Graphene composite functional coating fabric and preparation process thereof

A graphene composite and coated fabric technology, which is applied in textiles and papermaking, furniture parts, household appliances, etc., can solve problems such as high prices, inability of ordinary people to consume, and single function, so as to reduce production difficulty and cost and improve production efficiency. Use effect and market prospect, effect of expanding product audience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

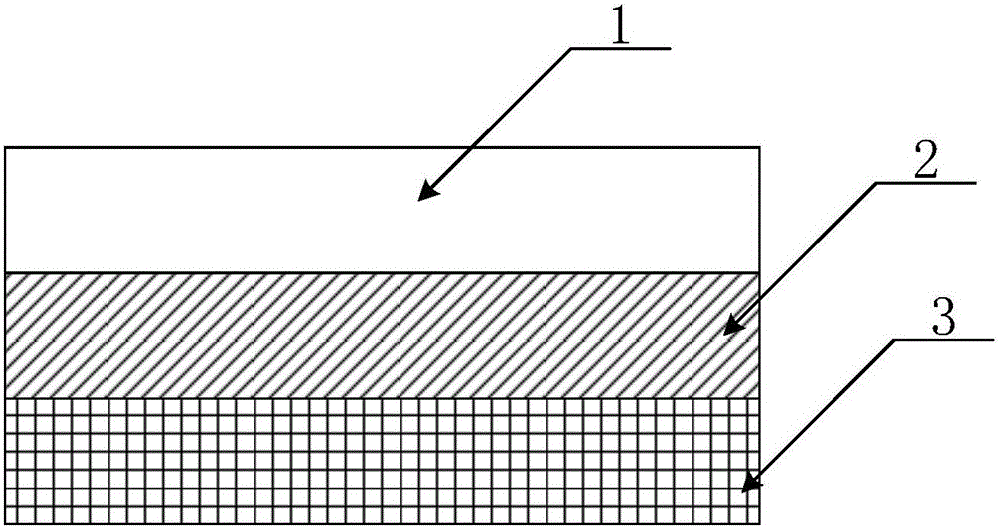

[0029] Such as figure 1 As shown, a graphene composite functional coated fabric includes a resin functional base cloth 3, a microcapsule layer 2 disposed on the resin functional base cloth 3, and a composite layer 1 disposed on the microcapsule layer 2.

[0030] Preferably, the resin functional base fabric 3 is a base fabric coated with a resin film on the surface. The resin film can make the base fabric have better water-releasing and air-permeable properties, further improving the comfort of the product.

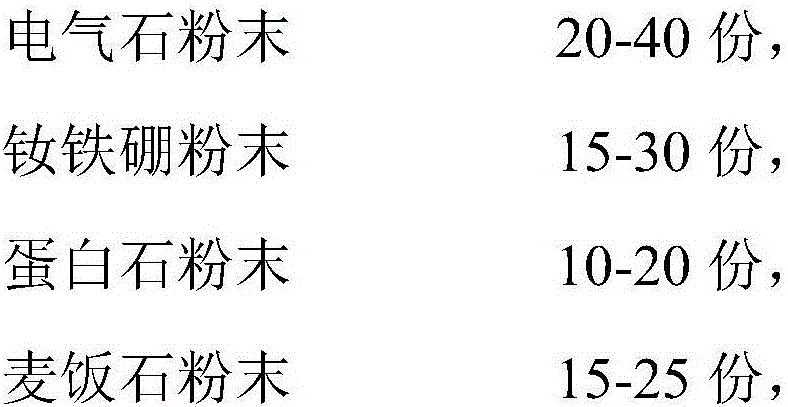

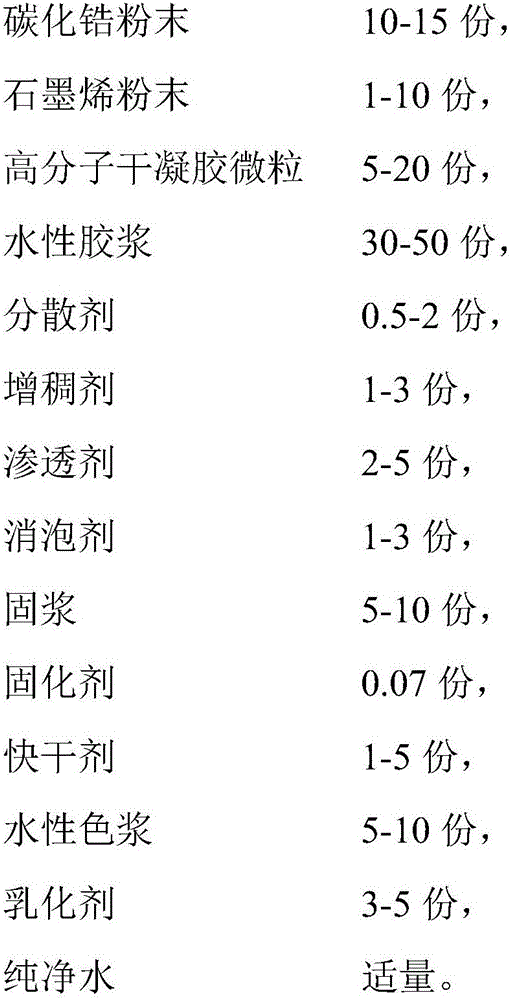

[0031] Wherein, composite pulp is made up of the component of following weight part:

[0032]

[0033] The graphene is one or both of graphene oxide powder and modified vapor-phase deposited graphene powder.

Embodiment 2

[0035] The difference between this embodiment and embodiment 1 is that the microcapsule layer 2 is composed of microcapsules, which are microcapsules containing traditional Chinese medicine, microcapsules containing mosquito repellent substances, or microcapsules containing fragrance.

[0036] The microcapsules are selected according to different requirements.

[0037] If you choose microcapsules containing traditional Chinese medicine, the traditional Chinese medicine ingredients in the microcapsules can be selected from different existing formulas according to specific needs, so as to provide them to people with different needs.

[0038] If the microcapsule containing the mosquito repelling substance is selected, the existing plants or medicines for mosquito repelling are put into the microcapsule.

[0039] If the microcapsules containing fragrance are selected, plants or medicines that can emit fragrance are put into the microcapsules.

Embodiment 3

[0041] This embodiment is a kind of Chinese medicine formula in the present invention of Example 2, wherein the Chinese medicine ingredients and parts by weight are: 150 parts of cloves, 150 parts of curcuma, 200 parts of red peony, 150 parts of earthworm, 150 parts of loofah .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com