Process for producing anhydrous ammonia by ammonia distillation and deacidification

An anhydrous ammonia and deacidification technology, applied in the field of coal chemical industry, can solve the problems of low ammonia content, failure to meet environmental protection requirements, and low purity of ammonia vapor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

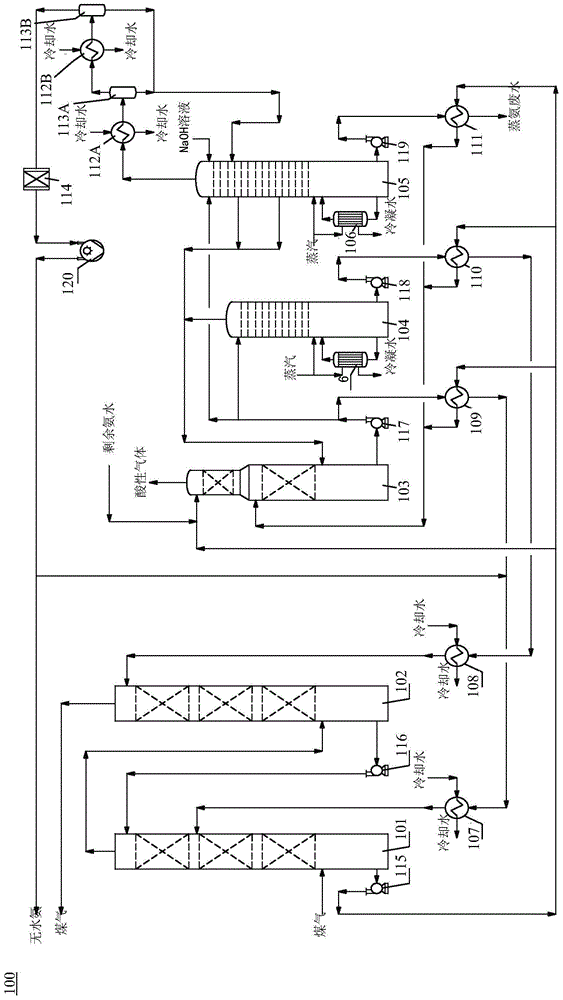

[0063] Such as figure 1 Shown, containing hydrogen sulfide 1-12g / m 3 , containing ammonia 2-13g / m 3 The coal gas enters the hydrogen sulfide scrubber 101 and the ammonia scrubber 102 in turn, absorbs hydrogen sulfide with desulfurized barren liquid and rich ammonia water, and absorbs ammonia with stripped water. Both the hydrogen sulfide scrubber and the ammonia scrubber operate under normal pressure, and the scrubbing temperature is 22-24°C. The hydrogen sulfide content of the washed gas is 200mg / m 3 Below, the ammonia content is 100mg / m 3 the following. The ammonia-rich water at the bottom of the ammonia scrubber is sent to the top of the hydrogen sulfide scrubber as part of the absorption liquid by the ammonia water pump 116 for spraying; the desulfurization-rich liquid at the bottom of the hydrogen sulfide scrubber mainly contains ammonia, fixed ammonium salts, hydrogen sulfide, hydrogen cyanide, and carbon dioxide , water, organic hydrocarbons and other components ar...

Embodiment 1

[0084] Embodiment 1 (in conjunction with attached figure 1 )

[0085] Such as figure 1 Shown, containing hydrogen sulfide 6g / m 3 , containing ammonia 8g / m 3 The coal gas enters the hydrogen sulfide scrubber 101 and the ammonia scrubber 102 in turn, absorbs hydrogen sulfide with desulfurized barren liquid and rich ammonia water, and absorbs ammonia with stripped water. Both the hydrogen sulfide scrubber and the ammonia scrubber operate under normal pressure, and the scrubbing temperature is 22-24°C. The hydrogen sulfide content of the washed gas is 200mg / m 3 Below, the ammonia content is 100mg / m 3 the following. The ammonia-rich water at the bottom of the ammonia scrubber is sent to the top of the hydrogen sulfide scrubber as part of the absorption liquid by the ammonia water pump 116 for spraying; the desulfurization-rich liquid at the bottom of the hydrogen sulfide scrubber mainly contains ammonia, fixed ammonium salts, hydrogen sulfide, hydrogen cyanide, and carbon dio...

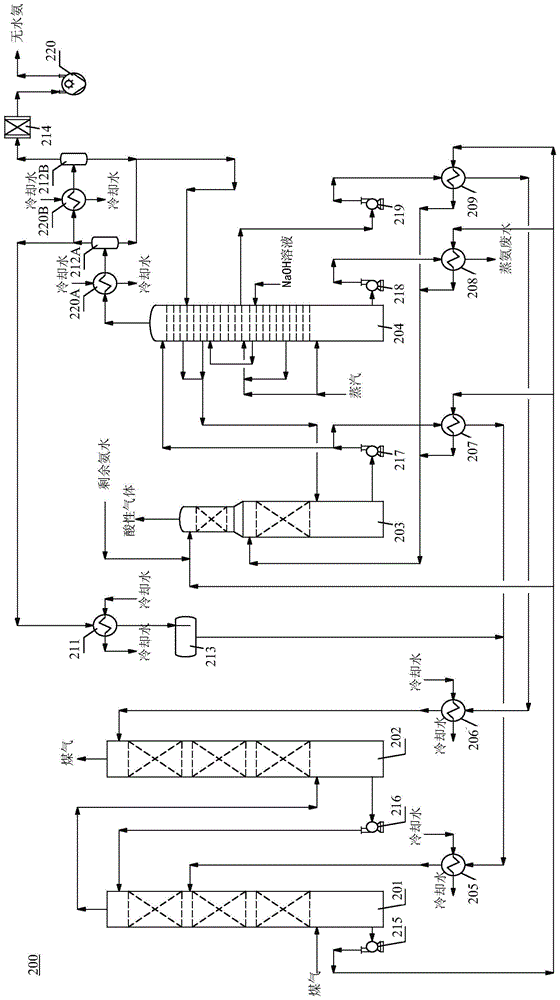

Embodiment 2

[0092] Embodiment 2 (in conjunction with attached figure 2 )

[0093] Such as figure 2 Shown, containing hydrogen sulfide 8g / m 3 , containing ammonia 8g / m 3 The coal gas enters the hydrogen sulfide scrubber 201 and the ammonia scrubber 202 in sequence, absorbs hydrogen sulfide with desulfurized barren liquid and rich ammonia water, and absorbs ammonia with stripped water. Both the hydrogen sulfide scrubber and the ammonia scrubber operate under normal pressure, and the scrubbing temperature is 22-24°C. The hydrogen sulfide content of the washed gas is 200mg / m 3 Below, the ammonia content is 100mg / m 3 the following. The ammonia-rich water at the bottom of the ammonia washing tower is sent to the top of the hydrogen sulfide washing tower as part of the absorption liquid by the ammonia water pump 216 for spraying; the desulfurization-rich liquid at the bottom of the hydrogen sulfide washing tower mainly contains ammonia, fixed ammonium salts, hydrogen sulfide, hydrogen cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com