Ceiling cascade device and installation method

A technology for drop ceiling and roof plate, applied in the field of building decoration, can solve the problems of heavy workload, difficult clearance, sound insulation, poor thermal insulation and moisture resistance, etc., to reduce construction difficulty and construction labor intensity, reduce installation and construction procedures, save money The effect of installation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with examples. Wherein the same components are denoted by the same reference numerals. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "inner" and "outer ” refer to directions towards or away from the geometric center of a particular part, respectively.

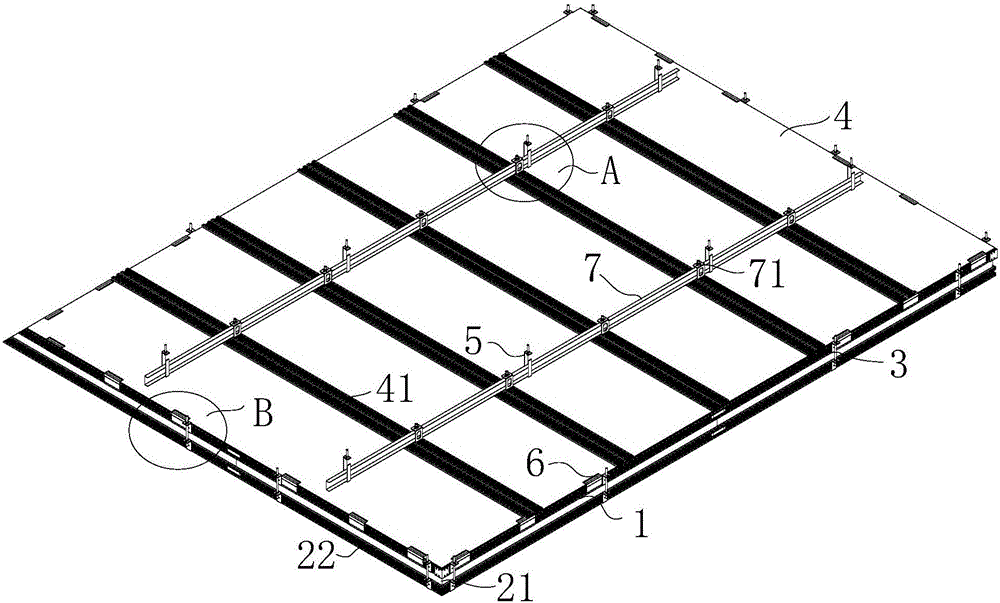

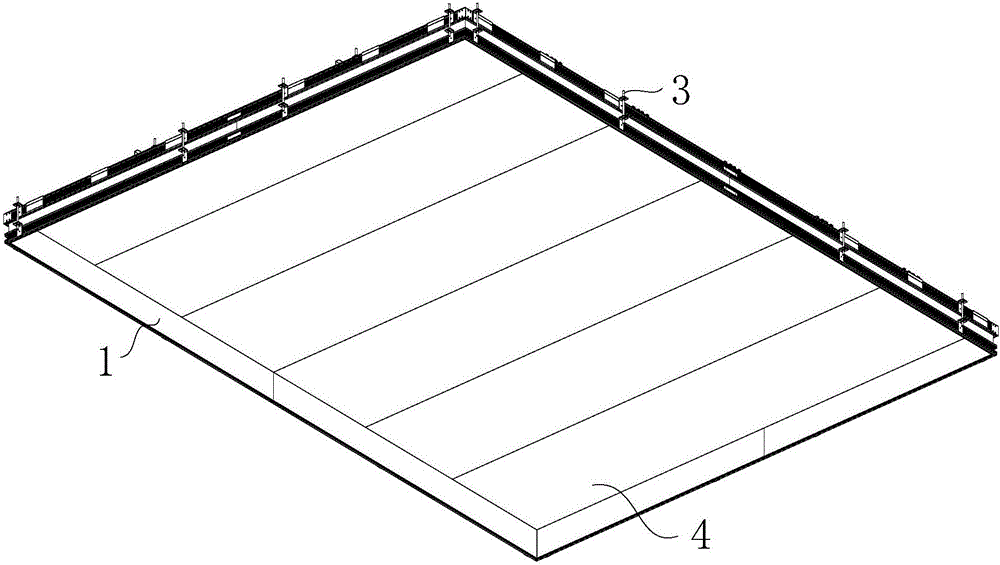

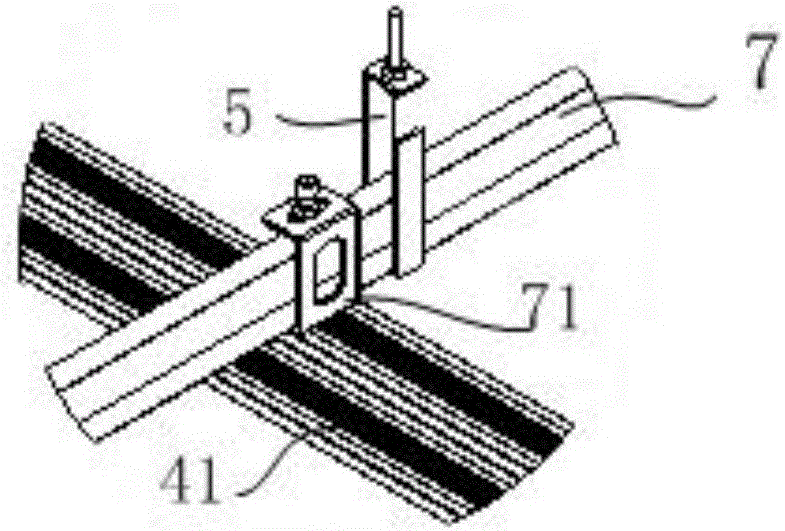

[0030] figure 1 A preferred embodiment of the structure of the ceiling drop device provided by the present invention, figure 2 for figure 1 bottom view of image 3 for figure 1 Partial enlarged view of A, Figure 4 for figure 1 Partial enlarged view of B in middle, Figure 5 For the preferred embodiment of the structure of the roof provided by the present invention, Figure 6 A preferred embodiment of the structure of the vertical frame provided by the present invention, Figure 7 A preferred embodiment of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com