Chain belt type automatic lifting floating wharf

An automatic lifting and floating dock technology, applied in the field of floating docks, can solve the problems of difficult operation, heavy channel steel, inconvenient hoisting and installation, etc., and achieve the effect of flexible lifting and sliding, low manufacturing cost and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

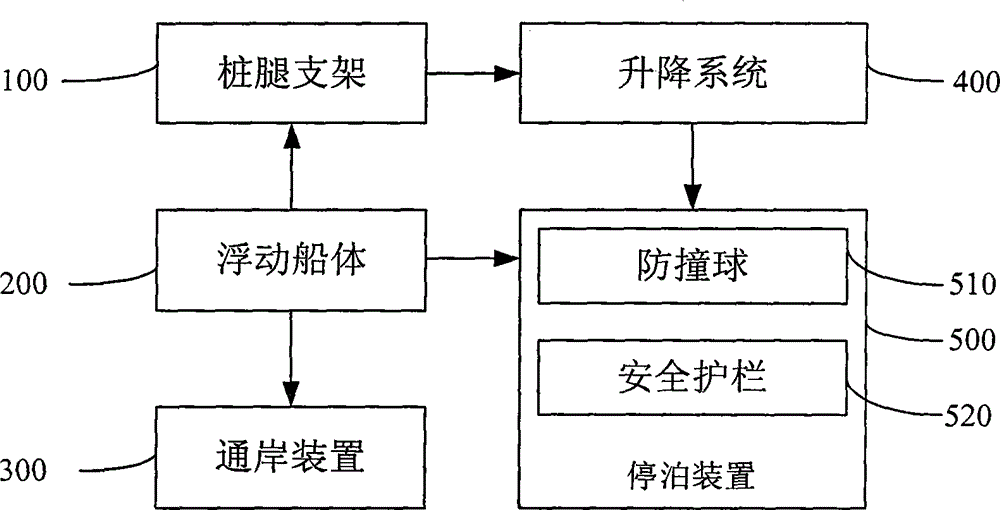

[0021] like figure 1 As shown, a chain-belt type automatic lifting floating dock includes: a floating hull, a leg support, a lifting system, a shore access device and a mooring device;

[0022] The floating hull is provided with a special crane, which is fixed on the seabed;

[0023] The parking device also includes anti-collision balls and safety guardrails;

[0024] The bank access device is also provided with a winch for balancing the lifting speed of the lifting system;

[0025] The leg support is fixed on the seabed, and is also equipped with a pile-inserting hydraulic cylinder for lifting;

[0026] The lifting system is connected with the shore access device.

[0027] In the chain-belt type automatic lifti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com