Vehicle body vibration restraining method of electric vehicle resonance power generation based on effort wasting lever

A technology of electric vehicles and levers, applied in the direction of mechanical power generation mechanisms, vehicle components, machines/engines, etc., can solve problems such as unfavorable resonance power generation, reduce vibration energy conversion efficiency, etc., and achieve high-efficiency vibration and high-efficiency utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

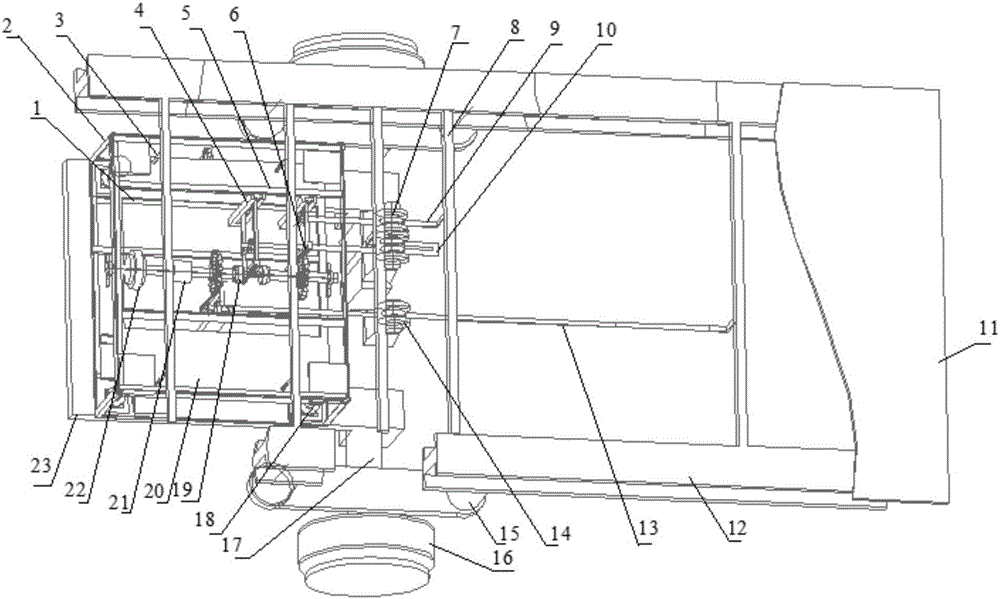

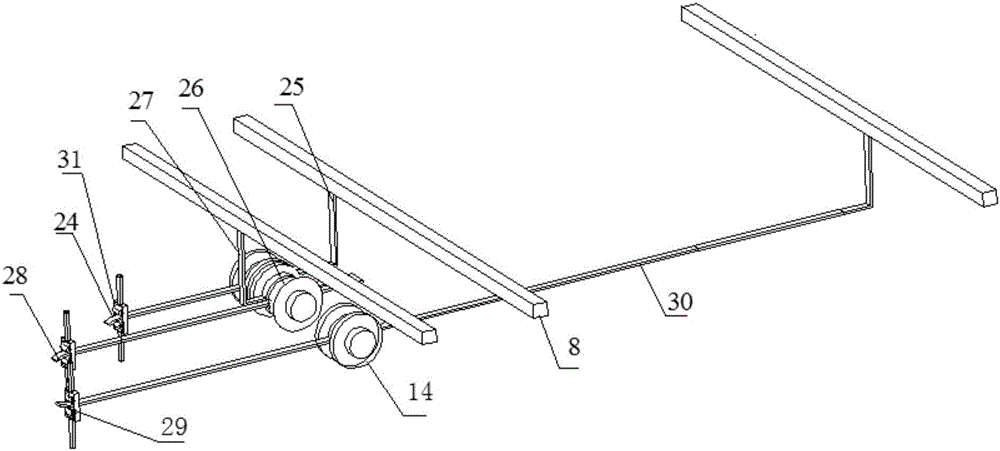

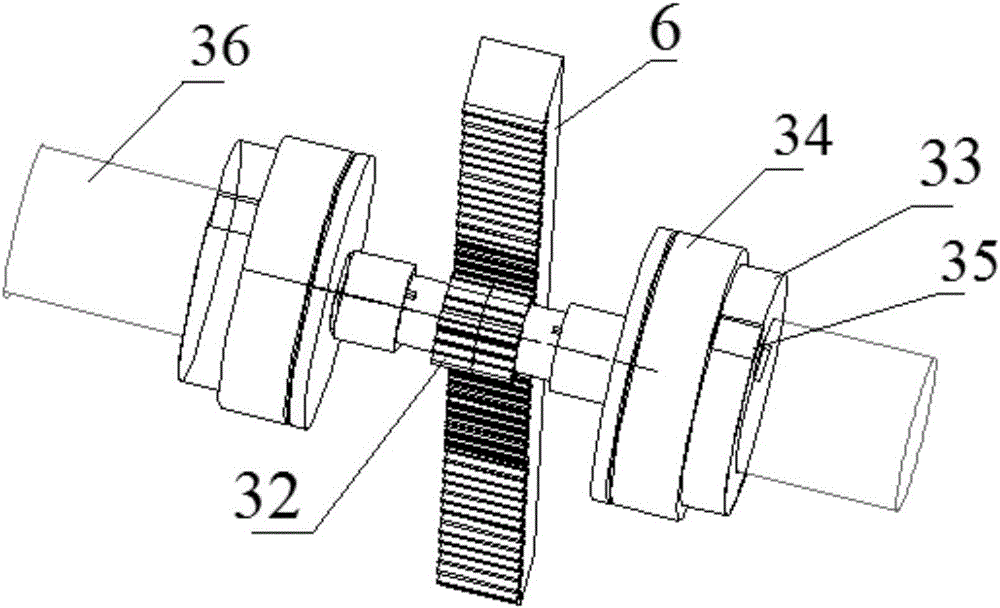

[0016] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

[0017] In the current invention of the method of applying frequency resonance to automobile kinetic energy power generation, it is impossible to completely solve the sudden bumps in the driving process of electric vehicles. The traditional vibration suppression of the vehicle body is to pass the vibration energy of the vehicle body through the shock absorber Or vibration-damping leaf springs can be used to generate frictional damping and heat dissipation. If placed on a car kinetic energy generator that passes frequency resonance, it will reduce the conversion efficiency of vibration energy, which is not conducive to resonance power generation.

[0018] This application proposes a body vibration suppression method based on a laborious lever for electric vehicle resonance power generation, which includes a kinetic energy generating device arranged on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com