Power cell module with reinforced heat radiation function

A power battery and battery module technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of high heat storage capacity, heat energy that is difficult to transfer to the outside, high requirements for leak-proof sealing, and high process costs, and achieve diverse functions and responsiveness. Short time, solve the effect of high temperature heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with specific examples, but the embodiments of the present invention are not limited thereto, and for the process parameters not specified in particular, it can be carried out with reference to conventional techniques.

[0025] Example.

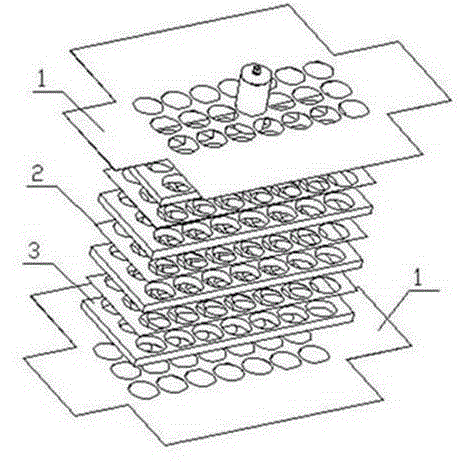

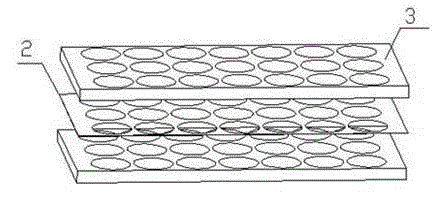

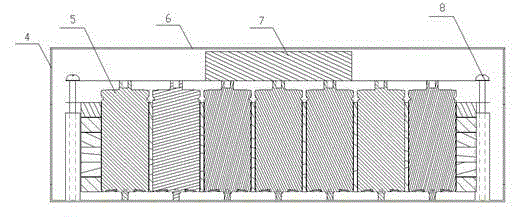

[0026] Such as figure 1 As shown, the present invention is based on a power battery module with an enhanced heat dissipation function. The composite material synthesized by composite phase change material / high thermal conductivity plastic can quickly absorb the heat generated when the battery is charged and discharged, and can keep the system temperature at a reasonable level. within the temperature range. In addition, through the high thermal conductivity graphite film between the interlayers of the composite material, the heat can be transferred laterally to the outside of the battery module, and then the external forced air cooling can be used for convective hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com