Heat-cycle drying energy saving system for Chinese prickly ash

An energy-saving system and heat cycle technology, applied in the fields of application, food processing, food science, etc., can solve the problems of uneven drying of "pepper", low drying efficiency, and unstable drying temperature, etc., to achieve improved certainty performance, improve drying efficiency and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

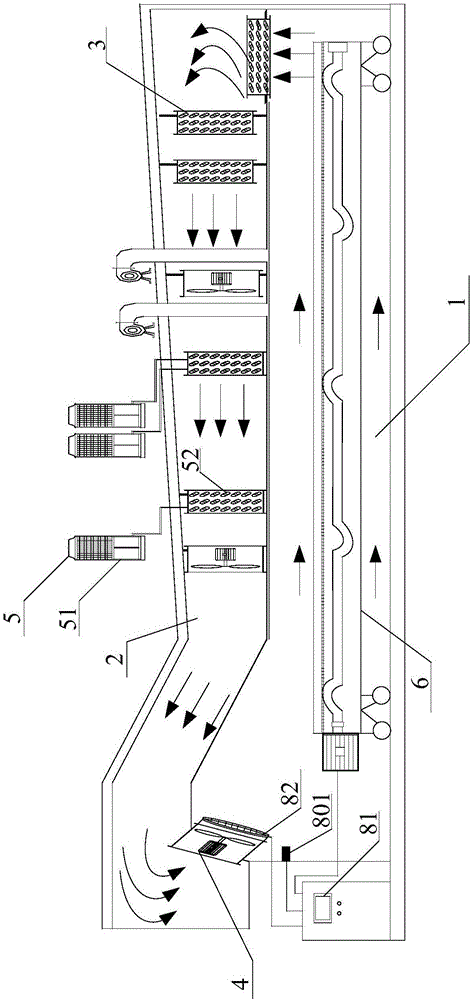

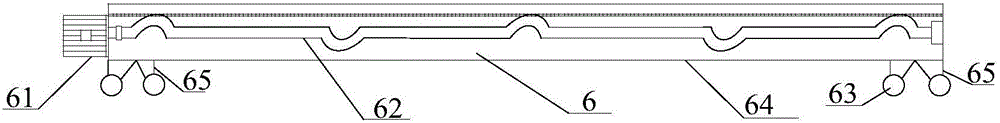

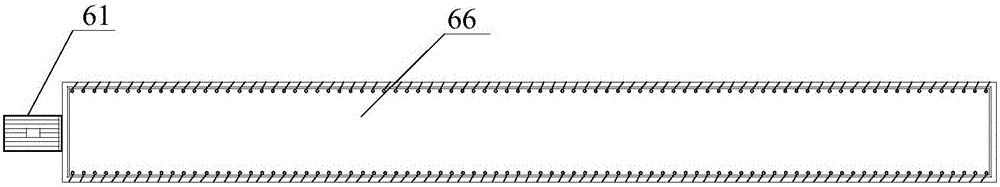

[0035] Such as figure 1 - As shown in -4, the present invention mainly consists of a control system, a temperature compensation device, a baking air duct 1, an air intake duct 2, a dehumidifier 3, an exhaust fan 4, a heating device 5, a vibrating drying rack 6, and a guide air Plate 7 composition. Among them, the vibrating drying rack 6 such as figure 2 Shown, it is made up of support 64, motor 61, stirring shaft 62, roller 63, roller mounting frame 65, and tarpaulin 66. At the same time, the temperature compensation device such as figure 1 As shown, it consists of a thermostat 81 and a heater 82.

[0036] During implementation, wherein, the baking air duct 1 is made of cement and bricks, and its inner bottom surface is provided with moving tracks matching the rollers 63 at the bottom ends of the bracket 64 of the vibrating drying rack 6 . Roller 63 of the present invention then preferably has adopted SG20 guide rail roller, and the present invention is provided with 4 SG...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com