Test method based on assembly line constant temperature and humidity room

A constant temperature and humidity test, constant temperature and humidity technology, applied in the direction of environmental/reliability testing, measuring electricity, measuring devices, etc., can solve problems such as unfavorable production testing, potential safety hazards, and labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

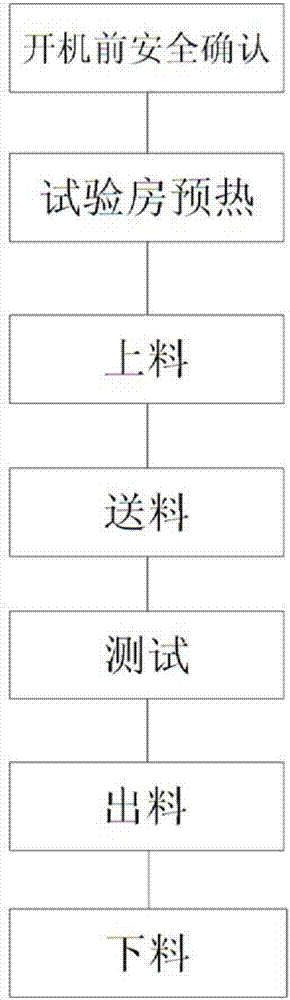

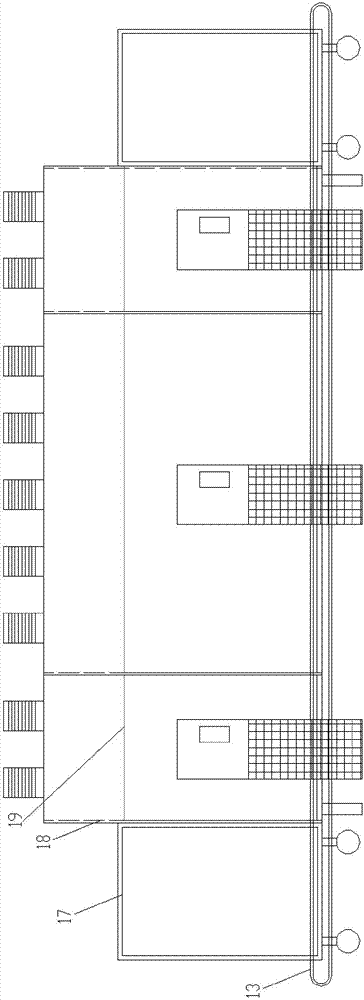

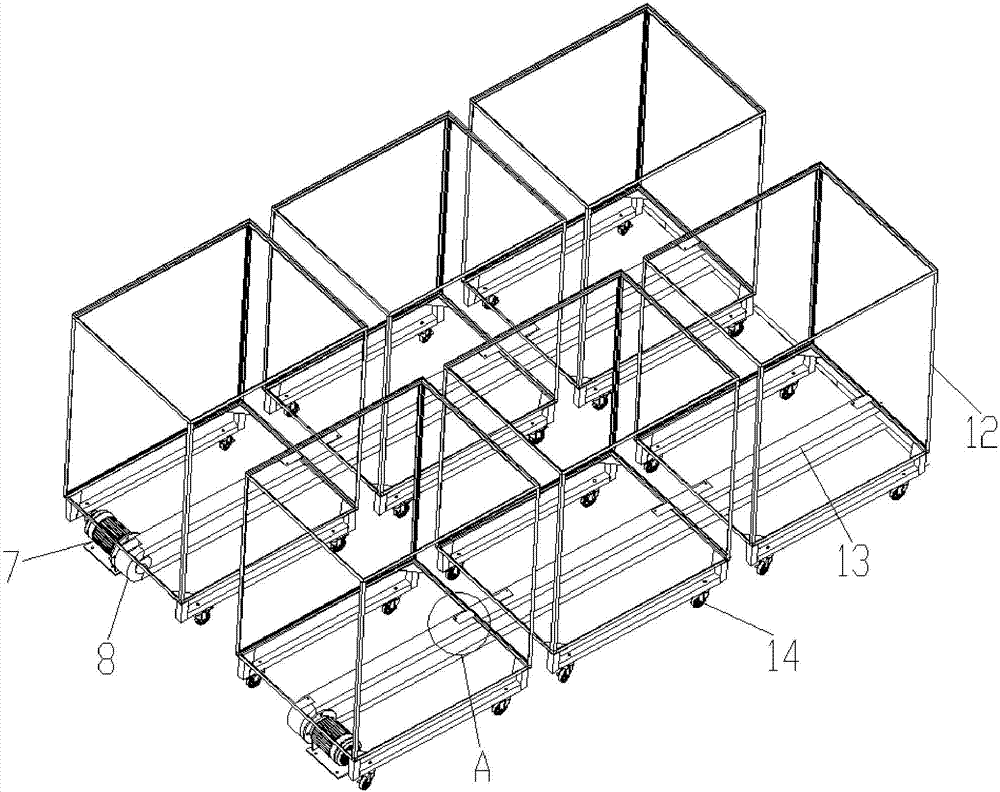

[0044] Such as Figure 1~5 As shown, it shows the specific implementation of the present invention, as shown in the figure, the present invention is based on the test method of the assembly line type constant temperature and humidity room, including the following steps:

[0045] (1) Safety confirmation before starting the machine;

[0046] (2) Preheat the test room; close the access door, open the air-conditioning system in the assembly line constant temperature and humidity room to preheat; preset the temperature and humidity, time, and power action procedures according to the test requirements.

[0047] (3) Loading: put the product to be tested into the layer rack of the assembly line constant temperature and humidity room, and push it into the conveyor belt for fixing;

[0048] (4) Feeding; open the entrance door to form a feeding channel, and start the air curtain to prevent the loss of temperature and humidity in the test room; start the power component of the assembly l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com