Permanent magnetic vernier motor

A vernier motor and permanent magnet technology, applied in the direction of magnetic circuits, electromechanical devices, electrical components, etc., can solve the problems of low motor space utilization, low motor material utilization, low torque density, etc., to improve space utilization and , enhance the reliability and fault-tolerant operation of the system, and improve the effect of torque and power level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

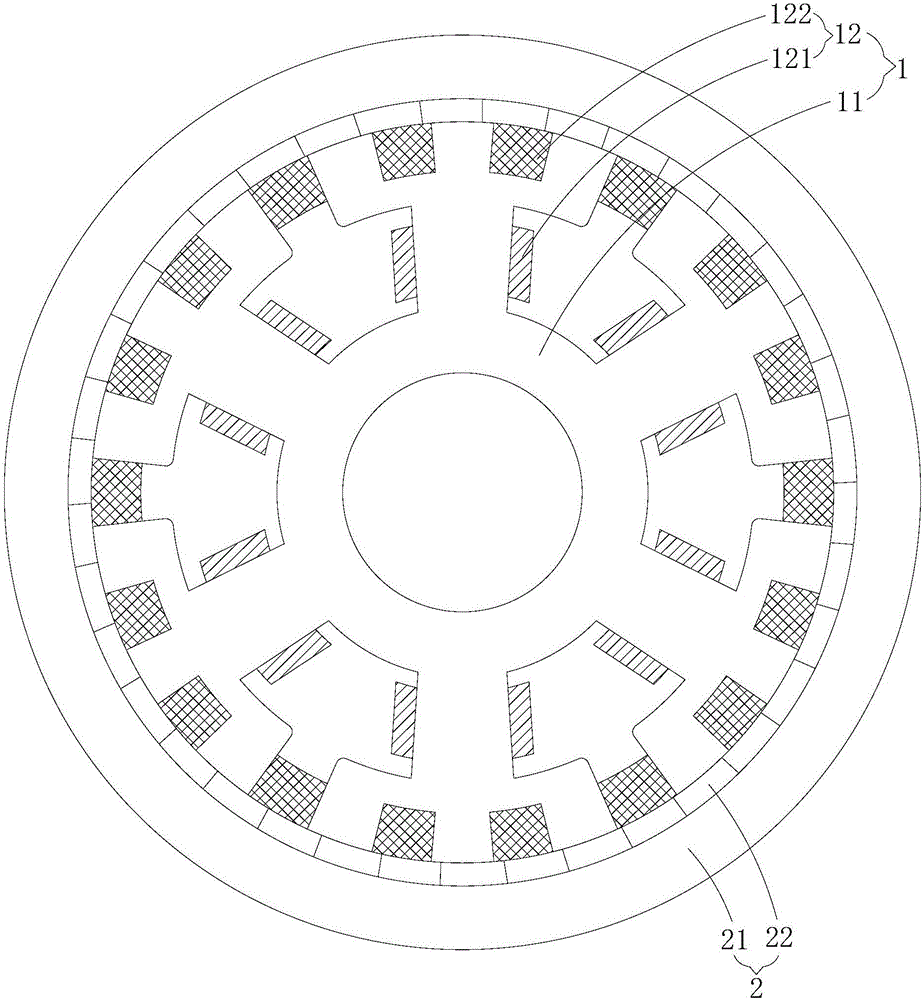

[0030] Such as Figure 1-4 As shown, the permanent magnet vernier motor provided by Embodiment 1 of the present invention includes a stator 1 and a rotor 2 that rotates with the stator 1. The stator 1 includes a stator core 11 and a stator winding 12 arranged on the stator core 11. The rotor 2 Including the rotor core 21 and the permanent magnet 22 arranged on the rotor core 21, the stator winding 12 includes a first set of windings 121 and a second set of windings 122, the first set of windings 121 and the second set of windings 122 operate independently of each other, and The number of pole pairs of the first set of windings 121 is greater or smaller than the number of pole pairs of the second set of windings 122 , that is, the number of pole pairs of the first set of windings 121 and the number of pole pairs of the second set of windings 122 are not equal. Both the first set of windings 121 and the second set of windings 122 can be single-phase windings or multi-phase windi...

Embodiment 2

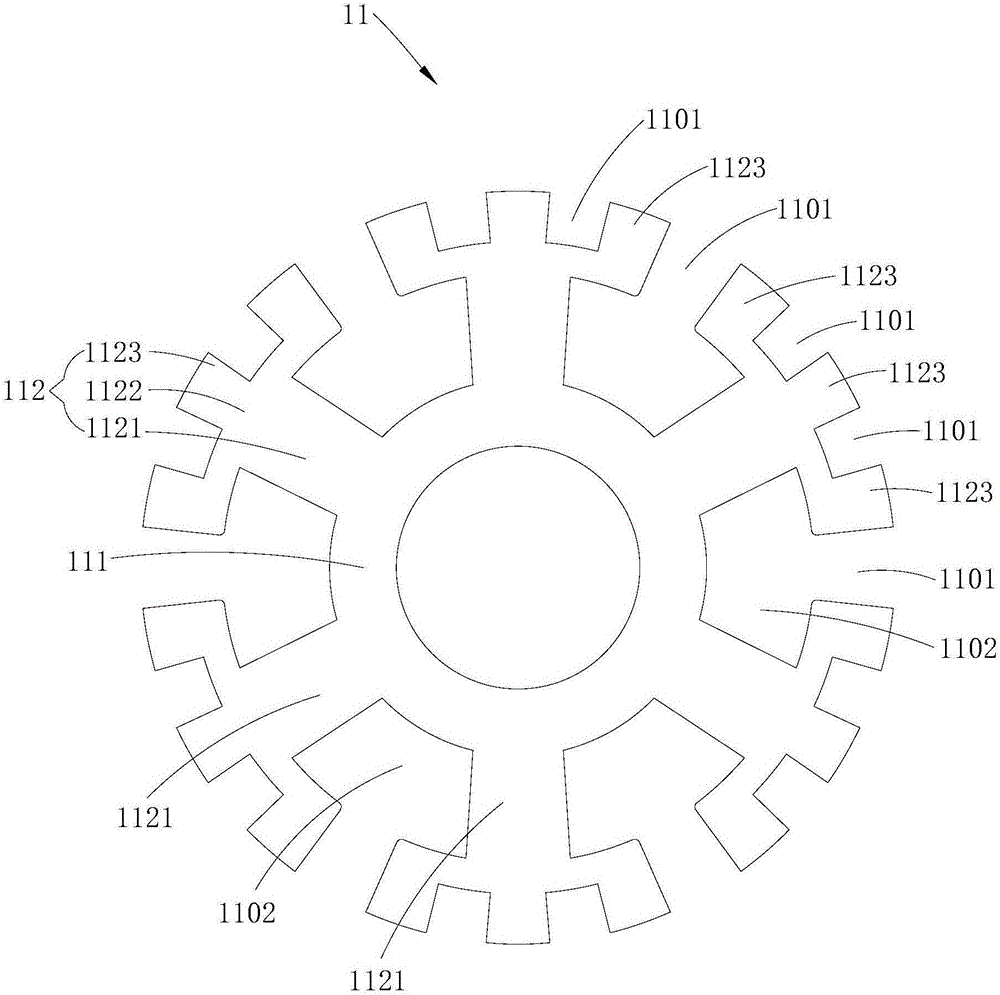

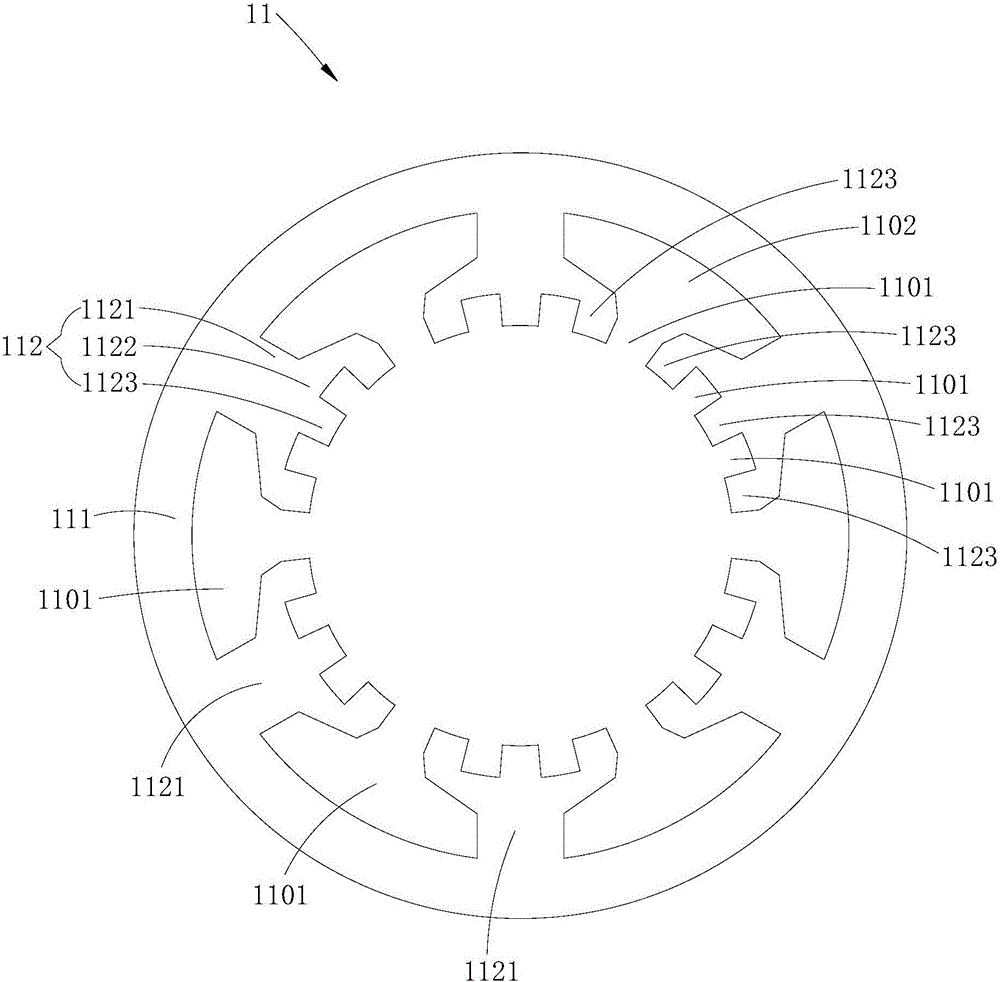

[0043] Such as Figure 5 and Figure 6 As shown, the main difference between the permanent magnet vernier motor provided in this embodiment and the first embodiment is that the stator 1 in the first embodiment is a split-pole stator structure, and the first set of windings 121 and the second set of windings 122 are along the The stator core 11 is radially distributed inside and outside; while the stator 1 in this embodiment is an open slot stator structure, specifically, the stator core 11 in this embodiment includes a stator yoke 111 and several circumferentially spaced The protruding teeth 113 on the stator yoke 111, the stator yoke 111 is a circumferentially closed ring structure, the protruding teeth 113 are protruded on the inner or outer side of the stator yoke 111, and a notch is formed between any two adjacent protruding teeth 113 1101 , the first set of windings 121 and the second set of windings 122 are distributed in each slot 1101 . In this embodiment, the first ...

Embodiment 3

[0047] Such as Figure 7 As shown, the main difference between the permanent magnet vernier motor provided in this embodiment and the first and second embodiments is that the installation methods of the first magnet 221 and the second magnet 222 are different. Specifically, in Embodiment 1 and Embodiment 2, each first magnet 221 and each second magnet 222 are attached and fixed on the surface of the rotor core 21, and each first magnet 221 and each second magnet 222 are exposed on the The surface of the rotor core 21; and in the present embodiment, each first magnet 221 and each second magnet 222 are inserted and fixed in the rotor core 21, and the surface of the rotor core 21 is provided with several magnets for each first magnet respectively. The magnets 221 and the second magnets 222 are inserted into the fixed installation slots, and only one surface of each first magnet 221 and each second magnet 222 is flush with the surface of the rotor core 21 . Specifically, when the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com