Efficient drain water recovery box

A hydrophobic recovery and high-efficiency technology, used in machines/engines, mechanical equipment, engine components, etc., can solve problems such as damage to the environment, energy waste, leakage, etc., and achieve the effect of easy condensation, large contact area, and good steam absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

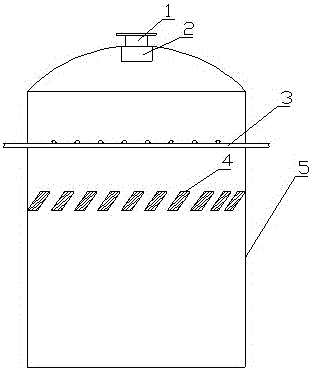

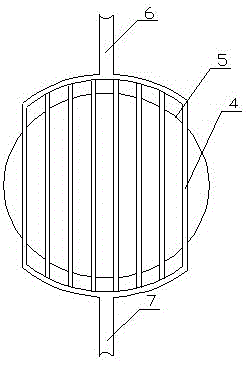

[0016] Such as figure 1 , figure 2 As shown, the present invention discloses a high-efficiency hydrophobic recovery box, comprising a cylindrical box body 5, a spray pipe 3, steam condensation fins and an air outlet 1, the cylindrical box body 5 is a vertical thin-walled tube, spraying The shower pipe 3 has a number of criss-crossing pipes, all of which are horizontally built into the cylindrical box 5, with spray holes evenly distributed on it; , including several parallel condensing fins 4, the condensing fins 4 are hollow plate-shaped tubes arranged horizontally, filled with condensate inside, the condensate is cheap and easy to obtain water with a large specific heat capacity, and the air outlet 1 is set On the upper part of the cylindrical box, the lower end is also provided with a filter screen cover 2 built in the cylindrical box 5; the condensing fins 4 are inclined, and the angle between the plane where it is located and the horizontal plane is 30-75 degrees to incr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com