Soft pack lithium battery tab connection device

A technology of soft-pack lithium batteries and connection devices, which is applied to battery pack parts, circuits, electrical components, etc., can solve the problems of small thickness of soft-pack lithium batteries, inconvenient welding operations, waste of resources, etc., and achieve saving in assembly process and structure Simple, easy-to-install effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to further explain the technical means and effects adopted by the present invention to achieve the intended purpose of the invention, the specific implementation method, Steps, structures, features and their functions are described in detail.

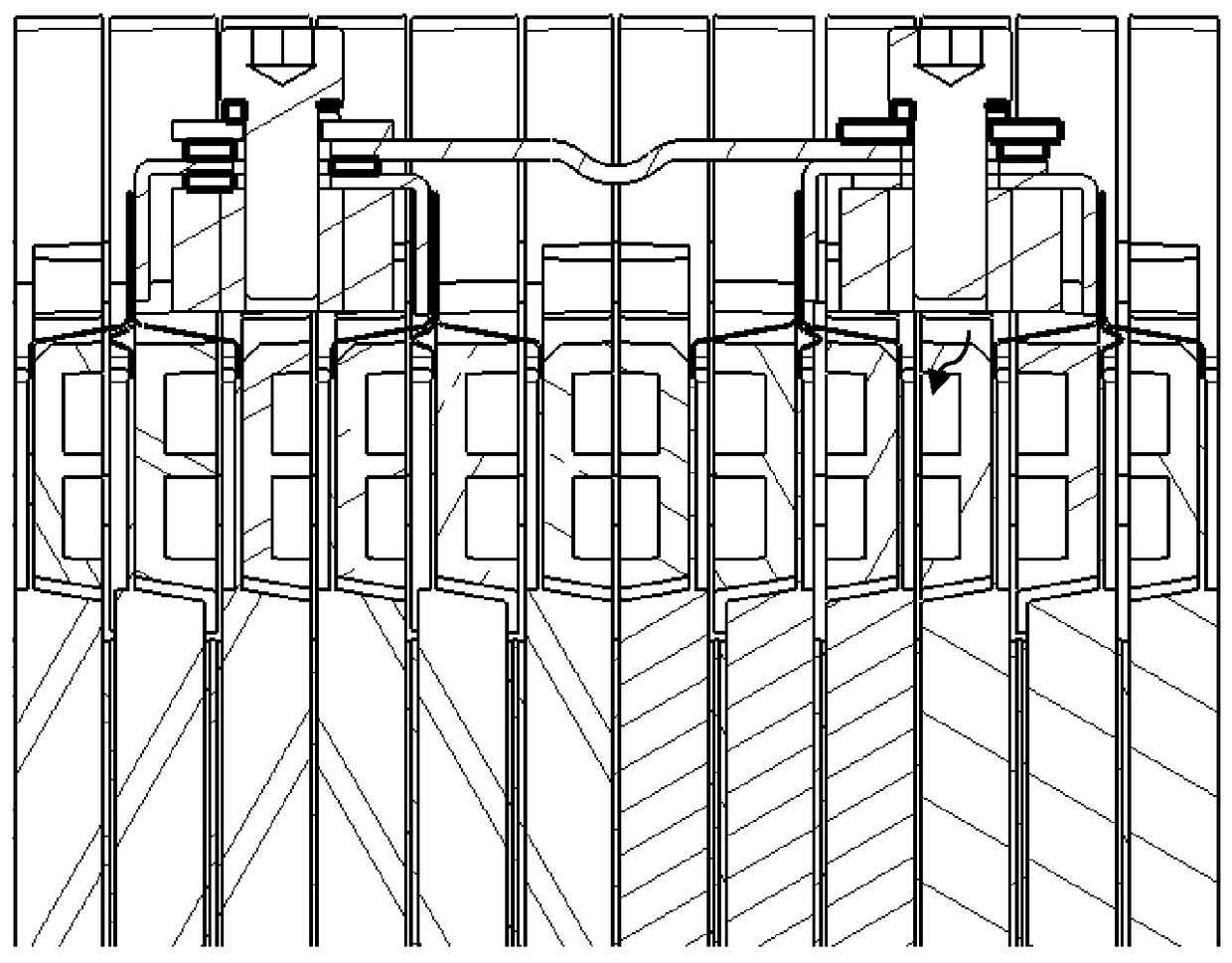

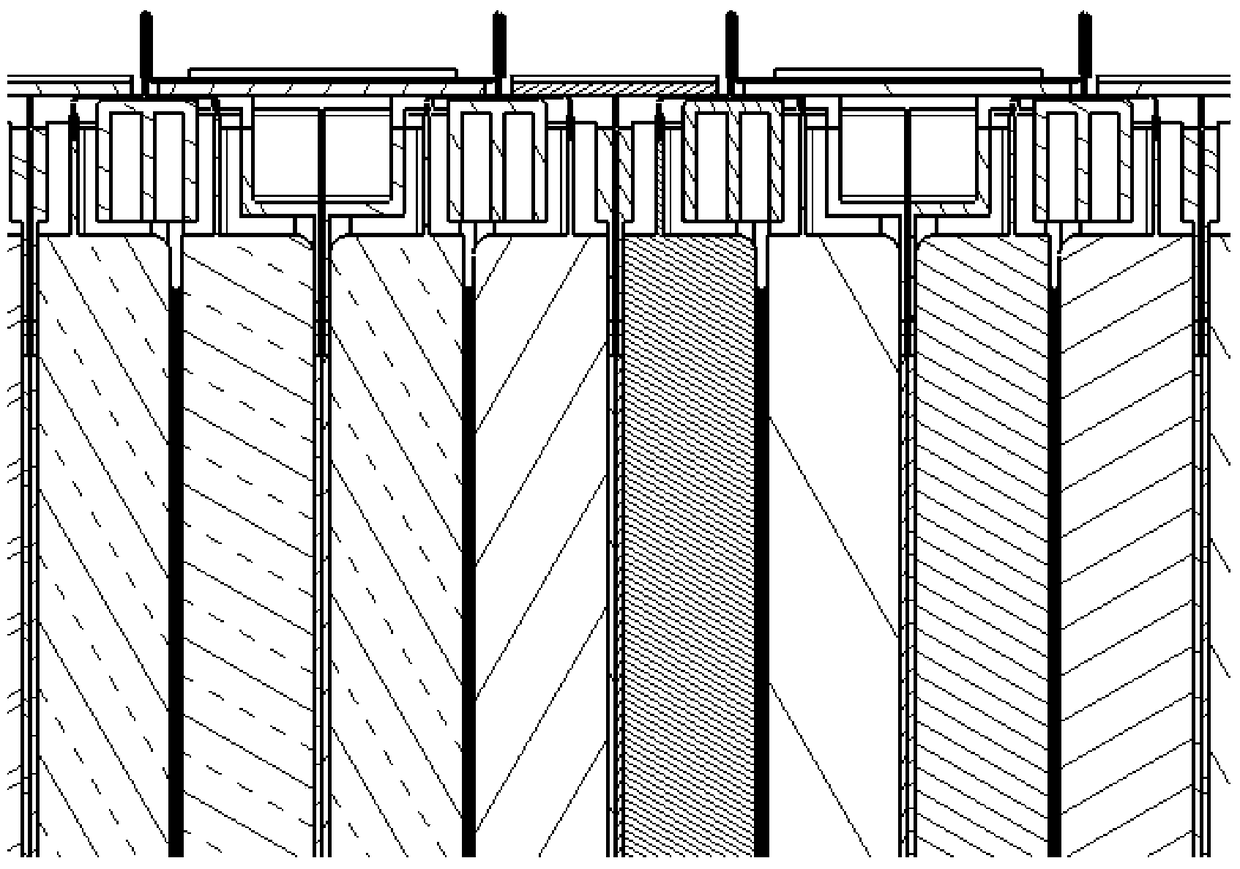

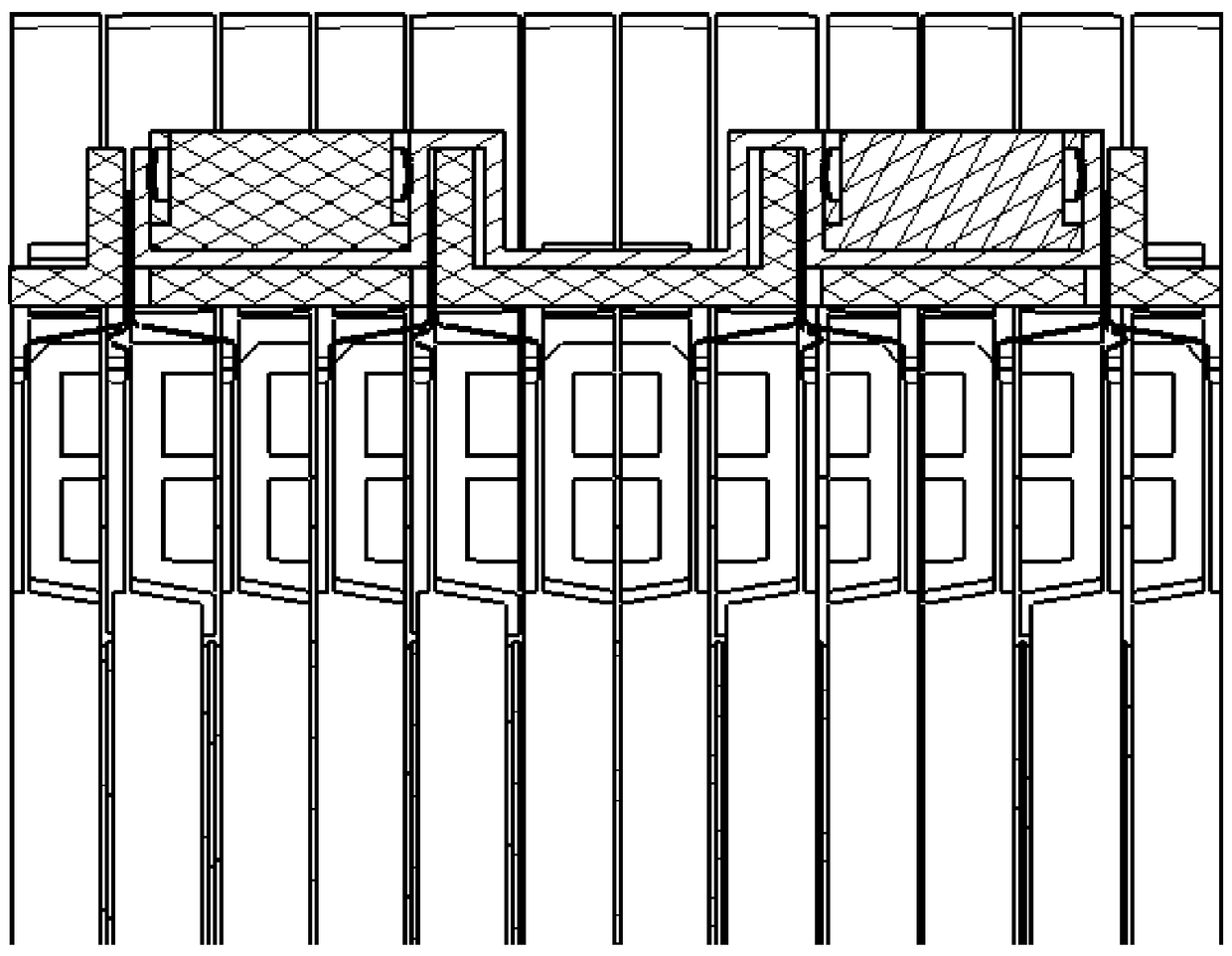

[0036] The lug connection device of the soft-pack lithium battery of the present invention is mainly composed of a tightening block 1 , a lug connection piece 2 and an integrated board 3 . Among them, a through groove 3-4 is opened on the integrated board 3, a stopper 3-2 is provided on the integrated board 3 on the side of the through groove 3-4, and the tab connecting piece 2 is stuck in the through groove 3-4 , the tightening block 1 is installed on the integrated board 3, and the flexible contact finger 6 is arranged on the tightening block 1, and the flexible contact finger 6 has a contact 6-1, and the contact 6-1 is in contact with the lug connecting piece 2. When a plurality of batteries 4 are assembled together,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com