A method for producing free-cutting steel using stibnite

A technology for free-cutting steel and stibnite, which is applied in the fields of iron and steel metallurgy and metal materials, can solve the problems such as environmental pollution caused by smelting of stibnite, and achieves the effects of reducing production costs and solving environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

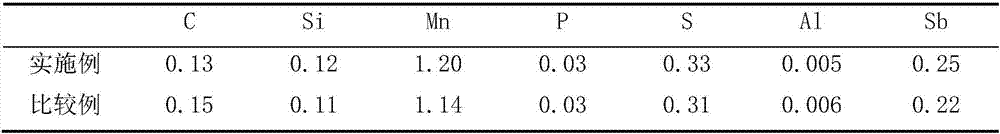

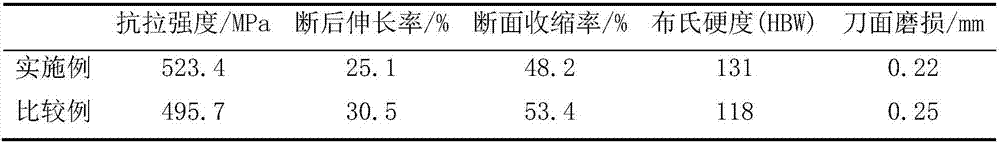

[0029] One, the preparation of free cutting steel of the present invention

[0030] The main chemical composition of natural stibnite is Sb 2 S 3 , the content generally exceeds 98%. According to the literature, when the stibnite ore is formed, due to mechanical or physical and chemical effects, it is often mixed with a small amount of dioxide, silicon, iron, tin, arsenic, germanium, copper, lead, zinc, nickel and cobalt and other impurities, the impurity content is less than 1%.

Embodiment 1

[0032] Add 0.4% of stibnite to the 100kg vacuum induction furnace. The adding time of stibnite is after the molten steel is deoxidized and before alloying. When adding stibnite, the oxygen activity of molten steel is 120×10 -6 , the addition of stibnite is 0.4kg, and 0.4kg of ferrous sulfide is added.

Embodiment 2

[0034] Add 0.2% of stibnite to the 100kg vacuum induction furnace. The time to add stibnite is after the molten steel is deoxidized and before alloying. When adding stibnite, the oxygen activity of molten steel is 120×10 -6 , the addition of stibnite is 0.2kg, adding 0.1kg of metal antimony and 0.5kg of ferrous sulfide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com