High-performance 5xxx series aluminium alloy and processing method thereof

A processing method and technology of aluminum alloy, applied in the field of non-ferrous metals, can solve the problems of limiting the application range of 5 series stamping sheets, high processing costs, poor mechanical properties and surface effects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

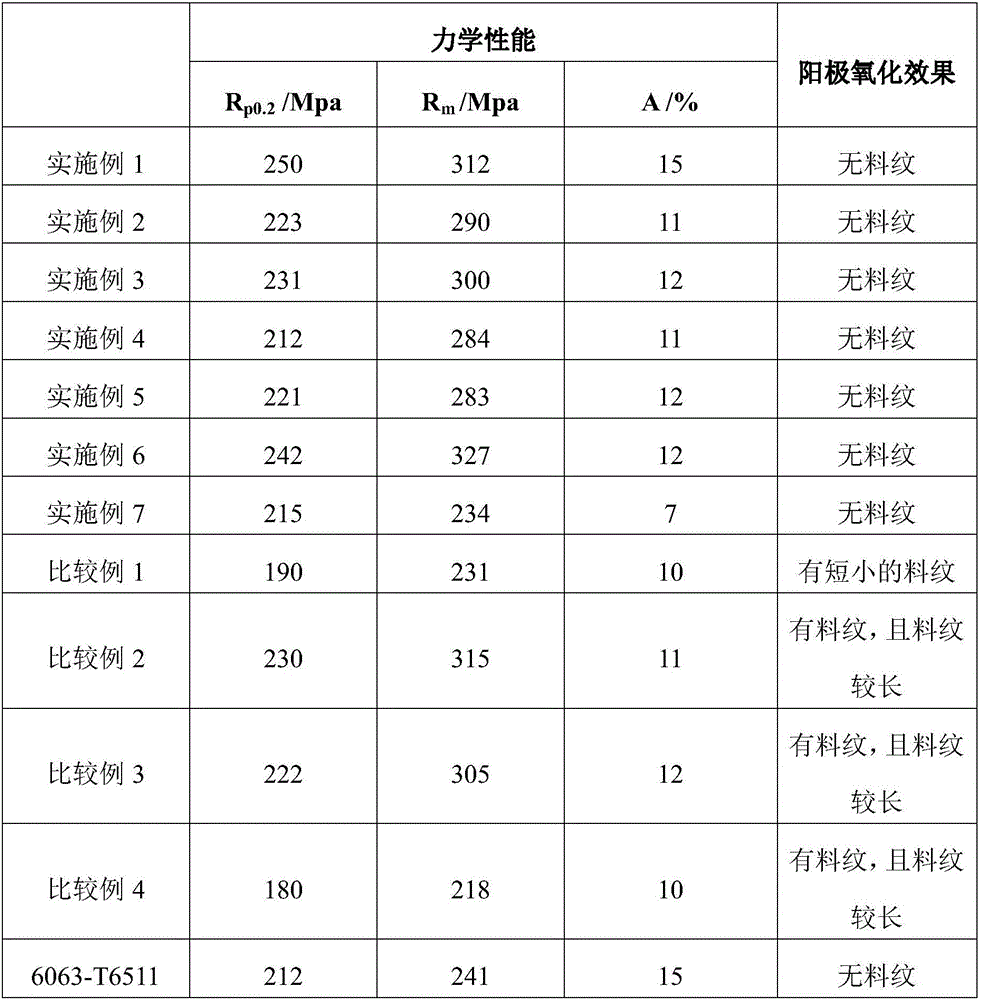

Examples

Embodiment 1

[0020] The composition of ingot aluminum alloy is calculated by mass percentage: Mg: 4.2wt%, Si: 0.03wt%, Cu: 0.06wt%, Mn: 0.001wt%, Cr: 0.01wt%, Fe: 0.08wt%, Ti: 0.01 wt%, the balance is Al.

[0021] Homogenizing heat treatment of alloy ingots: heat preservation at 420°C for 8 hours, then rise to 500°C for 6 hours; then perform hot rolling, the starting temperature is 500°C, and the final rolling temperature is controlled below 320°C; for cold-rolled billets Subsequent cold rolling is carried out, and when the total reduction is 70%, intermediate annealing is carried out at 300°C for 4h.

Embodiment 2

[0023] The composition of ingot aluminum alloy is calculated by mass percentage: Mg: 3.2wt%, Si: 0.05wt%, Cu: 0.001wt%, Mn: 0.001wt%, Cr 0.002wt%, Fe 0.10wt%, Ti 0.01wt%, The balance is Al.

[0024] Homogenizing heat treatment of alloy ingots: heat preservation at 430°C for 5 hours, then rise to 510°C for 8 hours; then perform hot rolling, the starting temperature is 500°C, and the final rolling temperature is controlled below 280°C; for cold-rolled billets Subsequent cold rolling is carried out, and when the total reduction is 50%, intermediate annealing is carried out at 300°C for 6h.

Embodiment 3

[0026] The composition of ingot aluminum alloy is calculated by mass percentage: Mg: 4.8wt%, Si: 0.06wt%, Cu: 0.001wt%, Mn: 0.001wt%, Cr: 0.001wt%, Fe: 0.12wt%, Ti: 0.02 wt%, the balance is Al.

[0027] Homogenizing heat treatment for alloy ingots: keep warm at 440°C for 6 hours, then raise to 520°C for 5 hours; Subsequent cold rolling is carried out, and when the total reduction is 80%, intermediate annealing is carried out at 320° C. for 4 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mechanical properties | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com