Automatic screening instrument applicable to fine particle cluster and use method of instrument

An automatic sieve and fine-grained technology, which is applied in the direction of chemical instruments and methods, instruments, scientific instruments, etc., can solve the problems of inability to separate fine-grained soil, large percentage of soil mass, and large Reynolds number Re, etc., to achieve ingenious structure , innovative thinking, and the effect of avoiding errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The preferred technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

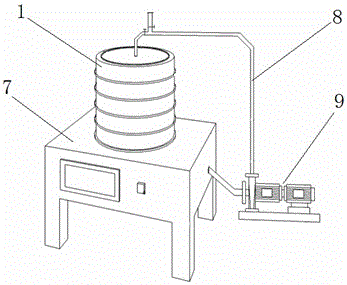

[0021] like figure 1 , 2 As shown, a kind of automatic screening instrument applicable to fine particle group of the present invention comprises a sieve box 1, and a screening device and a weighing device are arranged in the sieve box 1, and the screening device classifies fine particle materials according to different sizes. Layer screening, the weighing device will weigh the fine particle materials after layer screening;

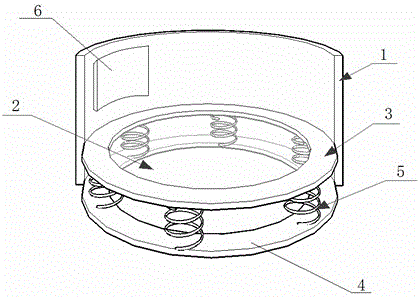

[0022] The screening device comprises a plurality of separation screens 2 that gradually change from large to small in the filter box 1 from top to bottom, and the separation screen 2 adopts a porous ceramic membrane sieve plate;

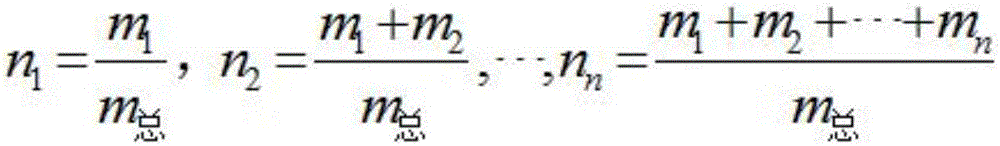

[0023] The weighing device comprises an induction upper ring 3, an induction lower ring 4 and a pressure spring 5, and a described separation screen 2 is located in the ring of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com