Film blowing machine with leftover material recycling device

A recycling device and film blowing machine technology, applied in plastic recycling, mechanical material recycling, recycling technology, etc., can solve problems affecting the uniformity of film production, improve raw material utilization, reduce local unevenness, and increase mixing Process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

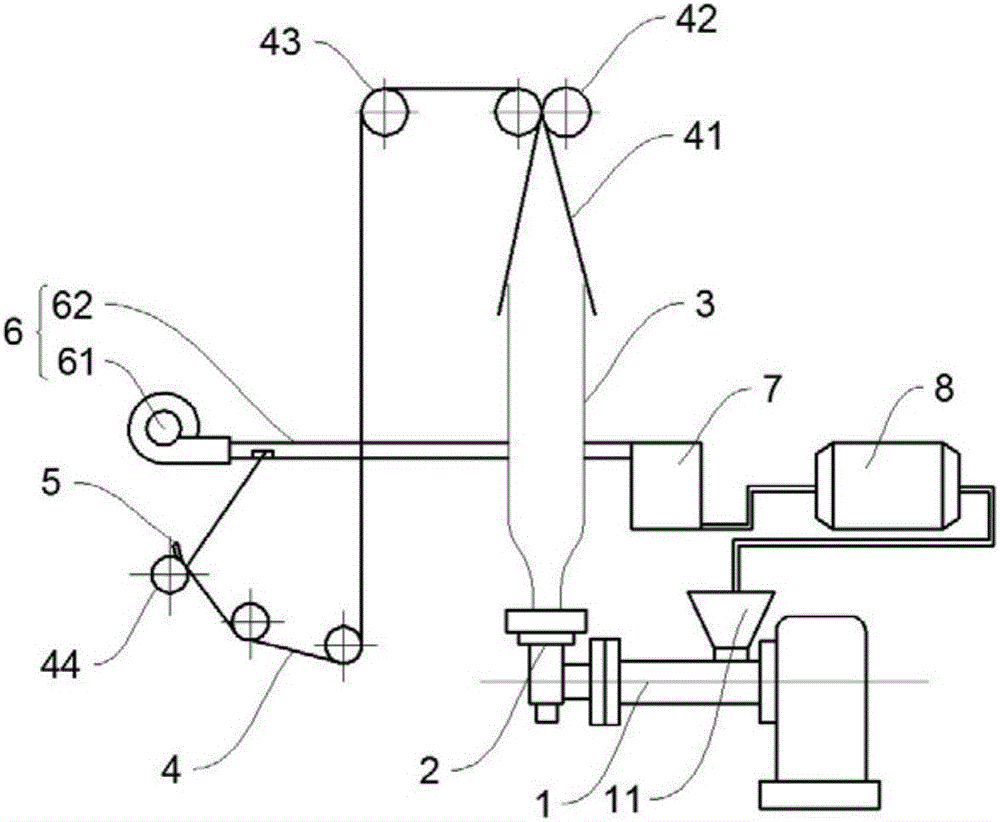

[0012] Such as figure 1 A film blowing machine with scrap recovery device shown, including extruder 1, machine head 2, roll collection system 4, cutter 5, side material transmission system 6, shredder 7, mixer 8; The extruder 1 is provided with a feeding hopper 11, the outlet of the extruder 1 is connected to the machine head 2, the film bubble 3 processed by the machine head 2 is collected by the roller system 4, and the leftover material is cut before the coiling device 44; 5. Cut the leftover material and transfer it to the shredder 7 through the side material transmission system 6. The outlet end of the shredder 7 is connected to the inlet end of the mixer 8, and the outlet end of the mixer 8 is connected to the hopper 11 of the extruder 1. The roll collection system 4 includes a herringbone plate 41 , a traction roll 42 , a guide roll 43...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com