Cooling system of condenser of intelligent household appliance

A heat dissipation system and condenser technology, applied in evaporators/condensers, resistors with positive temperature coefficients, refrigerators, etc., can solve problems such as poor heat dissipation of condensers, reduce heat generation and reduce energy consumption , the effect of improving the cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

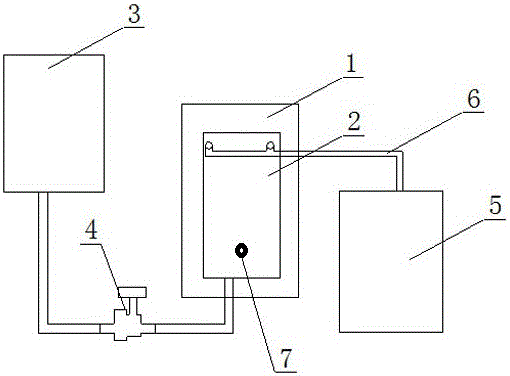

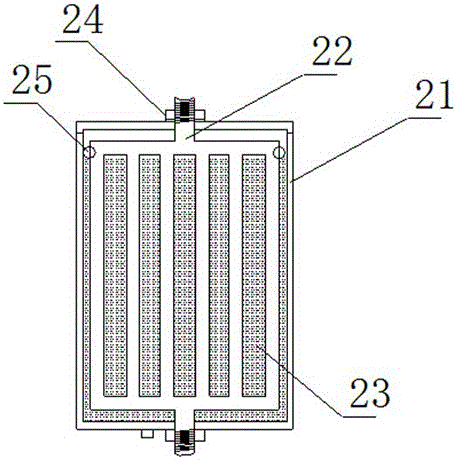

[0032] Such as Figure 1-Figure 2As shown, a heat dissipation system for a condenser of a smart home appliance includes a cooling appliance casing 1 and a condenser 2 vertically installed on the cooling appliance casing 1. The outer heat dissipation shell 21 is composed of a thermistor 7 inside the heat dissipation shell 21. The bottom end of the heat dissipation shell 21 is connected with a water storage tank 3 through a water pipe 6. Between the heat dissipation shell 21 and the water storage tank 3 A temperature-controlled flow control valve 4 is provided on the water pipe, and the temperature-controlled flow control valve 4 is electrically connected with a thermistor 7. The upper end of the heat dissipation housing 21 is connected with a recovery water tank 5 through a water pipe 6.

[0033] The working principle of this embodiment is: the cooling water 23 enters the heat dissipation housing 21 from the water storage tank 3 through the water pipe 6, surrounds the condensin...

Embodiment 2

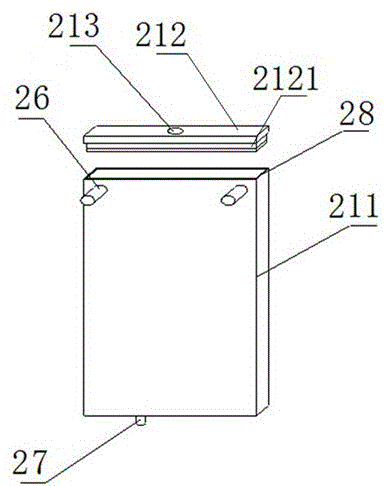

[0036] Such as image 3 As shown, the heat dissipation system of a condenser of a smart home appliance described in Embodiment 1 is further optimized. The heat dissipation housing 21 is composed of an integrated box body 211 with an open top and an upper cover 212. The box body The bottom of the body 211 is provided with a water inlet pipe 27, and the upper end of the box body 211 is provided with at least one level-limiting hole 25 near the opening. 211, the bottom of the box body 211 and the upper cover 212 are provided with mounting holes 213, the central axes of the two mounting holes 213 are on the same vertical line, and the connecting surface of the box body 211 and the upper cover 212 is provided with a sealing Ring 28, the two ends of the condensing device 22 protrude out of the heat dissipation housing 21 through the installation hole 213, and the two ends of the condensing device 22 are sleeved with fasteners for fixing the box body 211 and the upper cover 212.

[...

Embodiment 3

[0042] On the basis of the heat dissipation system of the condenser of a smart home appliance described in Embodiment 2, it is further optimized. The lower end of the upper cover 212 is provided with a limiting plate 2121. When this embodiment is installed, the limiting plate 2121 extends into the box. Inside the body 211, the upper cover 212 can be aligned with the box body 211 to avoid the deviation of the box body 211 and the upper cover 212 during the installation process, thereby avoiding the deviation caused by the box body 211 and the upper cover 212 during the installation process. The problem of poor sealing performance caused.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com