood pellet multifunctional boiler capable of forcibly exhausting exhaust gas according to the present invention. Figure 6 It is a cross-sectional view showing a state where a retaining member is installed on the internal flue pipe of the wood pellet multifunctional boiler capable of forcibly exhausting exhaust gas according to the present invention to retain combustio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com