Automatic control method and system of electric tool

An automatic control system and power tool technology, applied in the direction of power tools, manufacturing tools, etc., can solve the problems of increasing the complexity of hardware and software design, low intelligence, and difficult to stop the number of laps, and achieve after-sales processing and maintenance. , The effect of high intelligence and convenient after-sales processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

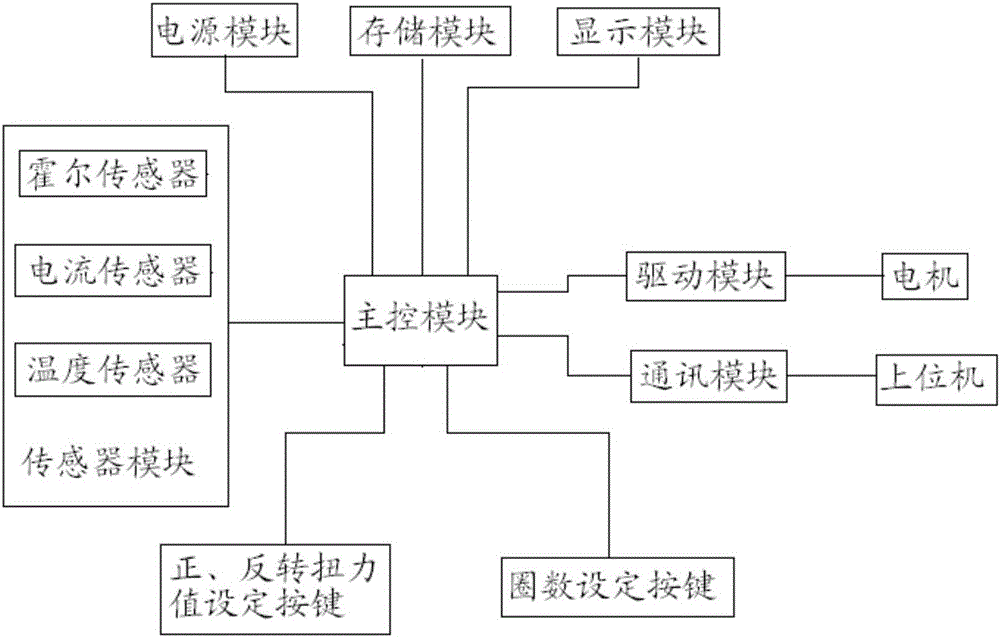

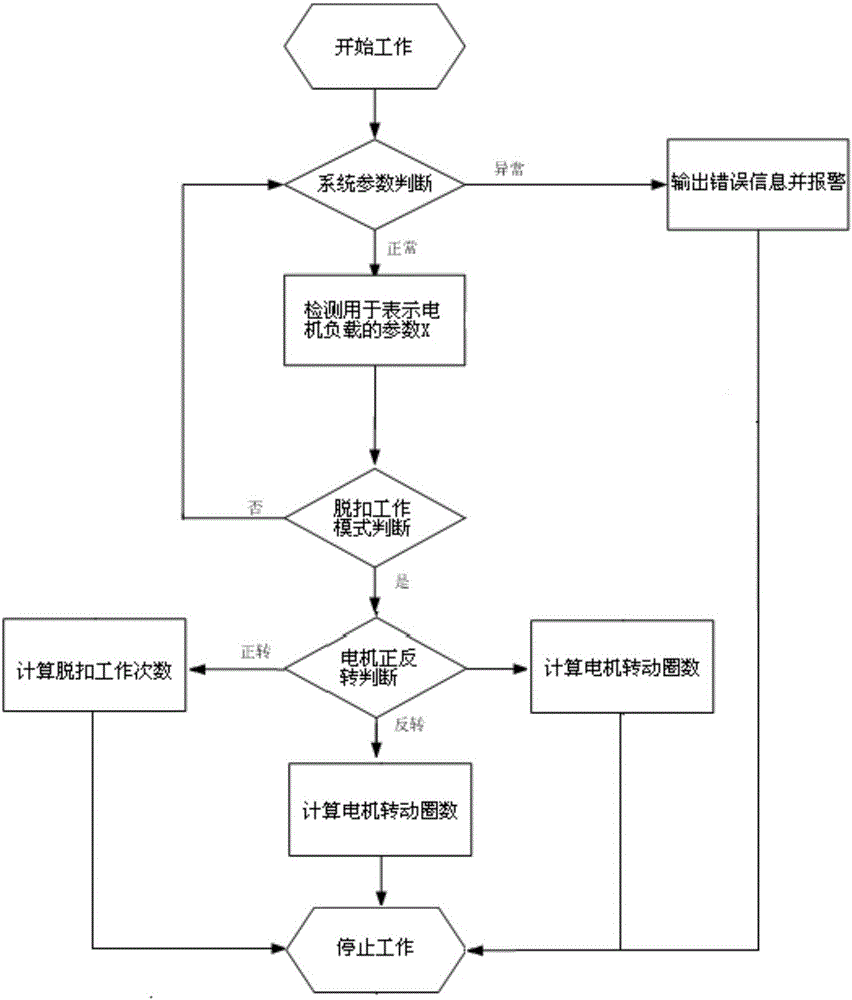

[0029] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to these embodiments.

[0030] When the electric tool is tightening or loosening the screw, due to the large external load blocking the rotation of the connecting component, it will cause the torsion spring to deform and produce periodic stress release. The stress is output to the load through the spring pushing the impact block. This process is electric The tripping mode of operation of the tool.

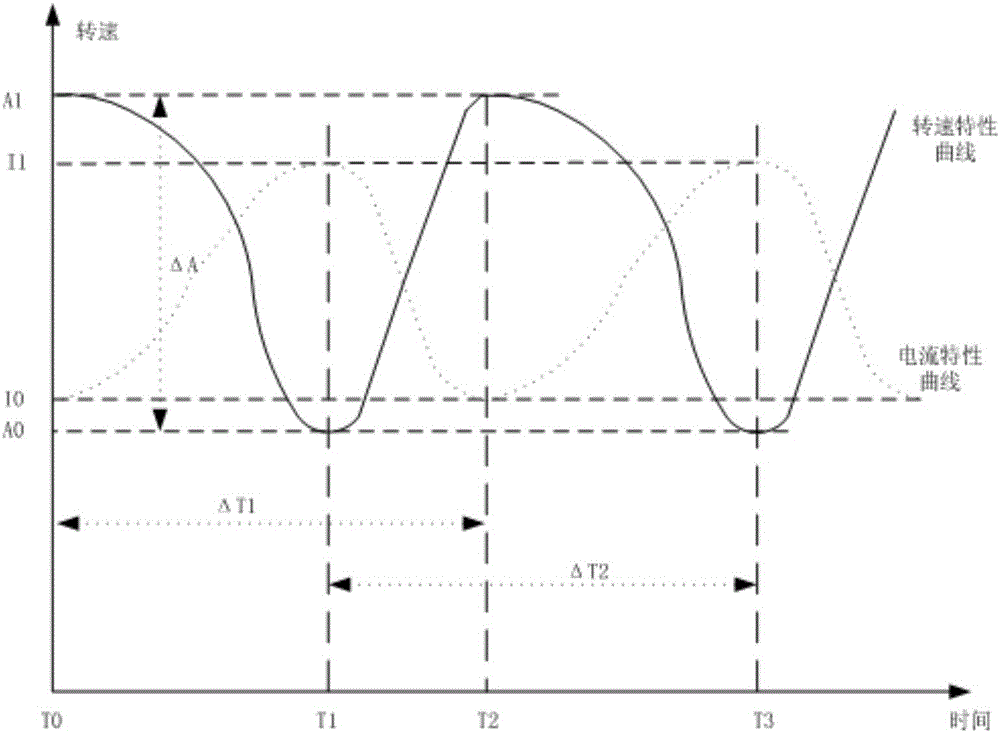

[0031] When the power tool enters the tripping mode, due to the different degrees of deformation of the torsion spring, the corresponding stresses are different. The greater the deformation of the torsion spring, the stronger the stress, the greater the corresponding motor load, the lower the motor speed, and the greater the circuit current. After the torsion spring reaches the deformation limit, the stress i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com