Hydraulic system of bulldozer

A technology for hydraulic systems and bulldozers, applied in mechanical equipment, fluid pressure actuating devices, accumulator devices, etc., can solve problems such as increasing system heat generation, increasing engine power loss, and reducing overall machine fuel utilization efficiency, etc. The effect of reducing power loss and reducing overflow loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

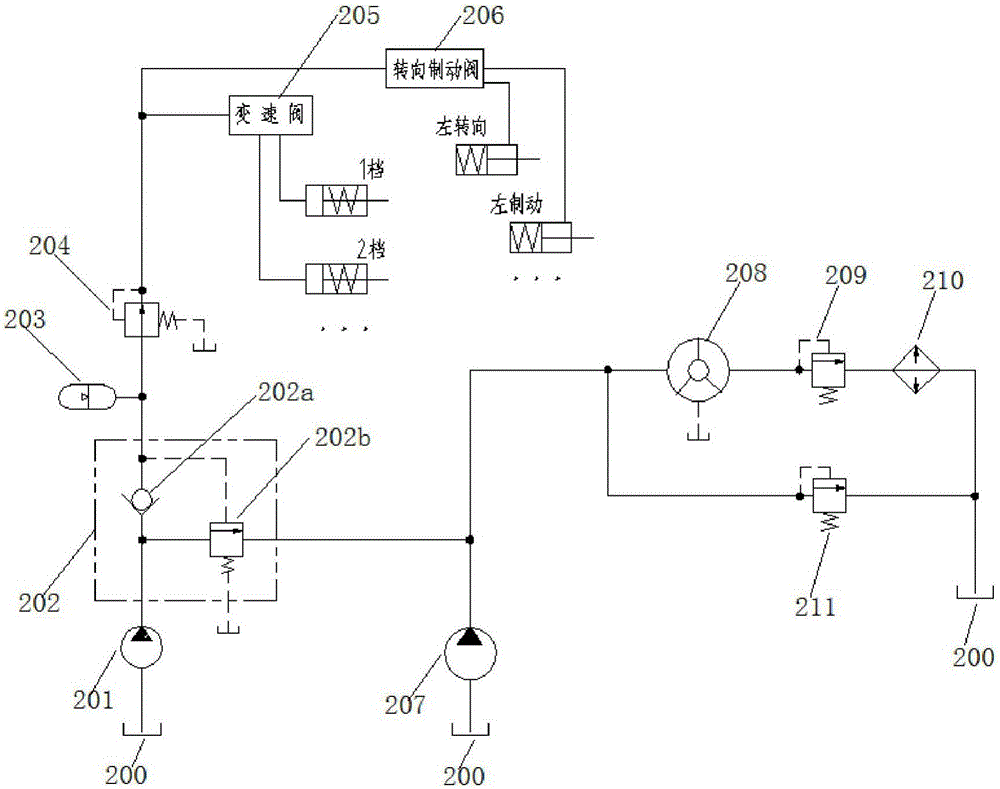

[0022] The invention provides a bulldozer hydraulic system, which includes a first oil circuit and a second oil circuit;

[0023] Such as figure 2 As shown, the oil in the first oil circuit is divided into two circuits after the oil tank 200 passes through the pump I201, the unloading valve 202, the accumulator 203 and the pressure reducing valve 204 in sequence, one of which communicates with the transmission valve 205, and the other It communicates with the steering brake valve 206; the pump I201 is a high-pressure small displacement hydraulic pump; the set pressure of the pressure reducing valve 204 is 2MPa;

[0024] Such as figure 2 As shown, the oil in the second oil circuit returns to the oil tank 200 after passing through the pump II207, torque converter 208, back pressure valve 209 and oil cooler 210 from the oil tank 200, and the inlet of the torque converter 208 is connected to the oil A torque converter overflow valve 211 is arranged between the outlets of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com