Separate combined powerhouse system for tubular hydropower station

A tubular hydropower station technology, applied in the field of hydropower stations, can solve the problems of large investment, increased height of the main plant building of the hydropower station, and large buoyancy force of the tubular hydropower station

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, wherein the schematic embodiments and descriptions are only used to explain the present invention, but are not intended to limit the present invention.

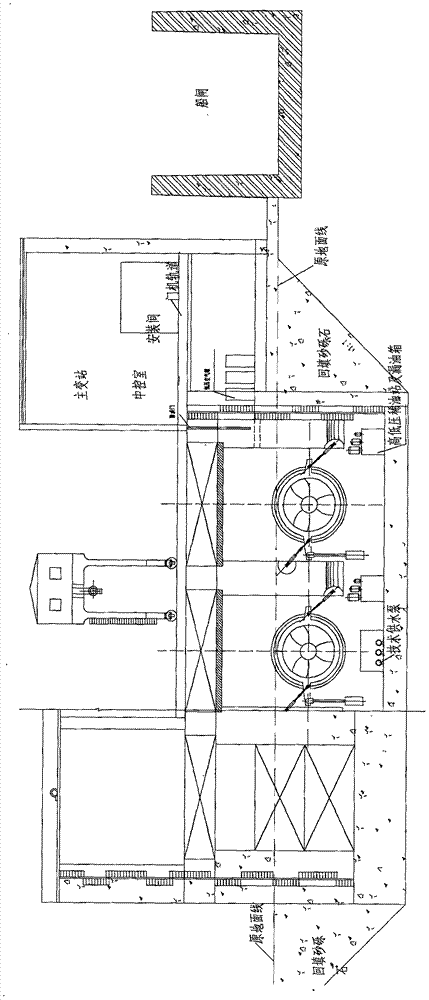

[0026] Such as figure 1 As shown, the separate combined powerhouse system of the tubular hydropower station described in this specific embodiment adopts the following method steps:

[0027] Step 1: Divide the traditional cross-flow unit and machine pier, electrical room, auxiliary equipment room, booster station and other parts, so that each part is independent of each other and can be flexibly combined and arranged;

[0028] Step 2: Place the tubular unit and machine pier in the river, and arrange the retaining gate dam on it;

[0029] Step 3: Within the range of the power generation head, the river sluice dam blocks the water, the upper part of the concrete pier of the unit is exposed to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com