Oil extraction method for steam assisted gravity drainage (SAGD) dual horizontal well and tubular column equipment of oil extraction method

A technology of double horizontal wells and pipe strings, which is applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc. It can solve the problems of complex lifting process conditions and limited use of equipment, and achieve the solution of lifting process work. Complex conditions, simple working conditions, and small equipment restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

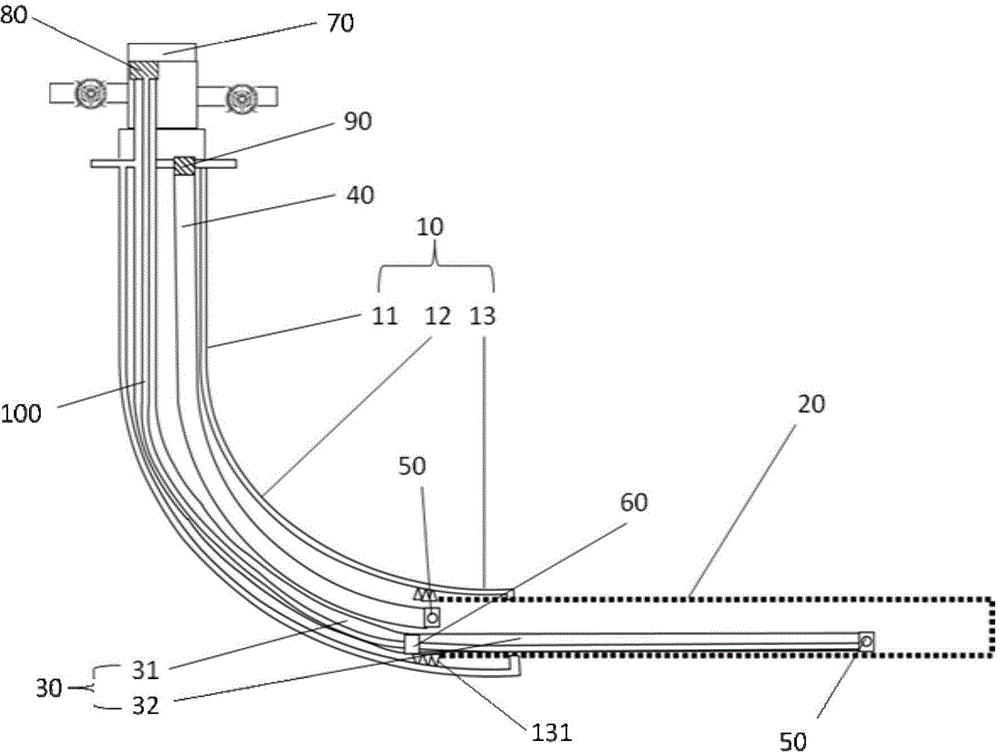

[0025] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0026] In the prior art, for the lifting process of SAGD oil production technology, especially for shallow oil production, it is necessary to take out all the string equipment in the production well and replace a large number of pumping equipment when transferring from the cycle preheating stage to the production stage . Moreover, due to the particularity of shallow oil exploitation and the geological conditions of our country, oil pumping equipment such as electric submersible pumps, rod pumps, etc., all have the problem of not being able to work stably for a long time, and the equipment is easily damaged, which seriously restricts the production of oil wells and increases workover operations....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com