Power battery heat management system based on metal plate type pulse heat pipes

A thermal management system and pulsating heat pipe technology, applied in the direction of secondary batteries, circuits, electrical components, etc., can solve problems such as complex systems, large vehicle space, and difficult processing, achieve broad market prospects, solve high-temperature heat dissipation, and react short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with specific examples, but the embodiments of the present invention are not limited thereto, and for the process parameters not specified in particular, it can be carried out with reference to conventional techniques.

[0025] Example.

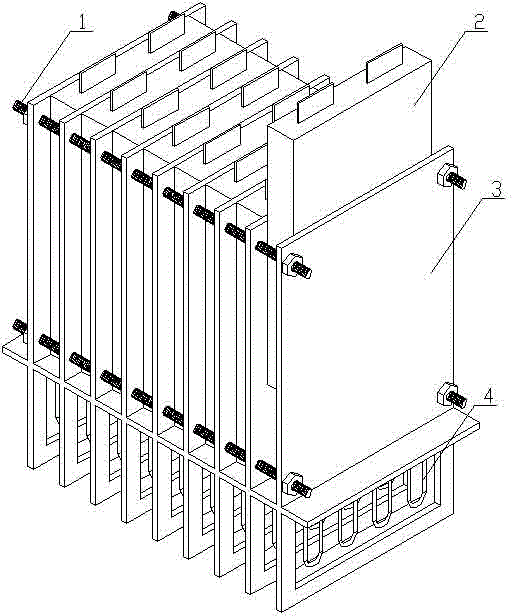

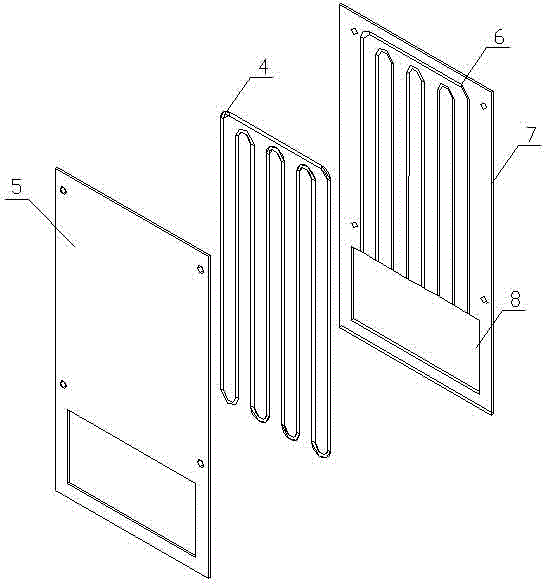

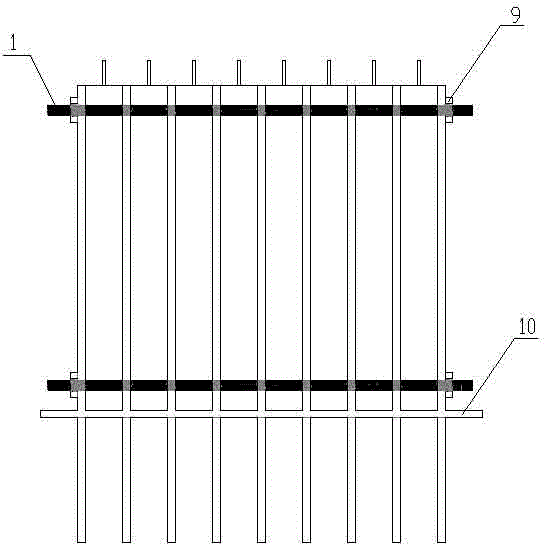

[0026] Such as figure 1 As shown, the power battery thermal management system based on the metal plate type pulsating heat pipe of the present invention transfers the heat generated by the square battery to the bottom of the power battery bracket through the metal plate type pulsating heat pipe 3 without external forced heat dissipation. The battery pack itself performs efficient thermal management. This system includes a power battery bracket 10 composed of metal plate type pulsating heat pipes, a battery module box 12, and a box top cover 11. Several single batteries 2 realized in series or parallel are placed on the bracket. The two sides of each square battery ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com