Double-station exposure method

An exposure method and a double-station technology, which are applied in photolithography exposure devices, microlithography exposure equipment, optics, etc., can solve problems affecting production line production efficiency, and achieve the effect of improving production efficiency and simple operation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

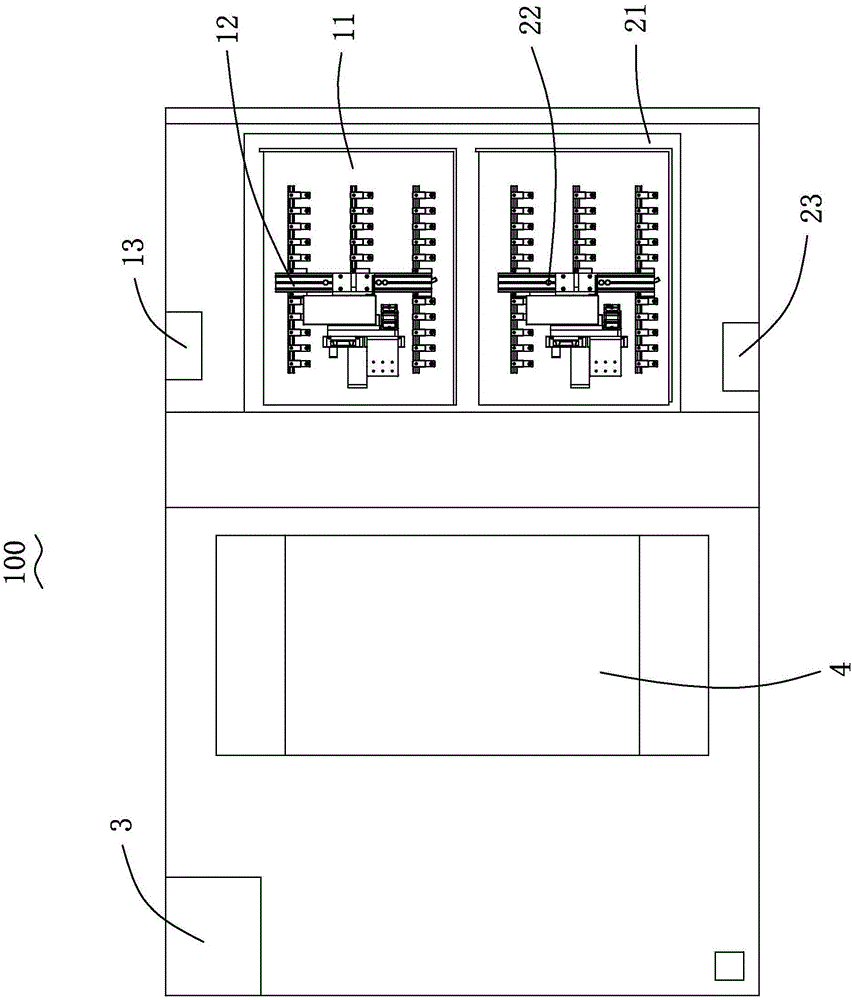

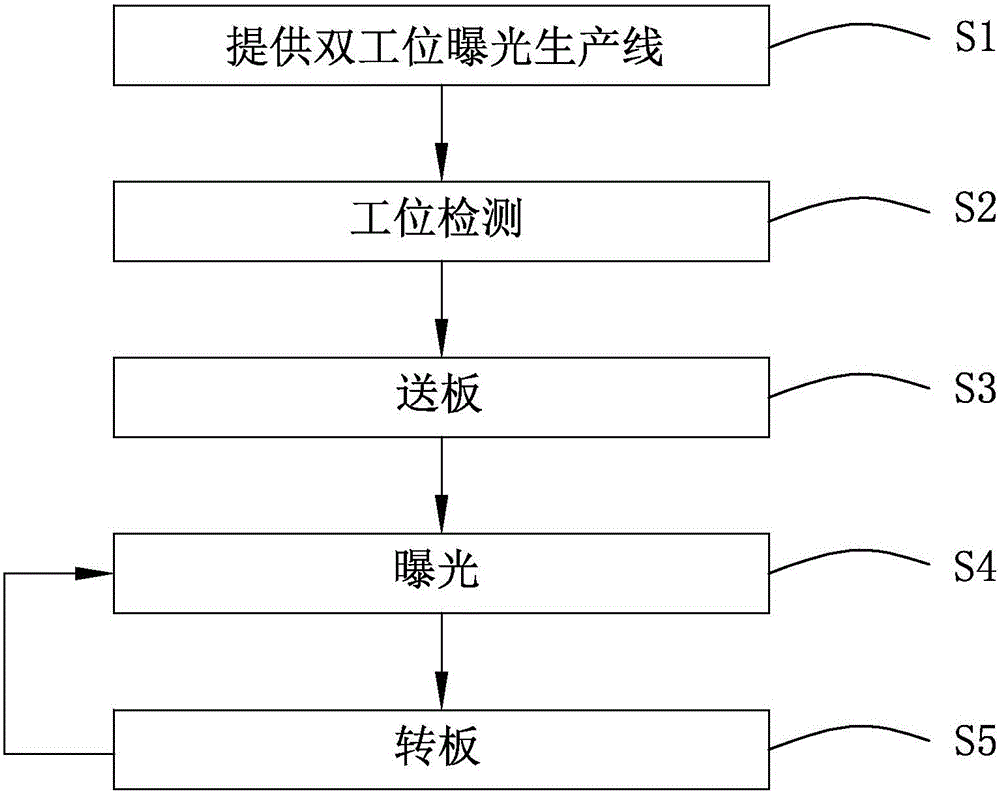

[0024] Please also see figure 1 and figure 2 ,in, figure 1 It is a partial structural schematic diagram of the double-station exposure production line provided in the double-station exposure method of the present invention; figure 2 It is a flow chart of the dual-station exposure method of the present invention. The invention provides a double-station exposure method, comprising the following steps:

[0025] Step S1, providing a double-station exposure production line 100, including:

[0026] The first station 11 and the second station 21 for realizing the exposure process;

[0027] The first suction cup 12 and the second suction cup 22 cooperating with the first station 11 and the second station 21, the first station 11 and the second station 21 are exposed along the double station The flow direction of the production line 100 is arranged side ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap