Method for preparing nano-polycrystalline coesite through high-pressure phase transition method

A phase change method and polycrystalline Ke technology, applied in the field of inorganic materials, can solve problems such as adsorption, difficulty in dispersion, and agglomeration, and achieve the effect of high purity and uniform phase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Example 1: Select microcrystalline α-SiO with an average particle size of 10 μm 2 Micropowder, prepare nano polycrystalline coesite material according to the technological process shown in the present invention. Raw material treatment: microcrystalline α-SiO 2 The raw material was stirred and cleaned with absolute ethanol, and when it settled, the upper liquid was poured out, and the α-SiO 2 The micropowder is dried in an oven at 120°C. Add an appropriate amount of deionized water as a binder to make α-SiO 2 The micropowder has a certain humidity, and it is pre-pressed and molded, and the molded sample is put into an oven to dry, and the deionized water that is the most binder is removed.

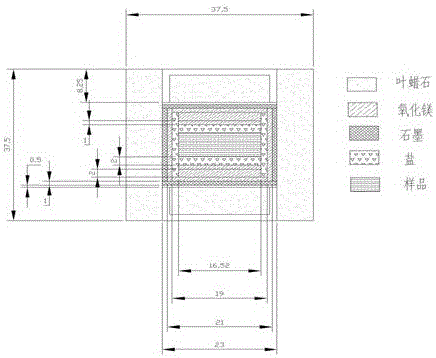

[0019] Put the completely dried sample into a metal cup, pre-press it again, and put it into the synthesis chamber, such as figure 1 shown. Among them, the components mainly include insulation materials, heating sheets, heating tubes, wrapping tubes, wrapping sheets, insulation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com