Elevation-type micro-power MBR apparatus

A technology of power and height, applied in the field of high-level micro-power MBR devices, can solve the problems of energy saving and emission reduction, high operating costs, etc., and achieve the effects of high degree of automation, reduced investment, and reduced operating energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

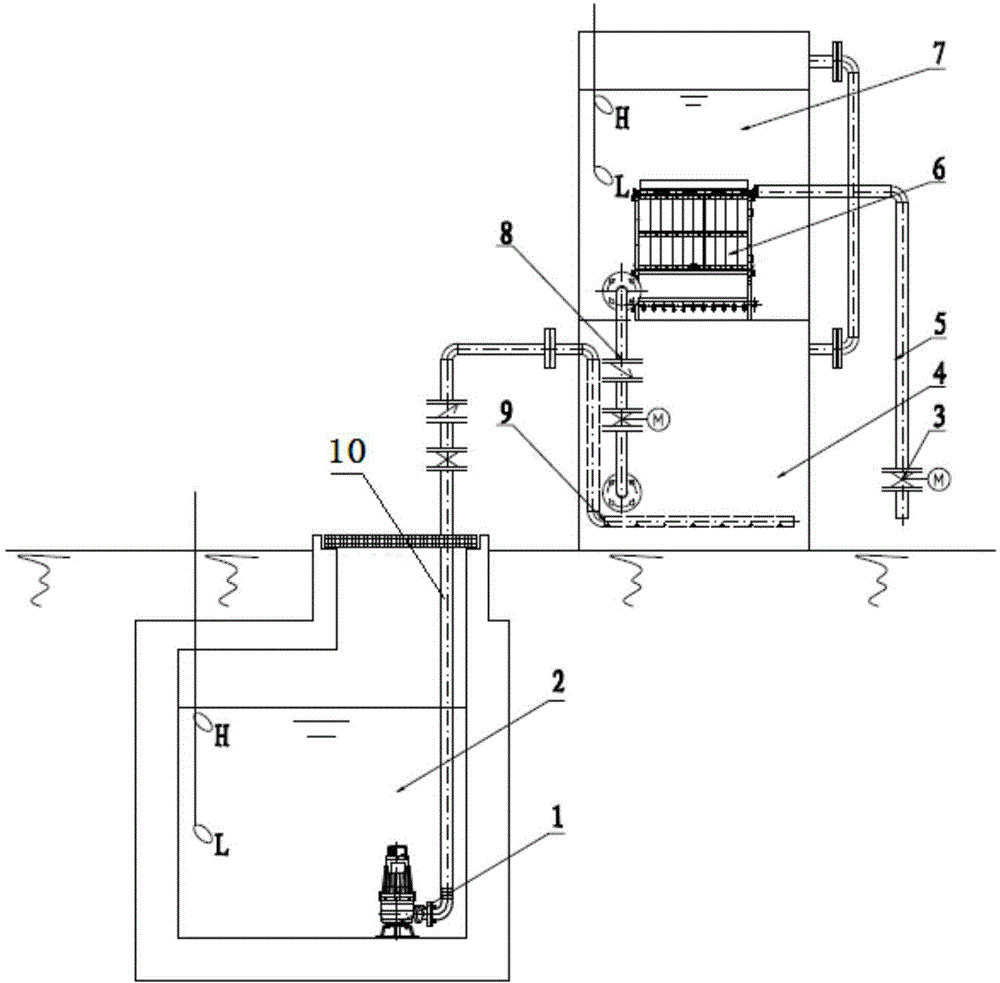

[0007] figure 1 As shown, it involves a high-level micro-power MBR device, including a sump 2, and a sewage lift pump 1 located at the bottom of the sump 2, the output of the sewage lift pump 1 is connected to the anoxic pool through a sewage pipeline 10 4 and evenly distribute water through the perforated pipe 9 horizontally arranged at the bottom of the anoxic pool 4; Membrane module 6, the upper part of the MBR flat membrane module 6 is connected to the external membrane outlet electric valve 3 through the membrane module outlet pipe 5, and the lower part is extended to the anoxic pool 4 through the nitrifying liquid return device 8 bottom.

[0008] The working process is as follows: in this equipment, the sewage is lifted to the anoxic pool 4 through the sewage lifting pump 1 arranged in the sump 2, and after the bottom of the anoxic pool 4 is evenly distributed through the perforated pipe 9, the waste water of the sewage lifting pump 1 is continued to be used. The press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com