Program-controlled hydraulic automatic transporting and stacking device

An automatic transportation and hydraulic technology, applied in the direction of transportation and packaging, conveyors, conveyor objects, etc., can solve the problems of low labor efficiency, increased labor efficiency, waste of manpower and land resources, etc., to improve labor efficiency and solve manpower and material resources , the effect of saving equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

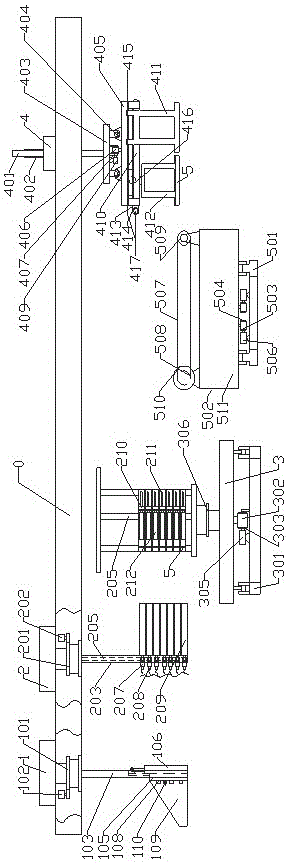

[0037] Accompanying drawing is the specific embodiment of the present invention. Such as Figure 1 to Figure 11 As shown, this kind of program-controlled hydraulic automatic transportation and coding device is controlled by the PLC control system to run the whole device. It includes an aerial track 0 erected in the air. The aerial track 0 is a double-track track. There is a No. No. 2 tackle 2 and No. 4 tackle 4 (these three tackles running on the sky track 0 are prior art, and no longer describe the specific structure of their operation in detail here), wherein:

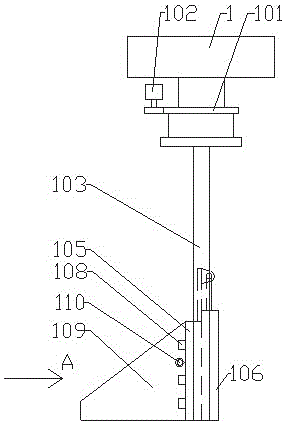

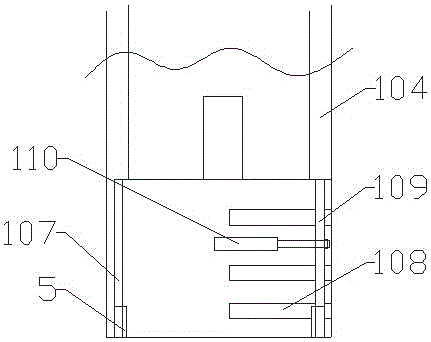

[0038] Such as Figure 1 to Figure 4 As shown, a No. 1 gear 101 is installed at the lower end of the No. 1 pulley 1, and the No. 1 gear 101 is engaged with the gear shaft at the output end of the No. 1 longitudinal hydraulic motor 102. The No. 1 longitudinal hydraulic motor 102 drives the No. 1 gear 101 to rotate. The gear 101 is fixedly connected with the No. 1 hanger 103. The No. 1 hanger 103 includes two paralle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com