A kind of aluminum alloy for cable and its preparation method and application

An aluminum alloy and cable technology, which is applied in the manufacture of cables/conductors, coaxial cables, metal/alloy conductors, etc., can solve the problems of high tensile strength requirements of inner conductors, increased use costs, and insufficient cable tensile strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

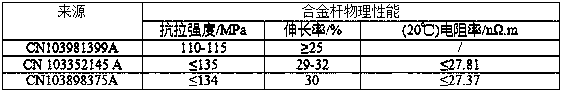

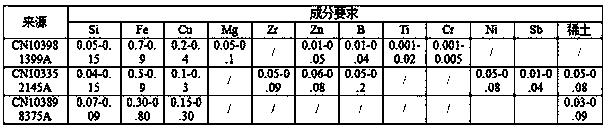

Method used

Image

Examples

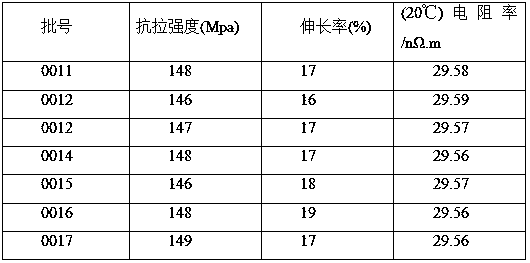

Embodiment 1

[0026] After entering 20 tons of aluminum, add 76kg of AlCu50 master alloy and 314kg of 75% iron agent, stir for 20 minutes, control the temperature to 730°C for refining, the amount of refining agent is 6‰, and the time is 35 minutes. After refining, remove the surface slag Clean, let stand for 25 minutes to sample. Casting begins when the composition of the alloy liquid meets the requirements and the temperature is 730°C; after opening the furnace hole, feed the Al-Ti-B rod at the position before the aluminum liquid enters the online degassing equipment, and the feeding speed is 0.9m / min; the aluminum liquid undergoes on-line refining and The filter equipment is used for degassing and slag removal. After testing, the degassing efficiency of online refining is 52%, and the filter specification is 50ppi; the casting temperature is guaranteed to be 675-690°C during the entire casting process; 530°C, finally produce an aluminum alloy rod with a diameter of about 9.5mm (Si≤0.10%,...

Embodiment 2

[0029] Enter 20 tons of aluminum, then add 68kg of AlCu50 master alloy, 258kg of 75% iron, stir for 20 minutes, control the temperature to 723°C for refining, the amount of refining agent is 5‰, and the time is 32 minutes. After refining, remove the surface slag Clean, let stand for 20 minutes to sample. Casting begins when the composition of the alloy liquid meets the requirements and the temperature is 735°C; after opening the furnace hole, feed the Al-Ti-B rod at the position before the aluminum liquid enters the online degassing equipment, and the feeding speed is 1.2m / min; the aluminum liquid is refined on-line and The filter equipment is used for degassing and slag removal. After testing, the degassing efficiency of online refining is 50%, and the filter specification is 50ppi; the casting temperature is guaranteed to be 680-695°C during the entire casting process; 530°C, finally produce an aluminum alloy rod with a diameter of about 9.5mm (Si≤0.10%, Ti≤0.03%, individual...

Embodiment 3

[0032] Enter 20 tons of aluminum, then add 96kg of AlCu50 master alloy, 342kg of 75% iron, stir for 30 minutes, control the temperature to 735°C for refining, the amount of refining agent is 8‰, and the time is 45 minutes. After refining, the surface slag is removed Clean, let stand for 30 minutes to sample. Casting begins when the composition of the alloy liquid meets the requirements and the temperature is 741°C; after opening the furnace hole, feed the Al-Ti-B rod at the position before the liquid aluminum enters the on-line degassing equipment, and the feeding speed is 0.5m / min; The filter equipment is used for degassing and slag removal. After testing, the degassing efficiency of online refining is 50%, and the filter specification is 50ppi; the casting temperature is guaranteed to be 685-700°C during the entire casting process; 535°C, finally produce an aluminum alloy rod with a diameter of about 9.5mm (Si≤0.10%, Ti≤0.03%, individual impurity elements≤0.01%, total impuri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com