Double-rowed universal wheel

An omnidirectional wheel and hub technology, applied in the direction of wheels, transportation and packaging, vehicle parts, etc., can solve the problems of large contact impact, traces on the ground, large noise and bumps, etc., to improve rolling performance, reduce noise, reduce The effect of the thrashing problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

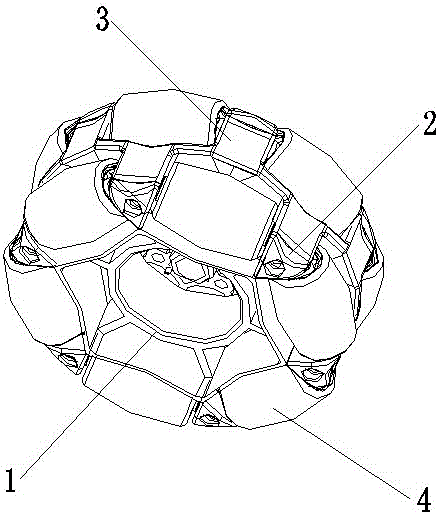

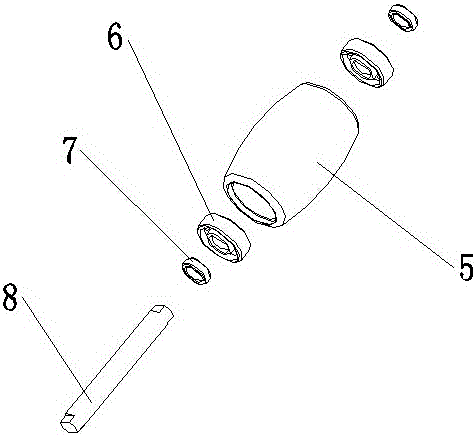

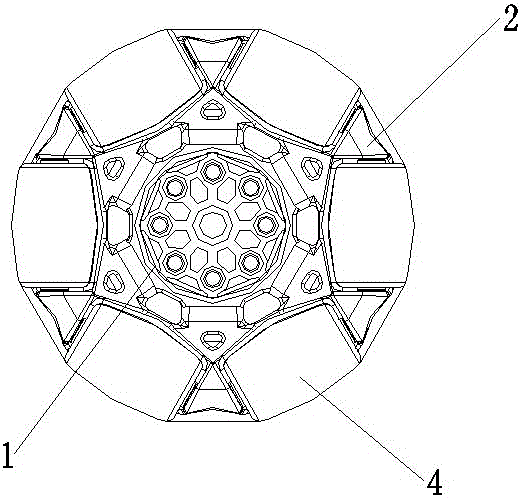

[0022] See figure 1 , figure 2 , image 3 , Figure 4 , A double-row omnidirectional wheel of the present invention is composed of a hub 1, an omnidirectional wheel fixing block B, an omnidirectional wheel fixing block A, and an omnidirectional wheel roller assembly 4, wherein the omnidirectional wheel roller assembly 4 includes a small roller 5. Two small roller bearings 6, two spacer blocks 7 and omnidirectional wheel pins 8. The small roller 5 is composed of external soft rubber wrapped with internal hard rubber. The rim of the small roller 5 is curved, and the two small roller bearings 6 Located on the inner sides of the two ends of the small roller 5, the small roller bearing 6 is composed of an inner ring and an outer ring. The inner ring is sleeved on the omnidirectional wheel pin 8, and the outer ring is clamped with the hard...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com