Ply slippage prevention method for composite material parts

A composite material, anti-slip technology, applied in the field of composite material parts manufacturing, to achieve the effect of easy disassembly, improved product quality, and large comprehensive friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Taking the manufacture of honeycomb sandwich parts as an example, the specific process is as follows:

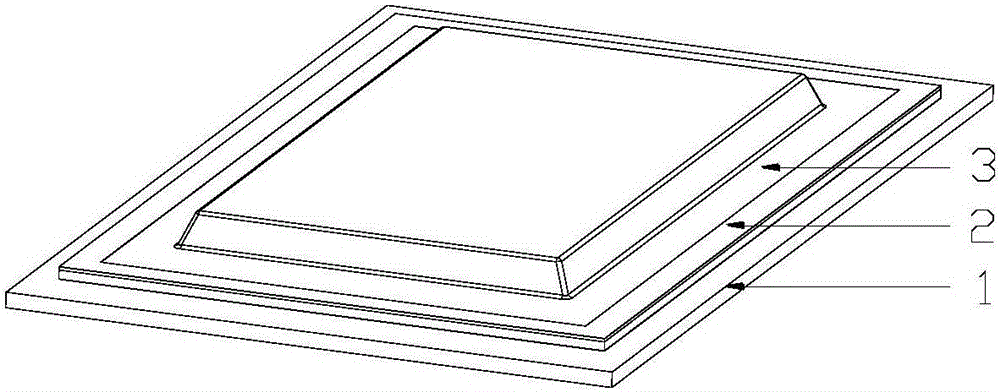

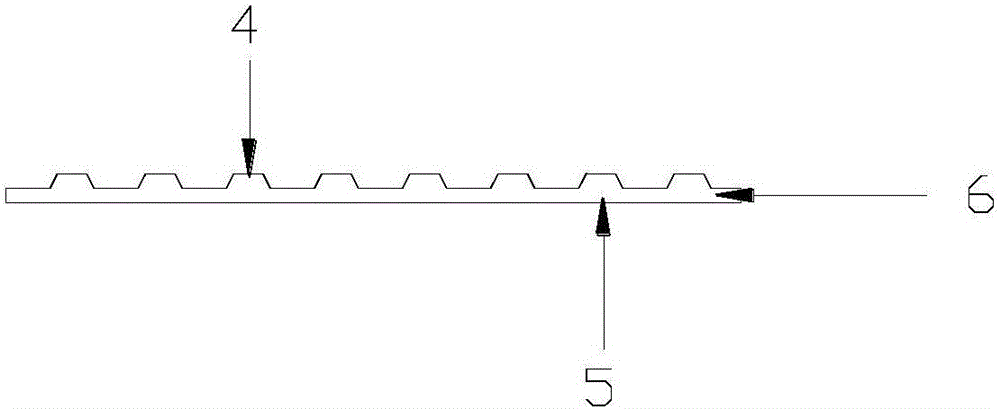

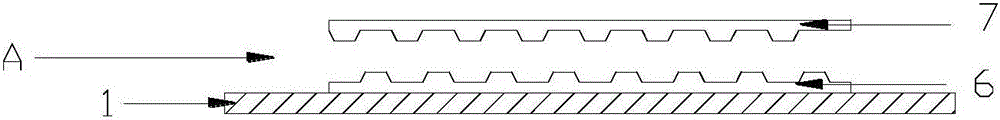

[0029] Such as Figure 1-Figure 4 Shown, comprise a group of upper anti-skid plate 6 and lower anti-skid plate 7, the structure of upper anti-skid plate 6 and lower anti-skid plate 7 is corresponding, all is the uneven surface with part contact side (anti-skid surface 4), and the other side ( The installation surface 5) is a smooth and flat surface, and used in pairs;

[0030] 1) Fix the lower anti-skid plate 7 in the spare part area 2 around the tooling 1, and the mounting surface 5 of the lower anti-skid plate 7 is in contact with the surface of the tooling 1;

[0031] 2) Evenly apply a release agent on the surface of the tooling 1 and the anti-skid surface 4 of the lower anti-skid plate 7;

[0032] 3) Starting from the surface of the tooling 1, lay the prepreg layer by layer, place honeycomb cores, inserts, secondary parts, etc., and the margin area of each lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com