Piezoelectrically Driven Dual-Axis Tilting Sample Holder for Transmission Electron Microscopy

An electron microscope, piezoelectric drive technology, applied in circuits, discharge tubes, electrical components, etc., can solve the problems of a large number of transmission parts, raising or lowering, connecting rods, etc., achieving small size, simple structure, and rapid response. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

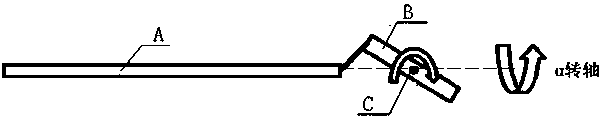

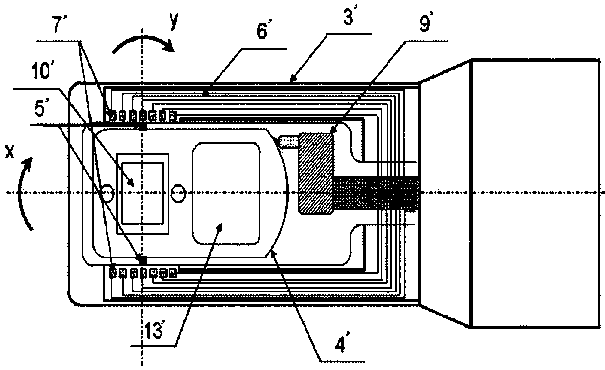

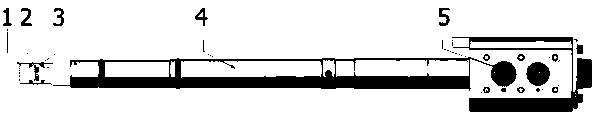

[0019] Such as image 3 As shown, the piezo-electrically driven dual-axis tilting sample rod for transmission electron microscope mainly includes a handle 5, a sample rod shaft 4, a sample rod head 1 and a sample cup 2 for loading samples. The sample cup 2 and Axis 9 is fixed, The shaft 9 is rotatably mounted on the head end 1 of the sample rod. The signal connection port of the sample rod 4 is arranged on the handle 5 . The sample cup 2 is mounted on the sample rod head end support 3 of the sample rod head end 1 .

[0020] Sample rod tip 1 set drive The drive member 10 of shaft 9 step-by-step rotation, drive member 10 and The shaft 9 is in close contact, and when the driving member 10 moves from the first position to the second position, Axis 9 steps an angular travel ; When the driver 10 is reset from the second position to the first position, The shaft 9 is fixed; the drive member 10 moves from the first position to the second position and resets from the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com