Method for detecting dynamic material level in fluidized bed

A detection method and fluidized bed technology, applied in the direction of liquid level indicators for physical variable measurement, etc., can solve the problems of high price, complex measurement system, limited application range of temperature measurement method and capacitance method, etc., to achieve accurate results and improve The effect of fluidized bed production and product quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

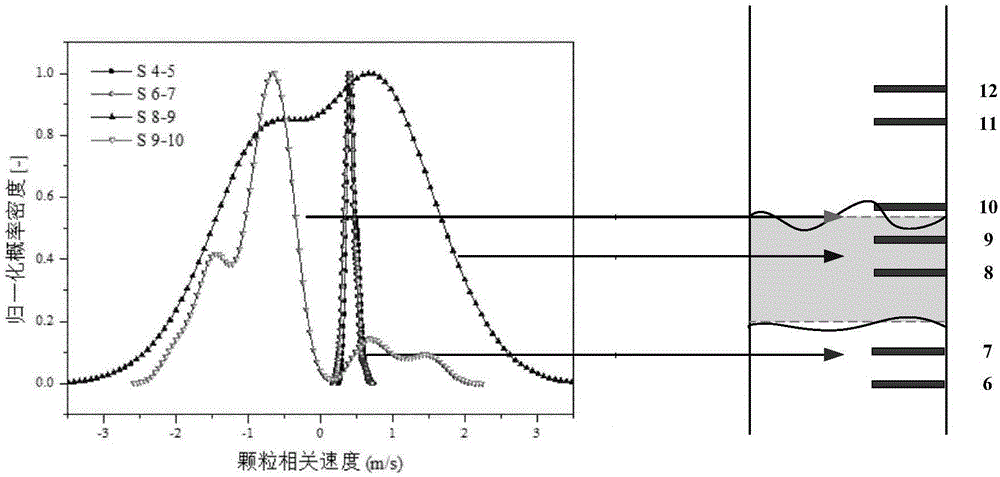

[0026] Experiments were carried out using a plexiglass fluidized bed cold model experimental device, and the schematic diagram of the device is shown in figure 1 As shown, it is composed of a fluidization system and a detection system, 1 is a computer, 2 is a data acquisition card, 3 is a fan, 4 is a dryer, 5 is a flow meter, and 6 is an air inlet valve. The fluidized particles are LLDPE particles. The physical parameters of the particles are shown in Table 1. They belong to the Geldart B type particles. The initial fluidization velocity (u mf ) is 0.2m / s. The relative humidity of the fluidization gas is 8-15%, and the experiment is carried out at room temperature. Under the superficial gas velocity (u) involved in the experiment, the fluidized bed is always in a bubbling fluidized state. Table 2 shows the material weight and experimental gas velocity range of the particles.

[0027] Table 1 Some physical parameters of LLDPE particles

[0028]

[0029] Table 2 B type fl...

Embodiment 2

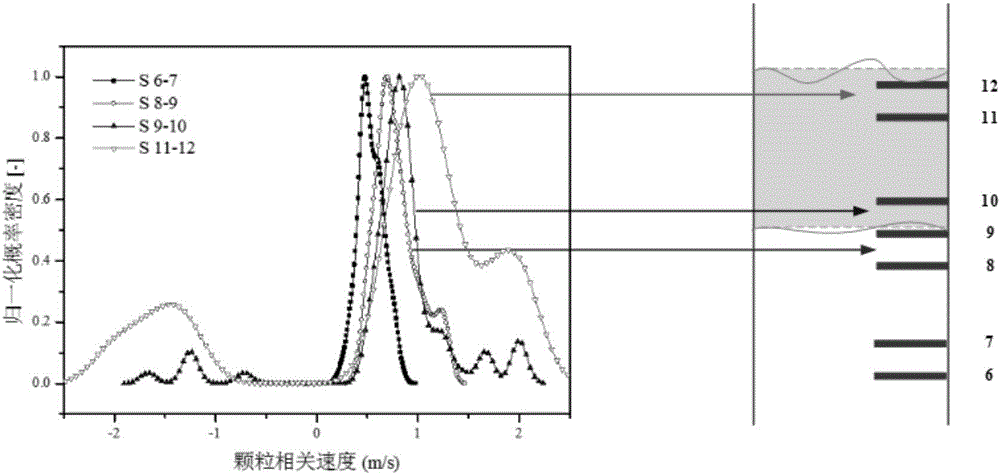

[0046] The fluidized bed in Example 1 is replaced by a plexiglass fluidized bed with a diameter of 420mm, and the material weight of the LLDPE particles is increased to 13.5g to ensure that the static bed height remains consistent with that of Example 1. The electrode arrangement is as Figure 7 As shown, using an annular induction electrode array matched with the fluidized bed, the wide width of the induction electrode is 40mm, the arrangement of the electrode array is consistent with that of Example 1, the sampling frequency is increased to 6000Hz, and the superficial gas velocity is increased to 0.7m / s.

[0047] Collect data for experiments:

[0048] 1) Sweep the plexiglass fluidized bed with dry air for 10 minutes, then add 13.5 kg of pre-dried LLDPE particles, and the static bed height is 265 mm.

[0049] 2) Fluidize the particles for 30 minutes at a certain superficial gas velocity to ensure that the particles are fully charged and saturated. At the same time, the el...

Embodiment 3

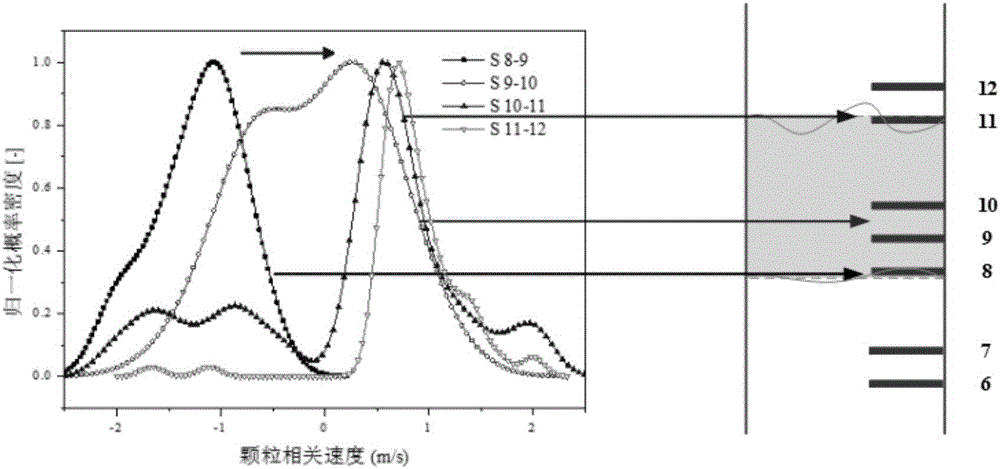

[0054] The experimental device and experimental method are the same as in Example 1. The fluidized particles are replaced by PP particles. The physical parameters of the particles are shown in Table 3. They belong to the Geldart D type particles. The initial fluidization velocity (u mf ) is 0.5m / s, and the material weight and experimental gas velocity range of the particles are shown in Table 4.

[0055] Table 3 Some physical parameters of PP particles

[0056]

[0057] Table 4 PP pellet weight and experimental gas velocity

[0058]

[0059] The signal acquisition method and data processing method are all the same as in Example 1, and the normalized probability density distribution of the relative velocity of the particle group at different positions is obtained as follows: Figure 9 .

[0060] Combined with the specific position of the electrode, it is speculated that at this gas velocity, the fluctuation range of the dynamic material level is 380-580mm, and the aver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com