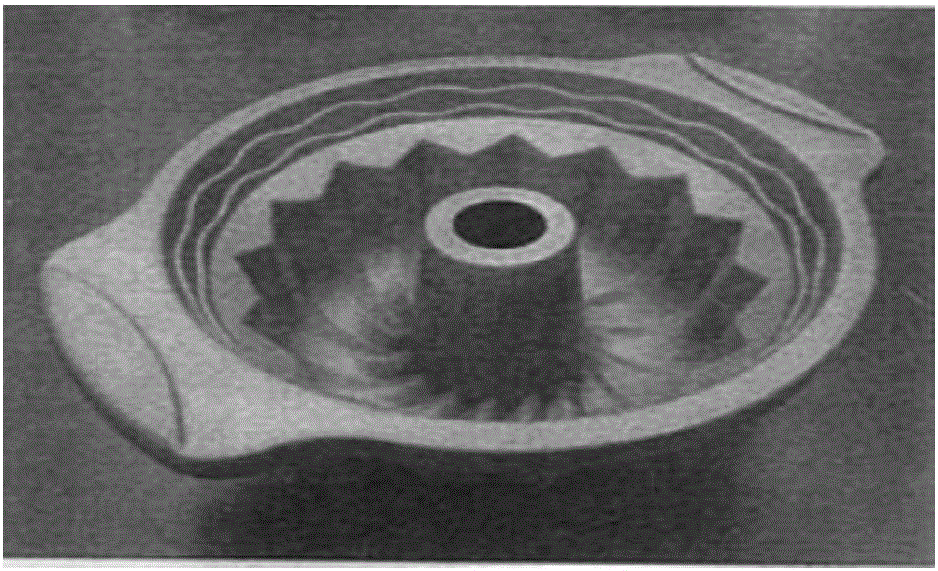

Plastic baking tray

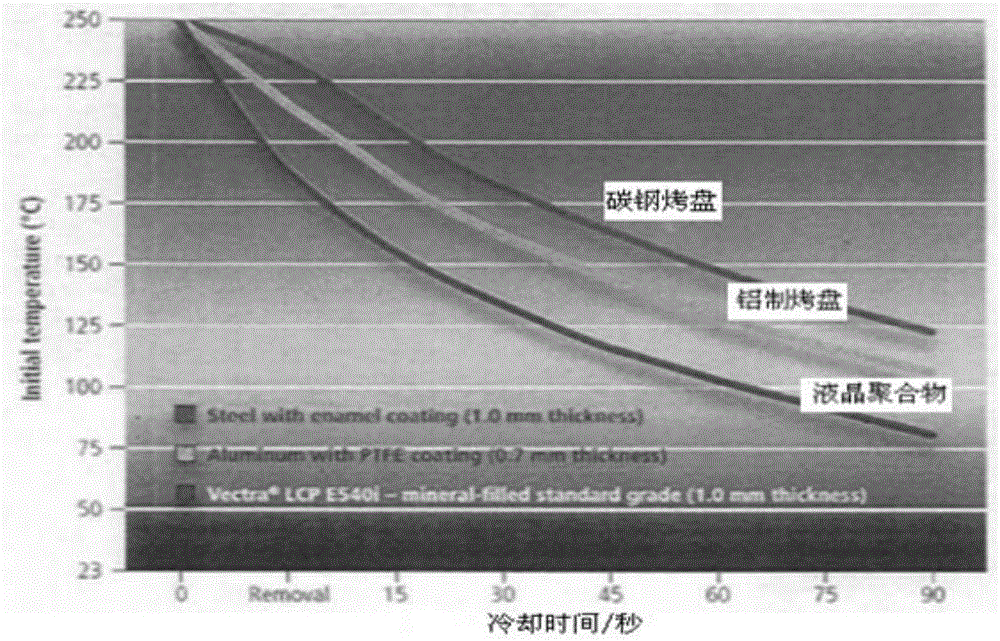

A bakeware and plastic technology, which is applied in the field of kitchen utensils, can solve the problems that the bakeware cannot withstand for a long time, affects the performance of food grade, and the composition of materials is complicated, and achieves the effect of shortening the baking time, shortening the heating and cooling time, and simple ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The raw materials were weighed according to the components and parts by weight of Example 1 in Table 1, and the raw materials were pre-dried at a temperature of 160° C., and the pre-drying time was 7 hours. Then the weighed raw materials are fully mixed and added into the barrel. The temperature of the front section of the barrel is 360°C, the temperature of the middle section is 350°C, and the temperature of the back section is 330°C. It is heated to a molten state, and the melt temperature is 330°C. Then inject it into a mold with a temperature of 100° C. through a nozzle of a hot runner, and the injection speed is 35 seconds per mold to obtain a plastic baking tray.

Embodiment 2

[0039] The raw materials were weighed according to the components and parts by weight of Example 2 in Table 1, and the raw materials were pre-dried at a temperature of 160° C., and the pre-drying time was 7 hours. Then the raw materials are fully mixed and added into the barrel. The temperature of the front section of the barrel is 360°C, the temperature of the middle section is 350°C, and the temperature of the back section is 330°C. It is heated to a molten state, and the melt temperature is 330°C. Then it is injected into a mold with a temperature of 100° C. through a nozzle of a hot runner, and the injection speed is 36 seconds per mold to obtain a plastic baking tray.

Embodiment 3

[0041] The raw materials were weighed according to the components and parts by weight of Example 3 in Table 1, and the raw materials were pre-dried at a temperature of 170° C., and the pre-drying time was 7 hours. Then the weighing materials are fully mixed and added into the barrel. The temperature of the front section of the barrel is 365°C, the temperature of the middle section is 355°C, and the temperature of the back section is 335°C. It is heated to a molten state, and the melt temperature is 340°C. Then inject it into a mold with a temperature of 110° C. through a nozzle of a hot runner, and the injection speed is 38 seconds per mold to obtain a plastic baking tray.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com