Sensible heat accumulating type direct steam generation system based on parallel connection regulation as well as method

A generation system, heat storage technology, applied in steam generation method, steam generation method using solar energy, steam generation, etc., can solve the problems of unadjustable heat exchange area, change of heat storage system, unstable output power, etc. The effect of reducing complexity and investment, reducing heat exchange equipment, and facilitating adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

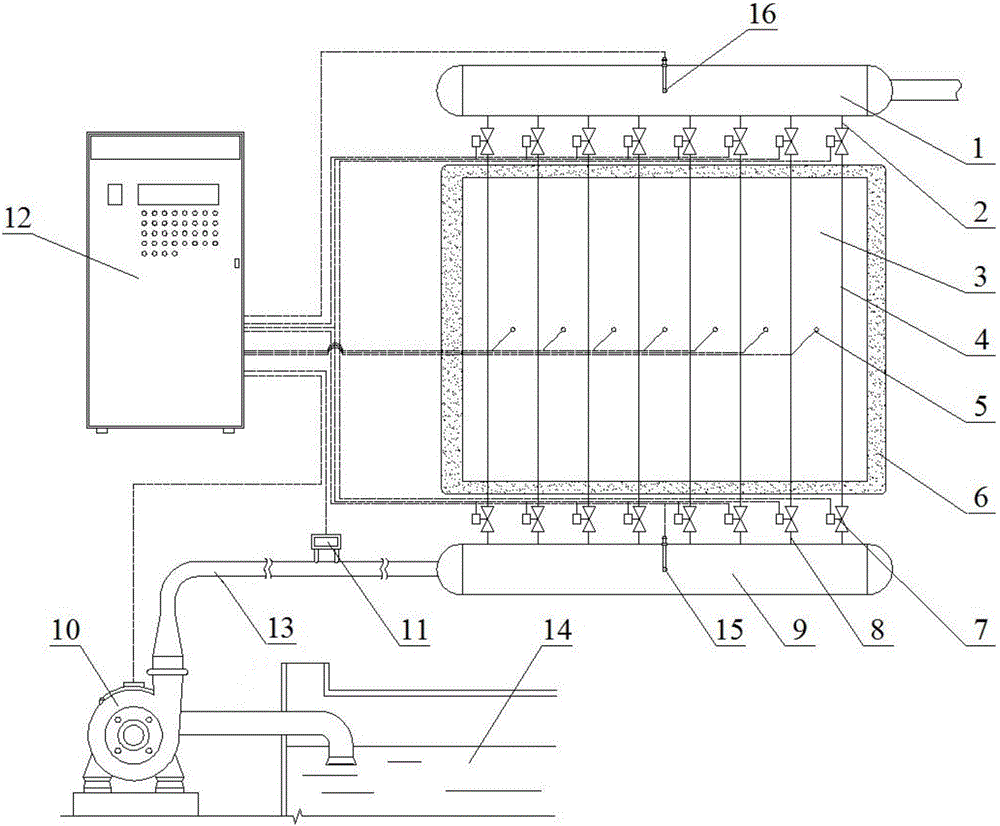

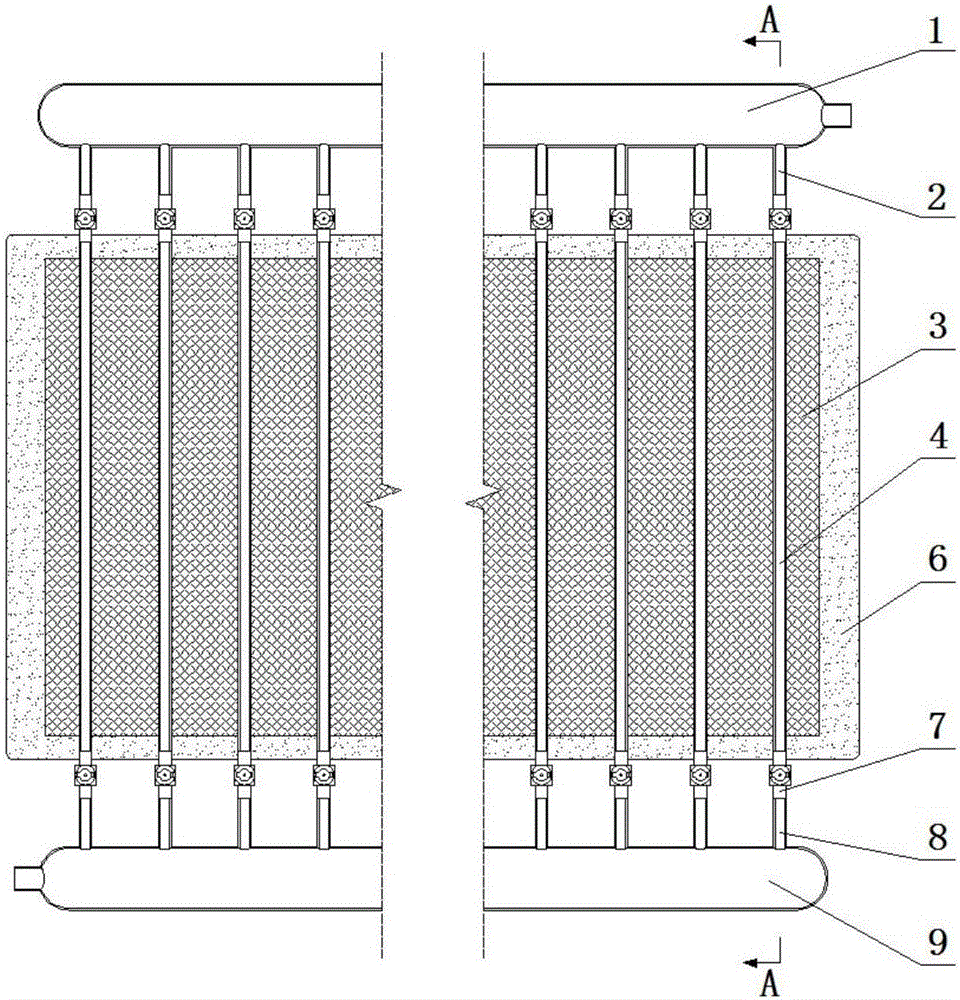

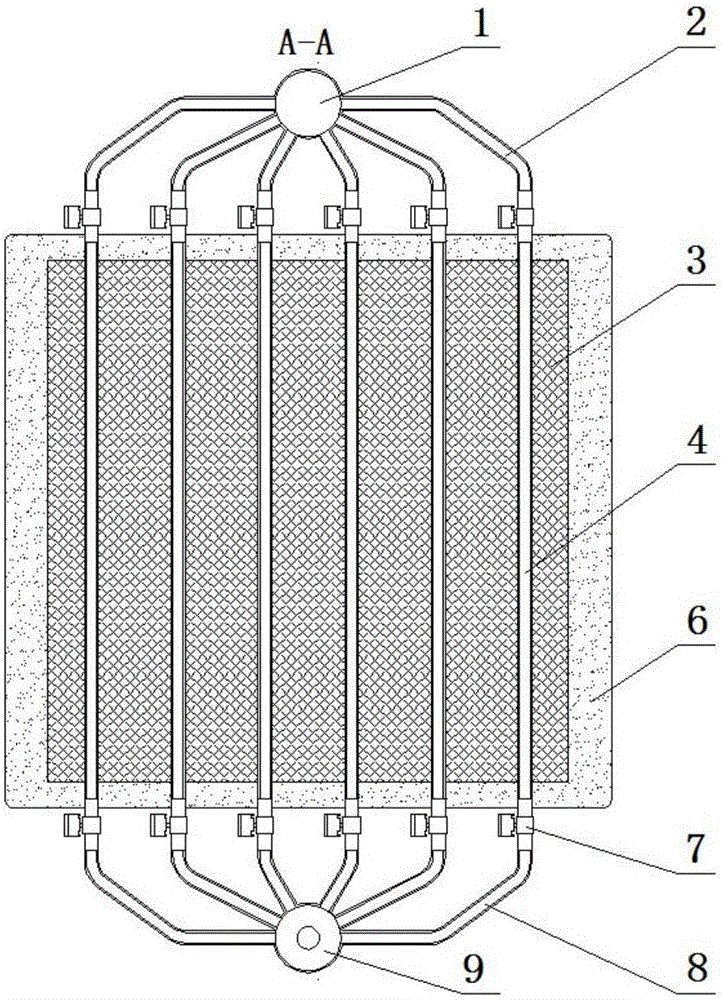

[0033] Such as Figure 1-5 A regenerative direct steam generation system based on parallel regulation is shown, which is characterized in that it includes an outlet header 1, an outlet connecting pipe 2, a heat storage body 3, a heat exchange tube bundle 4, a first temperature sensor 5, and a sealing insulation layer 6. Electric valve 7, inlet connecting pipe 8, inlet header 9, circulating water pump 10, flow meter 11, control cabinet 12, water supply connecting pipe 13, reservoir 14, second temperature sensor 15, third temperature sensor 16; A heat exchange tube bundle 4 is installed in the heat storage body 3, and the heat storage body 3 is installed with a sealed insulation layer 6. The heat exchange tube bundle 4 is connected in parallel with the inlet header 9 and the outlet header respectively through the inlet connecting pipe 8 and the outlet connecting pipe 2. 1 connection, each inlet connecting pipe 8 and outlet connecting pipe 2 are equipped with an independent elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com