A kind of preparation method of hexagonal boron nitride modified oil-absorbing sponge

A hexagonal boron nitride and oil-absorbing sponge technology, which is applied in the field of oil-absorbing sponges, can solve problems such as poor mechanical properties, low recycling rate, and complicated operation, and achieve good mechanical properties, low price and easy availability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

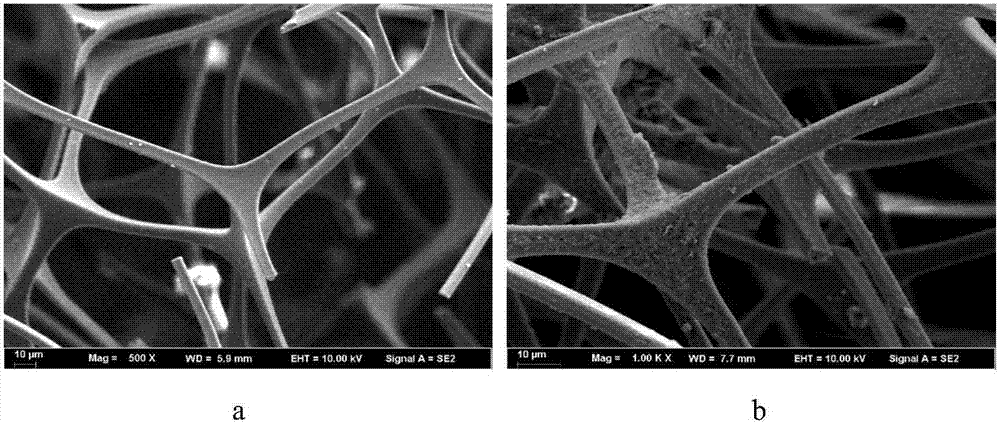

[0024] 1. Cleaning of melamine sponge:

[0025] Cut a large piece of melamine sponge into small cubes of suitable size (about 2cm 3 ), and then ultrasonically cleaned twice in deionized water and absolute ethanol respectively, each time for two hours, and then removed and dried at 80°C.

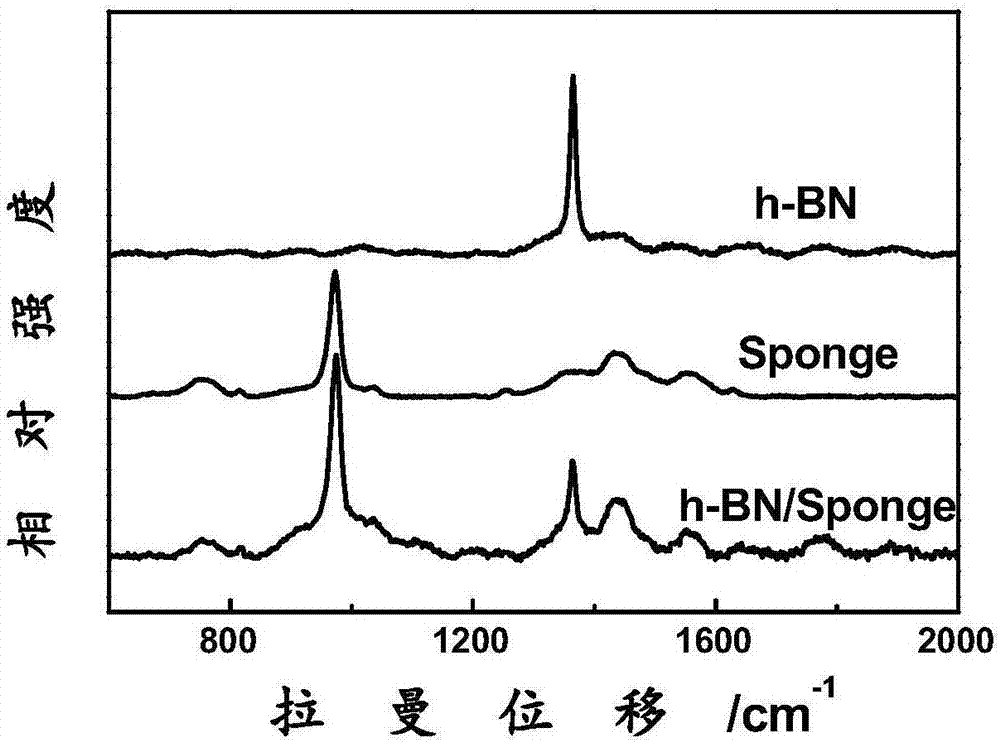

[0026] 2. Dispersion of h-BN:

[0027] Use an analytical balance to accurately weigh 100 mg of multi-layer h-BN powder with a thickness of 1-2 μm and pour it into a 150 ml beaker, use a graduated cylinder to accurately measure 100 ml of deionized water and pour it into the same beaker, and then ultrasonicate the solution for more than 24 hours. Then the white emulsion obtained after ultrasonication is poured into a centrifuge tube, put into a centrifuge for 25 minutes, and the rotating speed is 5000rpm; the upper two-thirds of the supernatant obtained after centrifugation is sucked out with a disposable dropper and transferred to In a clean beaker, remove the unexfoliated or multi-layered h...

Embodiment 2

[0032] 1. The cleaning of the melamine sponge is the same as the first embodiment.

[0033] 2. Dispersion of h-BN:

[0034] Use an analytical balance to accurately weigh 200 mg of multi-layer h-BN powder h-BN powder with a thickness of 1-2 μm and pour it into a 150 ml beaker, and accurately measure 100 ml of isopropanol (IPA) with a measuring cylinder and pour it into the same beaker. The solution was then sonicated for more than 24 hours. Then the white emulsion obtained after ultrasonication is poured into a centrifuge tube, put into a centrifuge and centrifuged for 40 minutes, and the rotating speed is 3000rpm; the upper two-thirds of the supernatant obtained after centrifugation is sucked out with a disposable dropper and transferred to In a clean beaker, remove the unexfoliated or multi-layered h-BN in the lower layer to obtain a uniformly dispersed h-BN nanosheet solution.

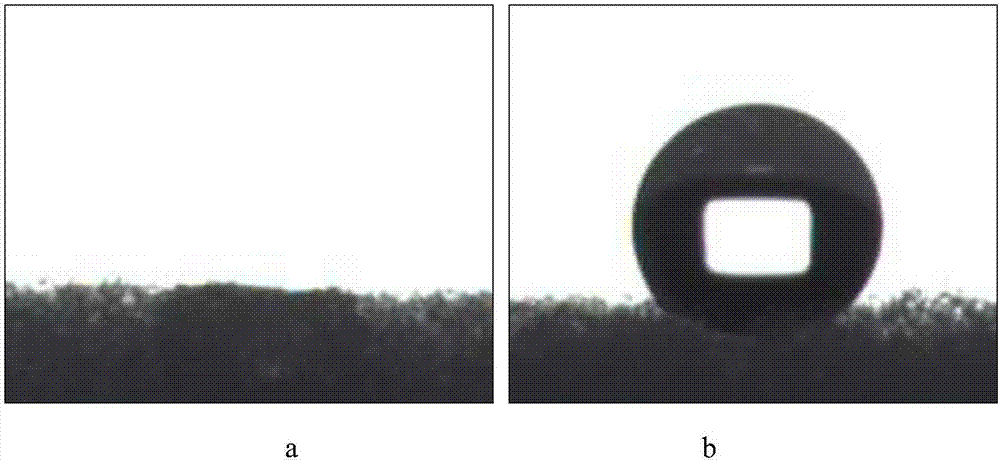

[0035] 3. Preparation of oil-absorbing sponge:

[0036] Immerse the melamine sponge obtained i...

Embodiment 3

[0039] 1. The cleaning of the melamine sponge is the same as the first embodiment.

[0040]2. Dispersion of h-BN:

[0041] Use an analytical balance to accurately weigh 100mg of multilayer h-BN powder with a thickness of 1-2μm and pour it into a 150ml beaker, and use a measuring cylinder to accurately measure 100ml of N-methylpyrrolidone (NMP) and pour it into the same beaker , the solution was then sonicated for more than 24 hours. Then the white emulsion obtained after ultrasonication is poured into a centrifuge tube, put into a centrifuge for 20 minutes, and the rotating speed is 6000rpm; the upper two-thirds of the supernatant obtained after centrifugation is sucked out with a disposable dropper, and transferred to In a clean beaker, remove the unexfoliated or multi-layered h-BN in the lower layer to obtain a uniformly dispersed h-BN nanosheet solution.

[0042] 3. Preparation of oil-absorbing sponge:

[0043] Immerse the melamine sponge obtained in step 1 into the unif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com