Compound core spun yarn

A technology of core-spun yarn and core-spun yarn, which is applied in the field of core-spun yarn, which can solve the problems of low wearing performance, poor softness, and unsatisfactory fibers, and achieve the effects of excellent comprehensive performance, loose structure, and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

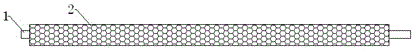

[0015] A composite core-spun yarn, comprising: a core yarn 1 and a covering yarn 2.

[0016] Wherein, the core yarn includes nylon filaments and bamboo fibers with a mass ratio of 1:3, the nylon filaments are silver-plated nylon filaments, and the bamboo fibers are randomly distributed among the nylon filaments. The covering yarn covers the outer periphery of the core yarn in a net shape. The fineness of the silver-plated nylon filament after compounding is 40D / 25f.

[0017] The covering yarn 2 is a mesh yarn layer woven from Tencel and cashmere, and its mesh structure is circular.

Embodiment 2

[0019] A composite core-spun yarn, comprising: a core yarn 1 and a covering yarn 2.

[0020] Wherein, the core yarn includes nylon filaments and bamboo fibers with a mass ratio of 2:3, the nylon filaments are silver-plated nylon filaments, and the bamboo fibers are randomly distributed among the nylon filaments. The covering yarn covers the outer periphery of the core yarn in a net shape. The fineness of the silver-plated nylon filament after compounding is 60D / 70f.

[0021] The covering yarn 2 is a mesh yarn layer woven from Tencel and cashmere, and its mesh structure is rhombus.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com